Glass fiber reinforced plastic acid storage tank and preparing method

A glass fiber reinforced plastic and acid storage tank technology, which is applied to chemical instruments and methods, glass/slag layered products, containers, etc., can solve the problems of difficult acid drainage, glass fiber reinforced plastic falling off, and difficult cleaning, and achieves good anti-stress effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

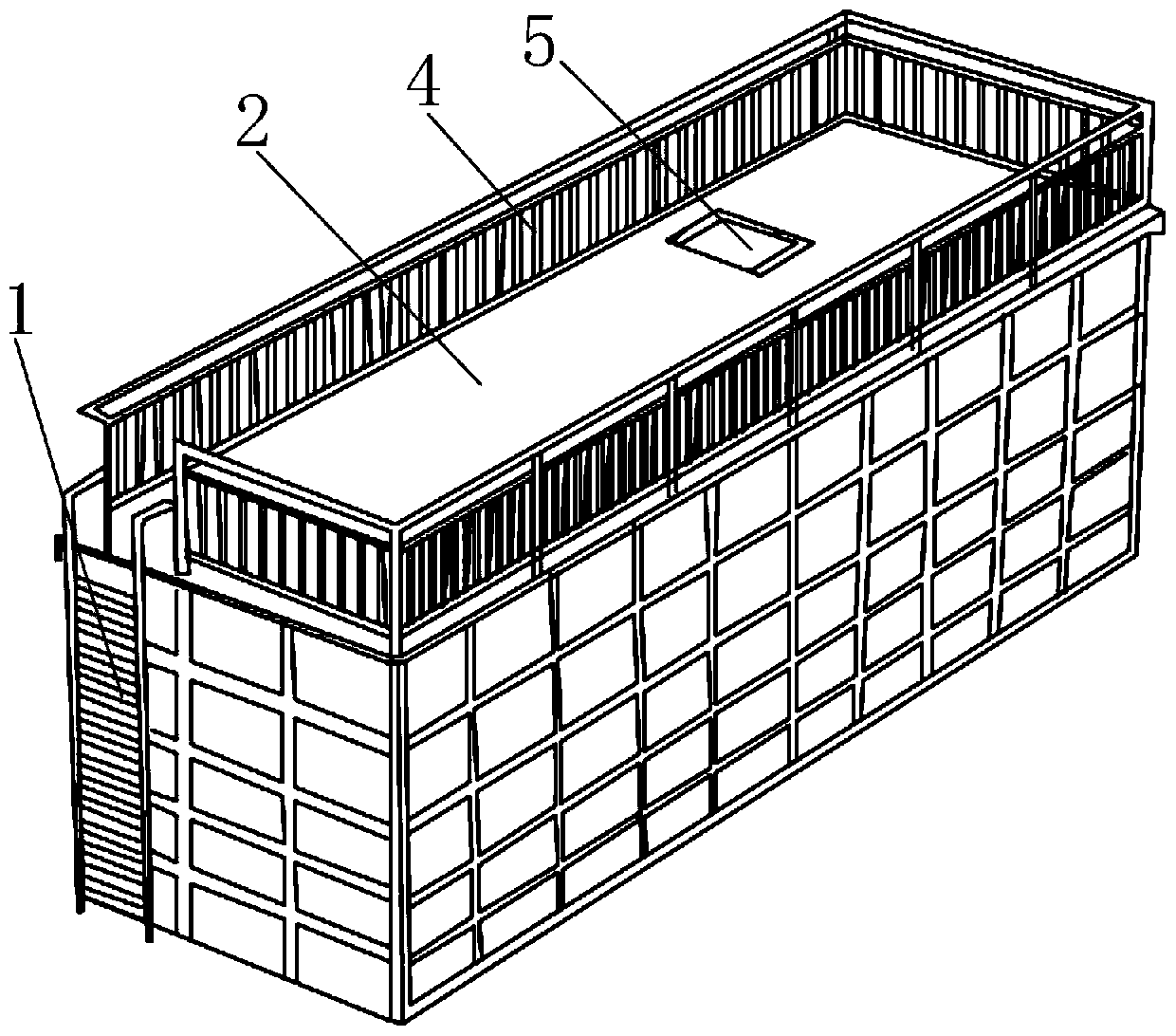

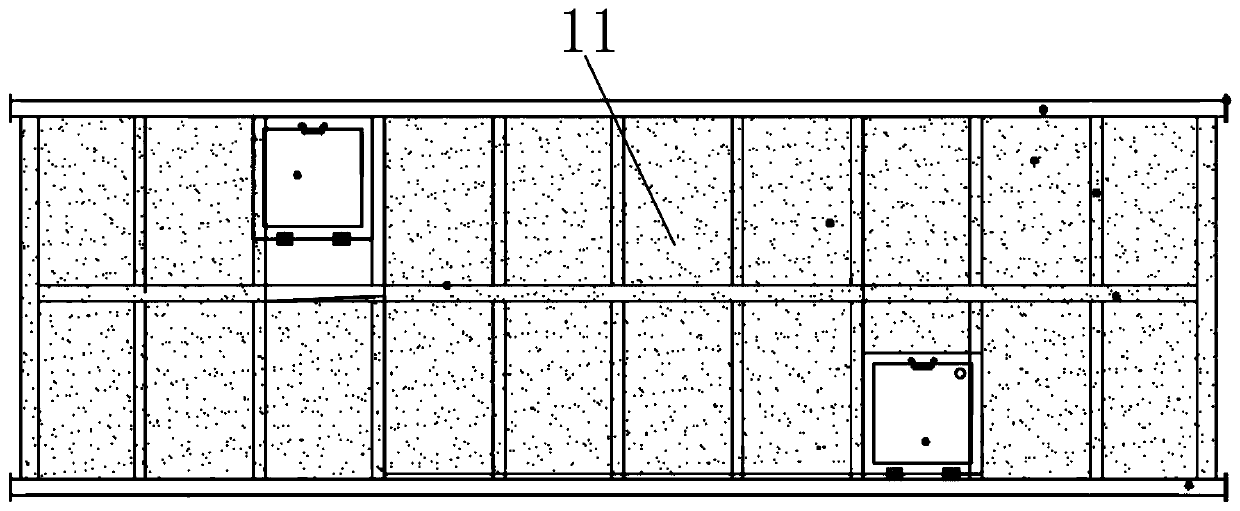

[0052] Such as Figure 1-7 As shown, a glass fiber reinforced plastic acid storage tank includes six side panels, and the six side panels include a first side panel 17, a second side panel 6 opposite to the first side panel, a front panel, a rear panel, a top panel 2 and a bottom panel 15. The six side panels form a hexahedron; each corner of the hexahedron is provided with an arc-shaped filling body 12, and the arc-shaped filling body is made of a paste-like flexible corrosion-resistant adhesive.

[0053] Each side plate includes a support frame 100; one side of the support frame is provided with an adhesive layer 400, a glass steel plate layer 500 and a glass fiber reinforced plastic cloth laminate 60 in sequence; the glass fiber reinforced plastic cloth laminate 60 includes several layers of glass fiber cloth layers 602 ; The adjacent glass fiber cloth layers 602 are bonded by the resin layer 601 .

[0054] Preferably, the support frame can be made of common metal material...

Embodiment 2

[0060] This embodiment is based on Example 1, in order to further enhance the direct adhesive force between the adhesive layer and the support frame, and prevent the support frame and the adhesive layer from being peeled off due to excessive thermal expansion and contraction stress. . In this embodiment, the adhesive layer is improved.

[0061] Such as Figure 8 As shown, the adhesive layer is a flexible and toughened layer, and the flexible and toughened layer is made of a paste-like flexible corrosion-resistant adhesive.

[0062] The paste-like flexible corrosion-resistant adhesive is made by the following preparation method, including steps:

[0063] A. After heating the epoxy resin, dilute it to a fluid state with an epoxy resin diluent to obtain a flowing epoxy resin;

[0064] B, after mixing flow epoxy resin and dibutyl phthalate, obtain flow dynamic toughening resin;

[0065] C. After mixing the fluid dynamic toughening resin with the coupling agent, the fluid dynam...

Embodiment 3

[0087] In order to further solve the technical problem of expansion and cracking of the FRP acid storage tank caused by expansion stress, this embodiment further optimizes the FRP acid storage tank on the basis of Embodiment 2 as follows.

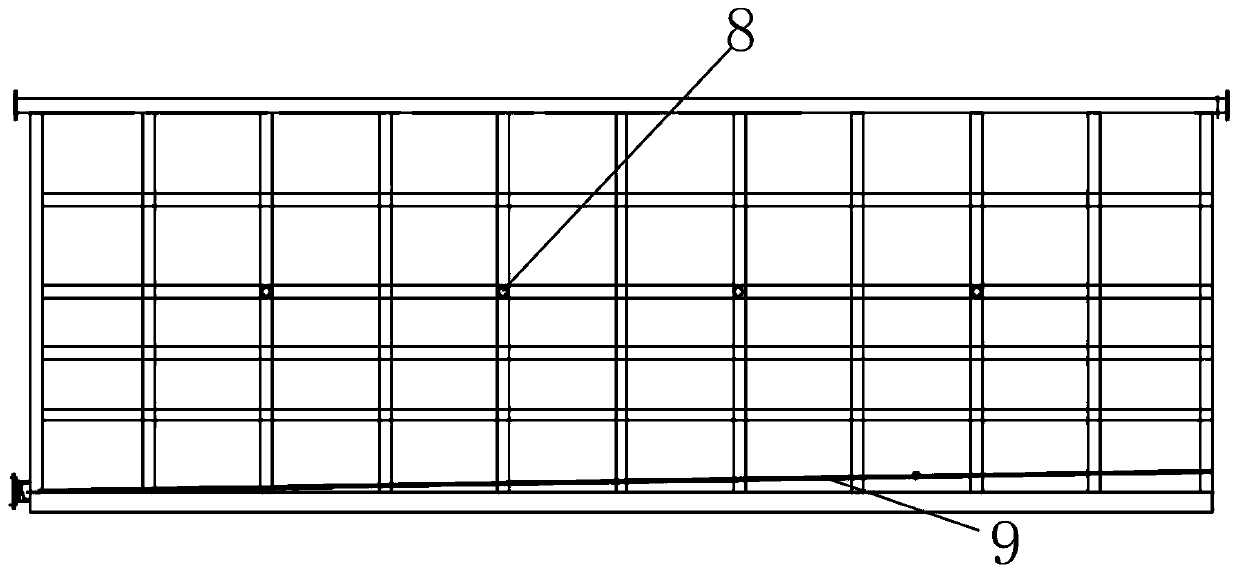

[0088] Such as Figure 1-6 Shown, a kind of FRP acid storage tank, described FRP acid storage tank comprises six side plates, and described six side plates are all made of side plates; Described six side plates comprise first side plate 17, and The second side plate 6, the front plate, the rear plate, the top plate 2 and the bottom plate 15 opposite to the first side plate; the six side plates surround a hexahedron; each corner of the hexahedron is provided with an arc-shaped filling body 12, The curved filling body is made of paste-like flexible corrosion-resistant adhesive. The first side plate is connected with the second side plate through anti-expansion and contraction rods 8 . Such as figure 2Shown in the figure is the connecting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com