Method for processing heavy oil by combined process

A combined process and heavy oil technology, which is applied in the treatment of hydrocarbon oil, hydrotreating process, petroleum industry, etc., and can solve problems such as complex operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

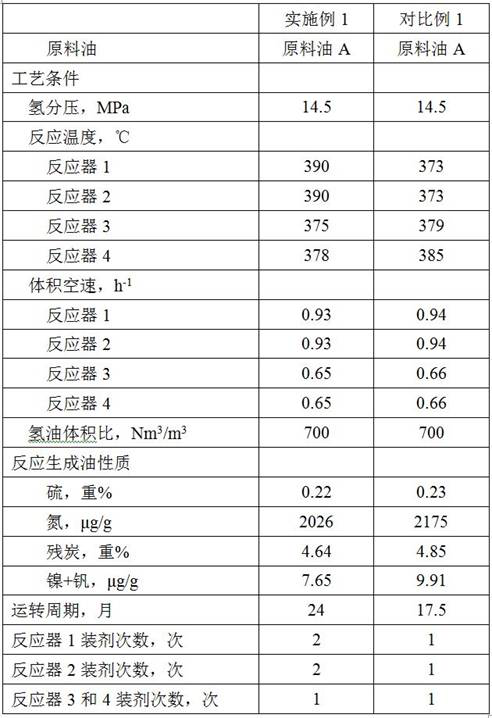

Embodiment 1

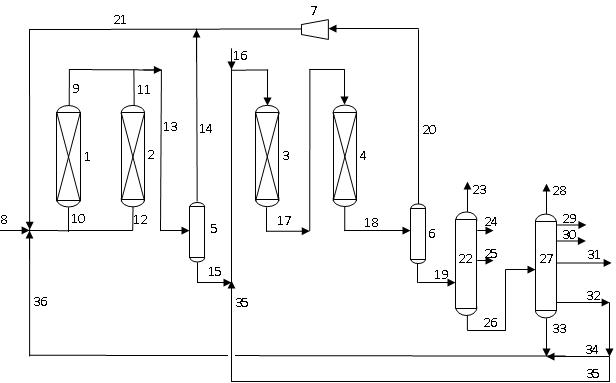

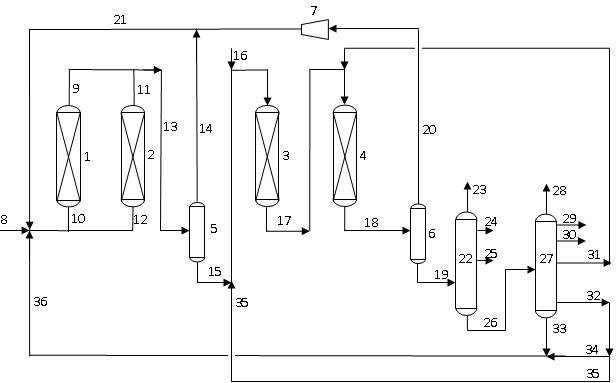

[0081] according to figure 1 In the process flow, the hydrogenation pretreatment reaction zone includes a switchable first hydrogenation pretreatment reaction zone and a second hydrogenation pretreatment reaction zone, the first hydrogenation pretreatment reaction zone is provided with a reactor 1, and the second hydrogenation pretreatment reaction zone is provided with a reactor 1. A reactor 2 is arranged in the second hydrogenation pretreatment reaction zone, and the hydrogenation treatment reaction zone includes a reactor 3 and a reactor 4 arranged in series. According to the material flow direction, the reactor in the hydrogenation pretreatment reaction zone (only one hydrogenation pretreatment reaction zone is online during operation) is filled with catalyst A, catalyst B and catalyst C, and the loading volume ratio of each catalyst is 2:7 : 1. Catalyst B and Catalyst C are installed in the reactor 3 of the hydrotreating reaction zone, and the loading volume ratio of the...

Embodiment 2

[0087] according to figure 1In the process flow, the hydrogenation pretreatment reaction zone includes a switchable first hydrogenation pretreatment reaction zone and a second hydrogenation pretreatment reaction zone, the first hydrogenation pretreatment reaction zone is provided with a reactor 1, and the second hydrogenation pretreatment reaction zone is provided with a reactor 1. A reactor 2 is arranged in the second hydrogenation pretreatment reaction zone, and the hydrogenation treatment reaction zone includes a reactor 3 and a reactor 4 arranged in series. According to the material flow direction, the reactor in the hydrogenation pretreatment reaction zone (only one hydrogenation pretreatment reaction zone is online during operation) is filled with catalyst A, catalyst B and catalyst C, and the loading volume ratio of each catalyst is 3:6 : 1. Catalyst B and catalyst C are housed in hydrotreating reaction zone reactor 3, and the loading volume ratio of two kinds of catal...

Embodiment 3

[0090] according to figure 1 In the process flow, the hydrogenation pretreatment reaction zone includes a switchable first hydrogenation pretreatment reaction zone and a second hydrogenation pretreatment reaction zone, the first hydrogenation pretreatment reaction zone is provided with a reactor 1, and the second hydrogenation pretreatment reaction zone is provided with a reactor 1. A reactor 2 is arranged in the second hydrogenation pretreatment reaction zone, and the hydrogenation treatment reaction zone includes a reactor 3 and a reactor 4 arranged in series. According to the material flow direction, the reactor in the hydrogenation pretreatment reaction zone (only one hydrogenation pretreatment reaction zone is online during operation) is filled with catalyst A, catalyst B and catalyst C, and the loading volume ratio of each catalyst is 4:5 : 1. Catalyst B and Catalyst C are installed in the reactor 3 of the hydroprocessing reaction zone, and the filling volume ratio of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com