Structure for improving quality of epitaxial layer of gallium nitride device and preparation method thereof

An epitaxial structure and gallium nitride technology, which is applied in the field of gallium nitride devices, can solve problems such as leakage reliability, epitaxial wafer warpage, thermal expansion coefficient mismatch, etc., to increase control ability, stabilize epitaxial structure, and balance internal stress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

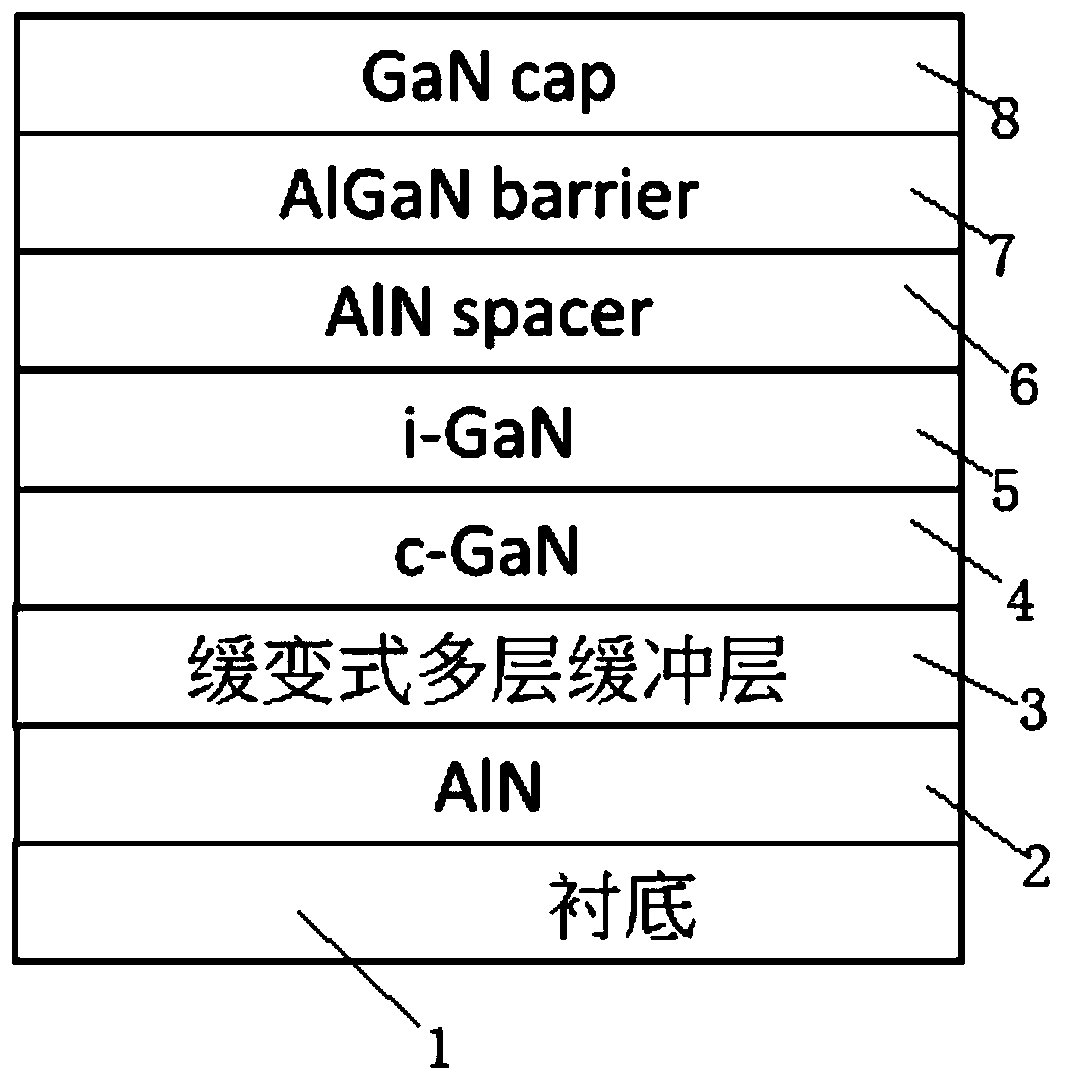

[0029] A method and structure for improving the quality of an epitaxial layer of a gallium nitride device, the operation steps of which are as follows:

[0030] S1, growing an AlN buffer layer 2 on a planar or patterned Si or SiC substrate 1;

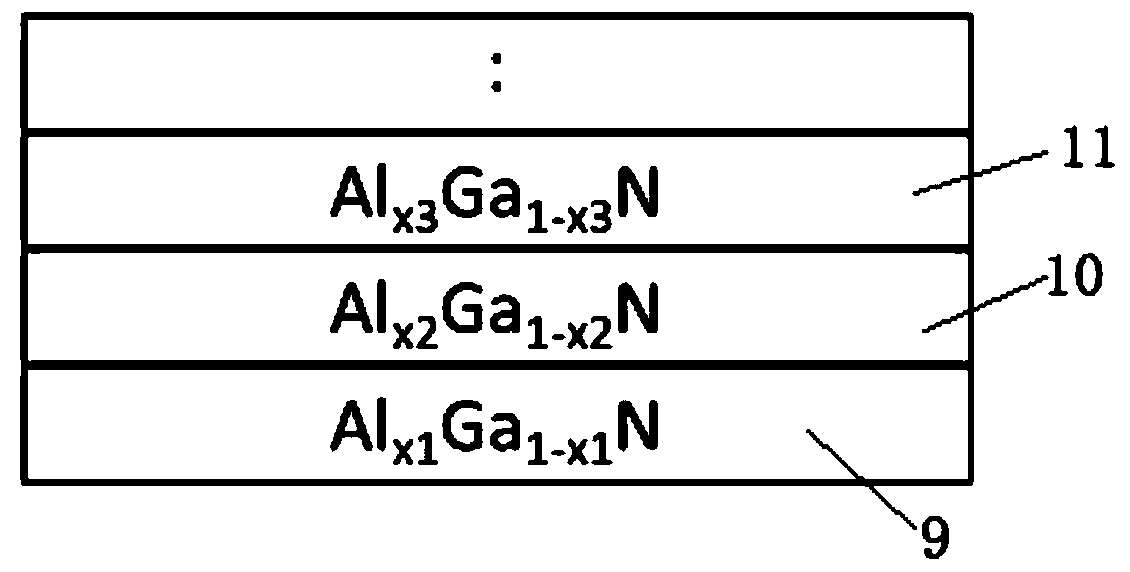

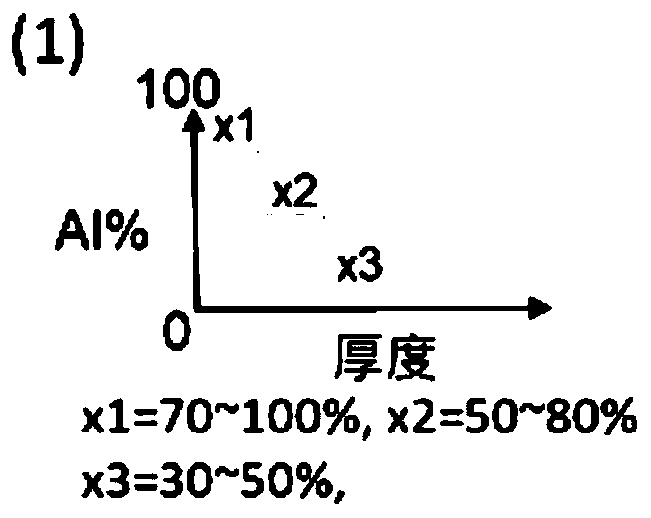

[0031] S2. After the growth of the AlN buffer layer 2 is completed, a slow-change multi-layer buffer layer 3 is grown above it, and the first layer is Al x1 Ga 1-x1 N buffer layer 9, where x1=1~0.7, namely Al 1~0.7 Ga 0~0.3 N, where x1 and 1-x1 represent their corresponding Al and Ga contents, Al x1 Ga 1-x1 The thickness of the N buffer layer 9 is 10-1000nm, which can be adjusted by adjusting Al x1 Ga 1-x1 The thickness of the N buffer layer 9 and the total number of layers of the slow-variable multi-layer buffer layer 3 are 3-10 layers to adjust the stress of the epitaxial structure. According to different epitaxial structure designs, different buffer layers are designed to reduce the difficulty of stress correction;

[0032] S3...

Embodiment 2

[0036] Embodiment 2: Based on Embodiment 1, the difference is:

[0037] A method and structure for improving the quality of an epitaxial layer of a gallium nitride device, the operation steps of which are as follows:

[0038] S1, growing an AlN buffer layer 2 on a planar or patterned Si or SiC substrate 1;

[0039] S2. After the growth of the AlN buffer layer 2 is completed, a slow-change multi-layer buffer layer 3 is grown above it, and the first layer is Al x1 Ga 1-x1 N buffer layer 9, where x1=1~0.7, namely Al 1~0.7 Ga 0~0.3 N, where x1 and 1-x1 represent their corresponding Al and Ga contents, respectively;

[0040] S3, in the first layer of Al x1 Ga 1-x1 After the growth of the N buffer layer 9 is completed, a second buffer layer structure is grown on it, and the second layer is Al x2 Ga 1-x2 N buffer layer 10, where x2=0.8~0.5, namely Al 0.8~0.5 Ga 0.2~0.5 N, where x2 and 1-x2 represent their corresponding Al and Ga contents, respectively;

[0041] S4, in the ...

Embodiment 3

[0053] Embodiment 3: Based on Embodiment 1 and 2, but the difference is:

[0054] Use a planar or patterned Si or SiC substrate 1 to insert a slowly variable multilayer buffer layer 3 between GaN and AlN. The slowly variable multilayer buffer layer 3 is formed by a multilayer AlGaN structure that grows sequentially. Due to the gradual change of the Al content Multi-layer structure, for the high defect density caused by lattice mismatch, it can more effectively solve the problem of lattice dislocation and improve the crystal quality of GaN channel layer more effectively, warpage caused by lattice stress, and thermal expansion mismatch The problem of internal stress accumulation is caused. Because the stress is uniformly processed by the AlGaN structure of each layer in multiple stages, it can be greatly improved, and a more stable epitaxial structure is also formed. The content of Al and Ga in AlGaN in the multilayer AlGaN structure changes slowly. Increase the ability to contr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com