Method for preparing maltol and homologue thereof by regulating and controlling chlorination-hydrolysis reaction

A technology of hydrolysis reaction and maltol, applied in directions such as organic chemistry, can solve problems such as low yield, and achieve the effects of reducing production cost, not affecting yield, and easily controlling reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

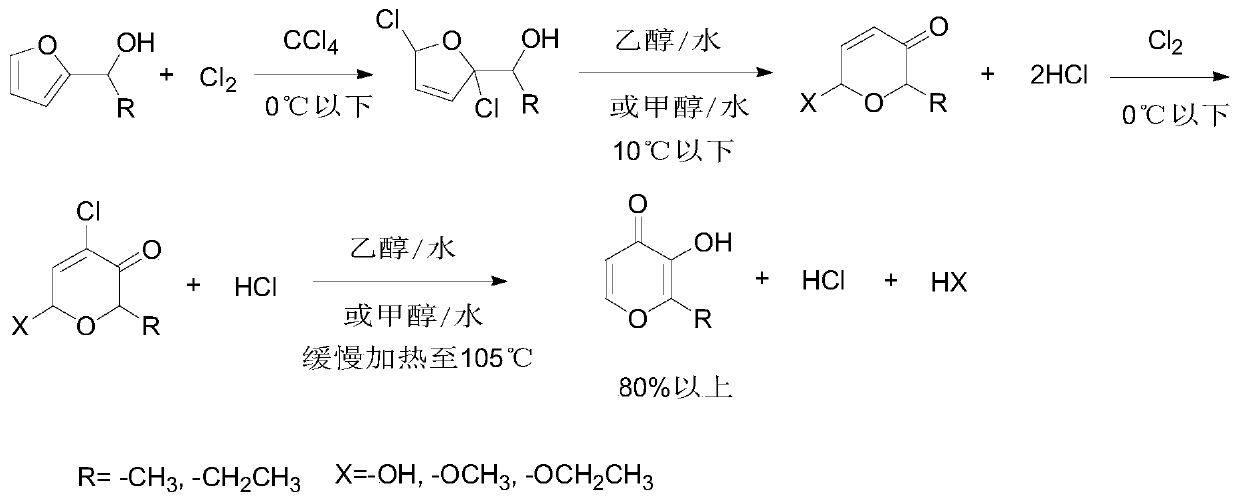

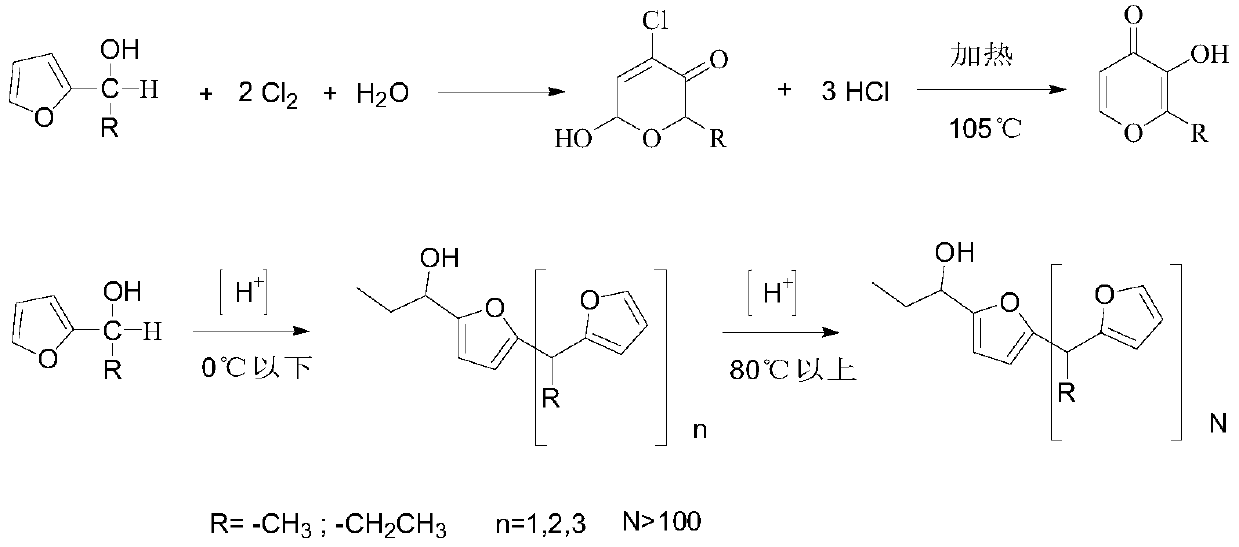

Method used

Image

Examples

Embodiment 1

[0024] A preparation method of methyl maltol, comprising the following steps:

[0025] 1) Put 1 mol of α-furyl methane alcohol in 100 mL of carbon tetrachloride, and then pass through 1 mol of chlorine gas to fully react for 2 hours to generate unstable 2,4-dichloro-α-dihydrofuryl methane alcohol compound;

[0026] 2) Add 55mL of ethanol aqueous solution with 70% ethanol content to the system after the reaction in step 1), and place it at a temperature of 8°C, and react for 50min to generate 6-hydroxy-2-alkyl-1,3-pyridine Ketone compounds;

[0027] 3) Then cool down the reaction system in step 2) to below 0°C, then slowly introduce 1 mol of chlorine gas into the reaction system to generate 2-alkyl-4-chloro-6-hydroxyl-1,3-pyrone compound;

[0028] 4) Slowly heat up the reaction system in step 3) to 60° C., then add 25 mL of ethanol aqueous solution with 50% ethanol content to carry out hydrolysis reaction to obtain methyl maltol.

Embodiment 2

[0030] A preparation method of ethyl maltol, comprising the following steps:

[0031] 1) Put 1 mol of α-furan alcohol in 100 mL of carbon tetrachloride, and then feed 1 mol of chlorine to fully react for 2 hours to generate unstable 2,4-dichloro-α-dihydrofuran alcohol compound;

[0032] 2) Add 55mL of ethanol aqueous solution with 70% ethanol content to the system after the reaction in step 1), and place it at a temperature of 10°C, and react for 60min to generate 6-hydroxy-2-alkyl-1,3-pyridine Ketone compounds;

[0033] 3) Then cool down the reaction system in step 2) to below 0°C, then slowly introduce 1 mol of chlorine gas into the reaction system to generate 2-alkyl-4-chloro-6-hydroxyl-1,3-pyrone compound;

[0034] 4) The system after the reaction in step 3) was slowly heated to 58° C., and then 25 mL of ethanol aqueous solution with an ethanol content of 50% was added for hydrolysis reaction to obtain ethyl maltol.

[0035] After testing, the yields of methyl maltol an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com