CMT additive manufacturing method for improving tensile property of aluminum alloy

A technology of additive manufacturing and tensile properties, applied in the field of additive manufacturing, can solve problems such as restricting the promotion and application of aluminum alloy products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

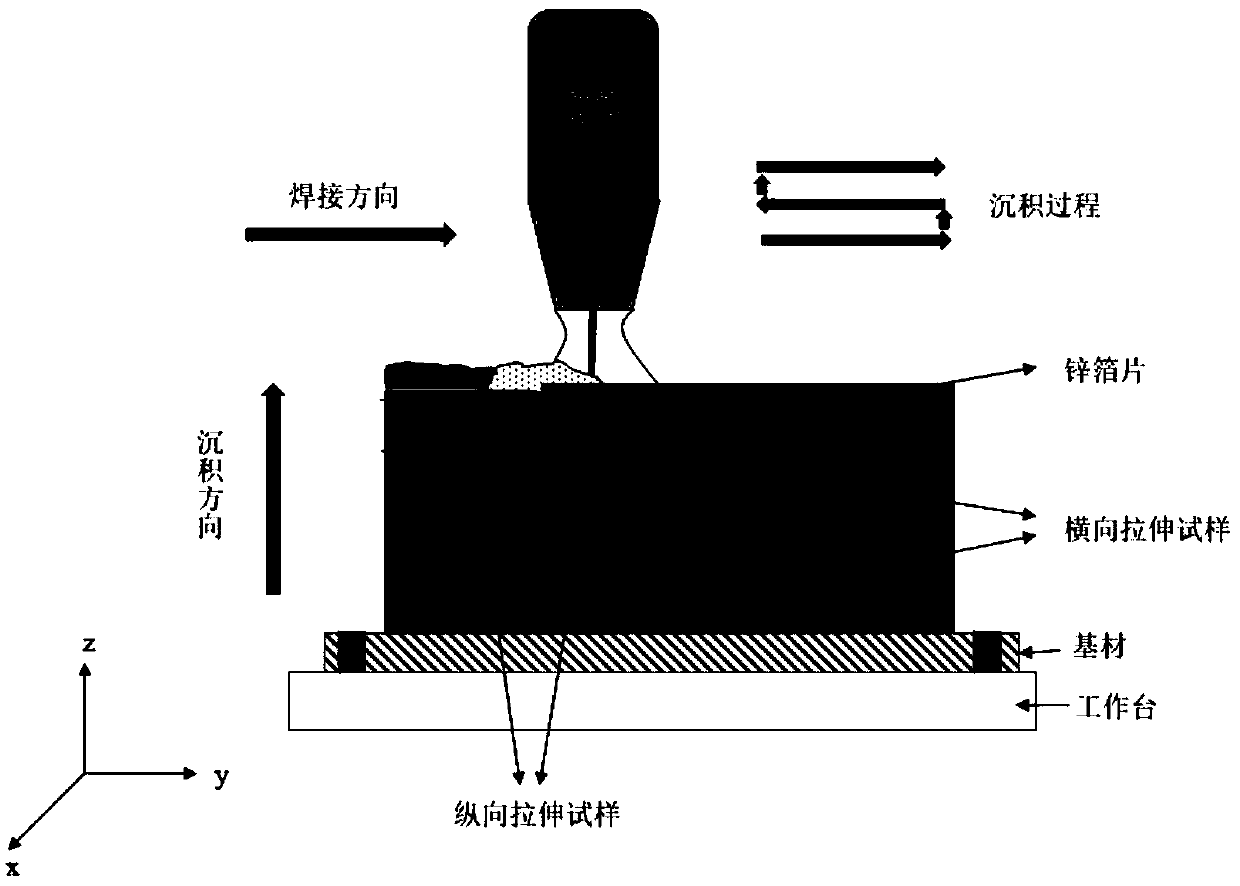

[0015] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

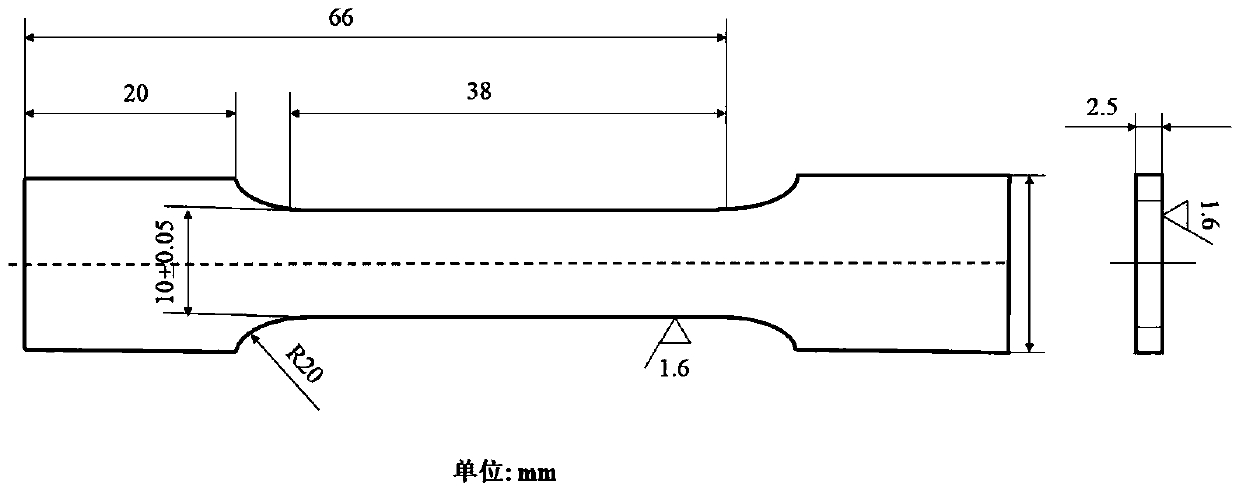

[0016] The test base material involved in the present invention is aluminum alloy 6061, the specification of the test piece is 300×150×4mm, and the welding wire is ER4043. A plate surfacing test was carried out on an aluminum alloy with a plate thickness of 4 mm using DC cold metal transfer technology CMT. The CMT welder used for the test is the CMT Advanced 4000 welder from Fronius. The zinc foil used in the experiment is a metal sheet material with a size of 110×10×0.02mm. The specific chemical composition is shown in the table below.

[0017] Composition (mass percentage, wt%) Zn Al Fe Cd Cu content 99.99 0.005 0.002 0.002 0.001

[0018] Its main implementation steps are as follows:

[0019] 1. Before the surfacing test, use a wire brush to remove the oxide film on the aluminum plate until the metallic luster...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com