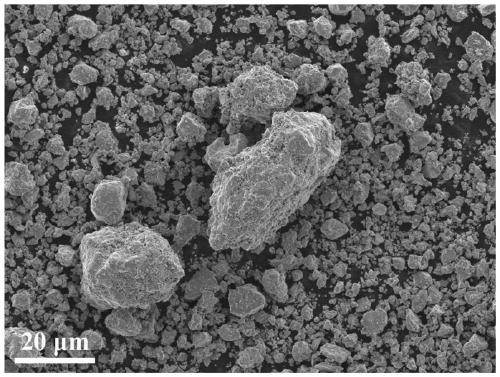

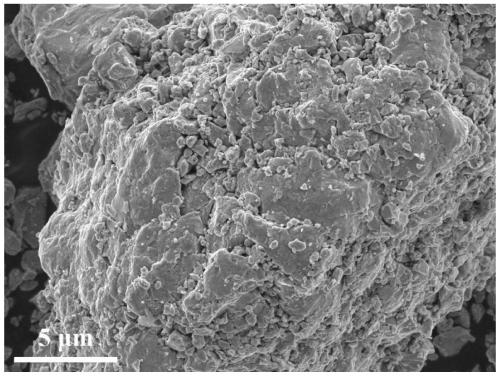

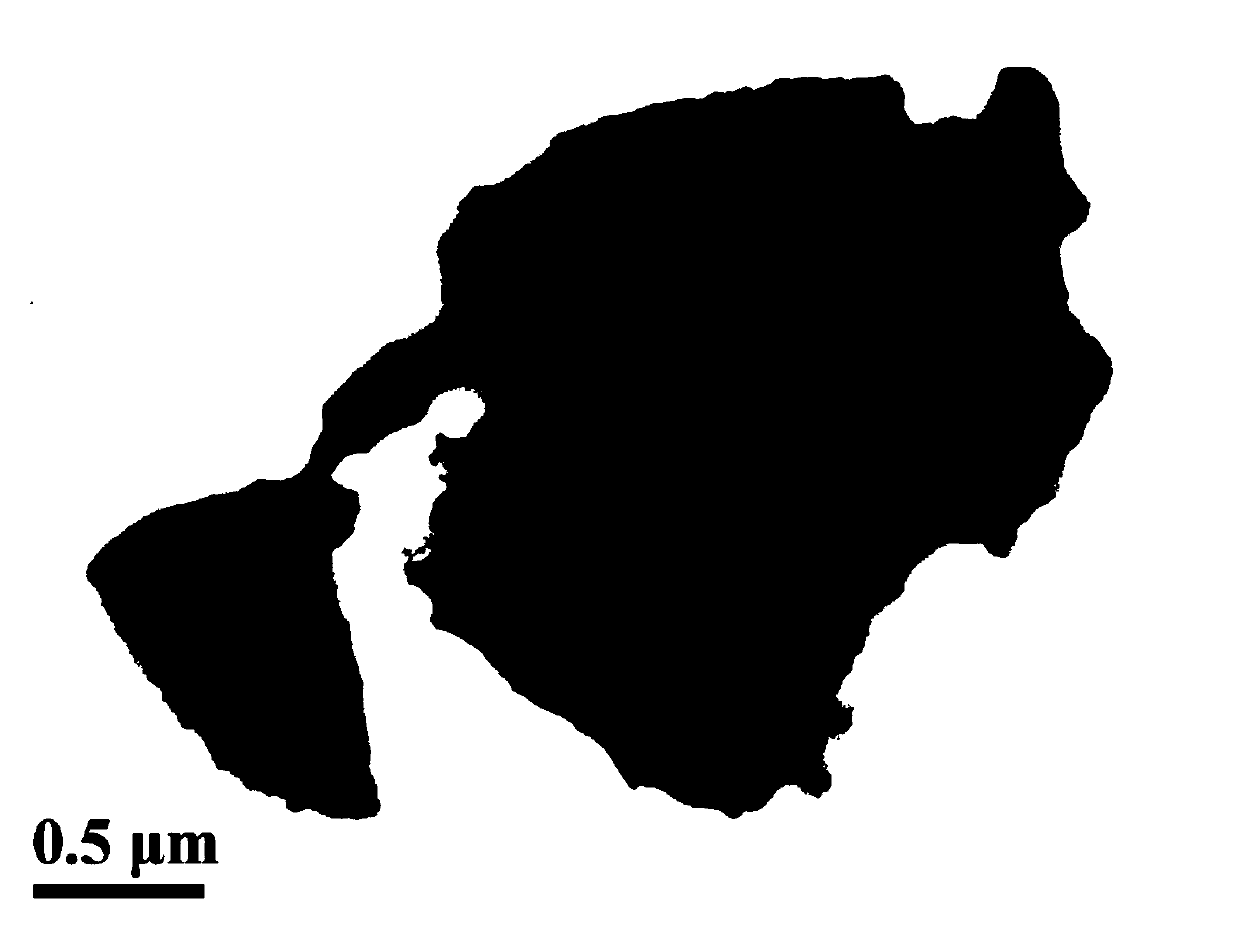

A kind of nanometer iron nitride wave absorbing material with multi-scale grains and preparation method thereof

An iron nitride absorption, multi-scale technology, applied in metal material coating process, solid diffusion coating, coating and other directions, can solve the problem of low total grain boundary area of particles, thick absorbing matching thickness, low scattering frequency, etc. problem, to achieve the effect of simple generation equipment, thin absorbing matching thickness, and wide absorbing frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A preparation method of a nano-iron nitride wave-absorbing material with multi-scale crystal grains, comprising the following steps:

[0037] Step 1: Prepare ferroalloy powder material to be nitrided

[0038] According to the chemical composition of the raw material, weigh the raw material, and use the vacuum atomization powder making equipment to make the raw material into a ferroalloy powder with uniform composition to be nitrided. The average particle size is 50-100 μm; the chemical composition ratio of the raw material is according The mass percentage is: Fe is 99.995%, and the balance is unavoidable impurities;

[0039] Step 2: Nitriding

[0040] Use a gas nitriding furnace to carry out gas nitriding treatment on ferroalloy powder to be nitrided at 480°C to obtain the nitrided material. Use a programmable nitrogen potential controller to control the reaction nitrogen potential, and the nitriding potential is controlled to 1.6 , the nitriding time is 10h;

[0041...

Embodiment 2

[0051] A preparation method of a nano-iron nitride wave-absorbing material with multi-scale crystal grains, comprising the following steps:

[0052] Step 1: Prepare ferroalloy powder material to be nitrided

[0053] According to the chemical composition of the raw materials, the raw materials are weighed, and the raw materials are made into ferroalloy powder to be nitrided by vacuum atomization pulverization equipment. Cr: 10%, Ni: 10%, the balance is Fe and unavoidable impurities;

[0054] Step 2: Nitriding

[0055] Use a gas nitriding furnace to carry out gas nitriding treatment on the iron alloy powder material to be nitrided at 650°C to obtain the nitrided material, and use a programmable nitrogen potential controller to control the reaction nitrogen potential. The nitriding potential is controlled to 0.8, and the nitriding Nitrogen time is 5h;

[0056] Step 3: High Energy Ball Milling

[0057] Put the nitrided material into the ball mill tank, and fill it with high-pu...

Embodiment 3

[0063] A preparation method of a nano-iron nitride wave-absorbing material with multi-scale crystal grains, comprising the following steps:

[0064] Step 1: Prepare ferroalloy powder material to be nitrided

[0065] According to the chemical composition of the raw materials, the raw materials are weighed, and the raw materials are made into ferroalloy powder to be nitrided by vacuum atomization pulverization equipment, with a particle size of 50-100 μm; wherein, the chemical composition ratio of the raw materials is as follows: Mo: 5%, Mn: 2%, the balance is Fe and unavoidable impurities;

[0066] Step 2: Nitriding

[0067] Use a gas nitriding furnace to carry out gas nitriding treatment on the iron alloy powder material to be nitrided at 640°C to obtain the nitrided material. Use a programmable nitrogen potential controller to control the reaction nitrogen potential. The nitriding potential is controlled at 0.4, Nitrogen time is 8h;

[0068] Step 3: High Energy Ball Millin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com