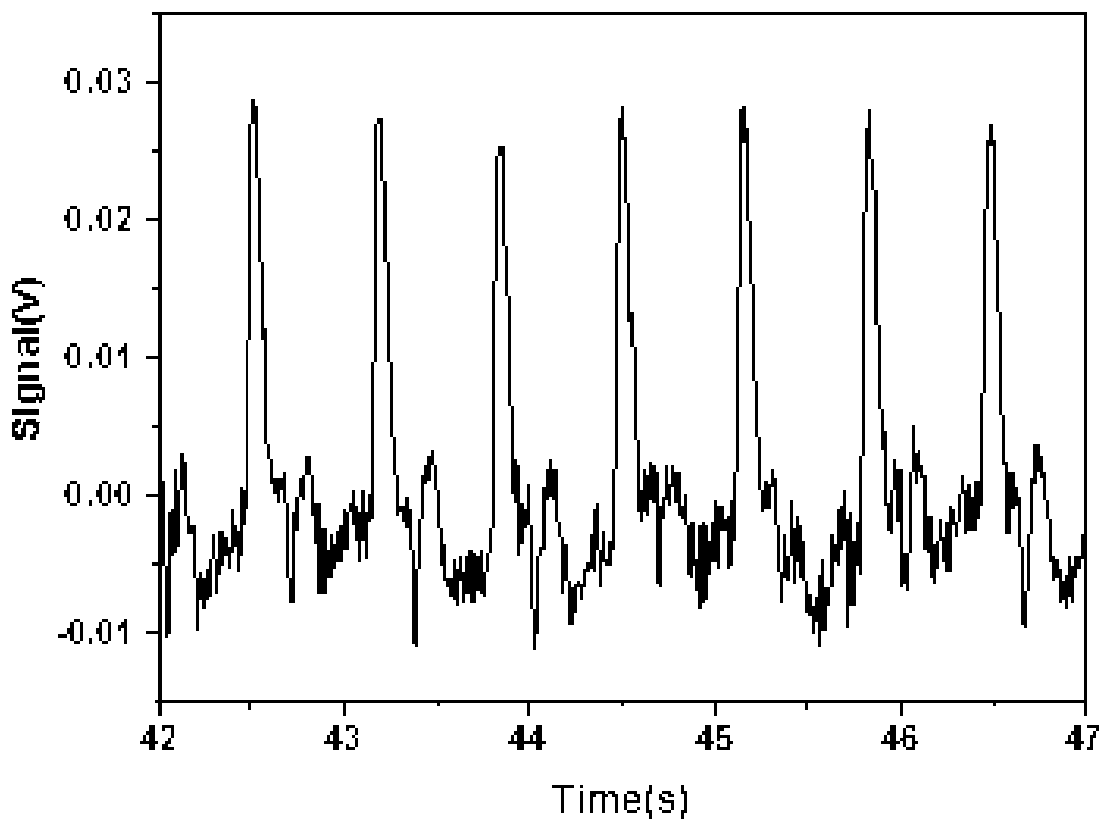

Preparation of flexible pressure sensor for monitoring motion signal and human body pulse signal

A technology of pressure sensor and pulse signal, which is applied in the measurement and application of sensors and piezoelectric devices, can solve the problems that it is difficult to further improve the output performance of friction nanogenerators, it is unfavorable for large-scale production, and the equipment is expensive. Achieve real-time monitoring and information feedback, improve electrical output performance, and simplify equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

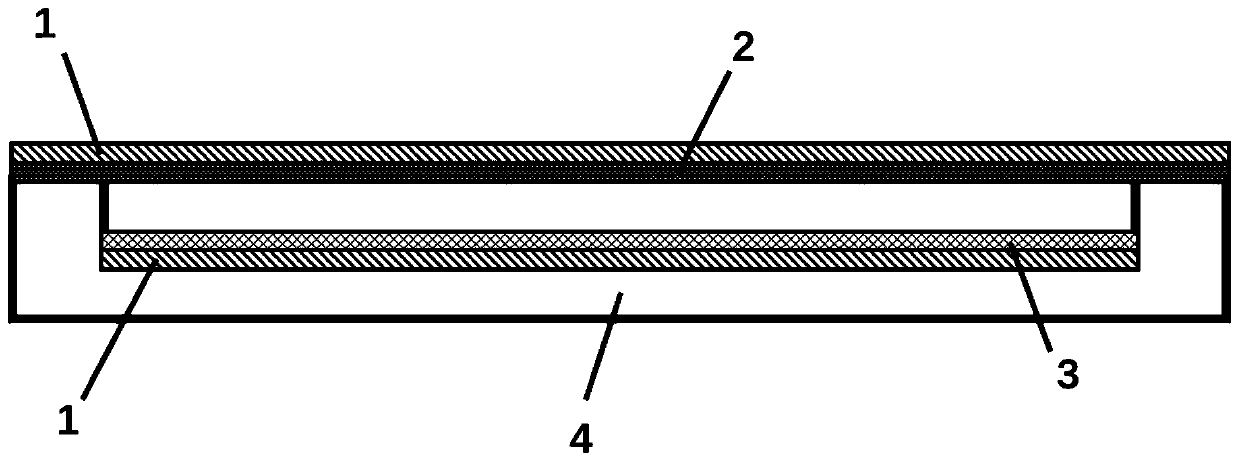

[0042] A method for preparing a flexible pressure sensor for monitoring motion signals and human pulse signals, the specific steps are:

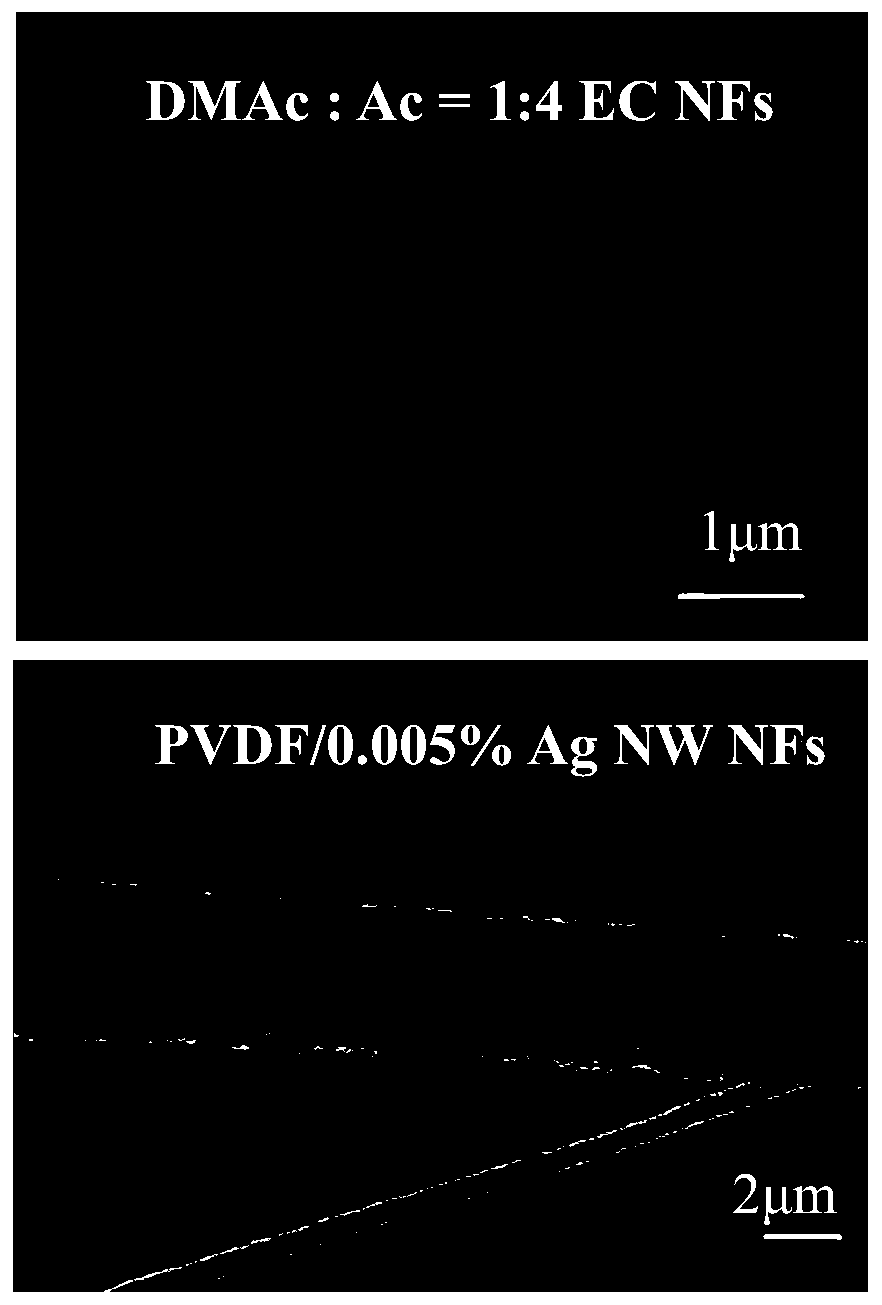

[0043] Step 1: Add ethyl cellulose to a mixed solvent of acetone and polydimethylacetamide (volume ratio: 4 / 1), and keep stirring at 25°C for 30 minutes to prepare a uniform and stable solution with a mass fraction of 30%. Triboelectrically positive polymer spinning solution. Silver nanowires were added to a mixed solvent of acetone and N,N-dimethylformamide (volume ratio: 4 / 6), and ultrasonically treated at 25-40°C for 2 hours to prepare a homogeneous solution with a mass fraction of 0.005%. Then polyvinylidene fluoride powder was slowly added into the solution, and stirred continuously at 50° C. for 2 hours to prepare a triboelectronegative polymer spinning solution with a mass fraction of 15%.

[0044] Step 2: Electrospinning the triboelectrically positive polymer spinning solution and the triboelectrically negative polymer spinning solu...

Embodiment 2

[0051] A method for preparing a flexible pressure sensor for monitoring motion signals and human pulse signals, the specific steps are:

[0052] Step 1: Add ethyl cellulose to a mixed solvent of acetone and polydimethylacetamide (volume ratio: 4 / 1), and keep stirring at 25°C for 30 minutes to prepare a uniform and stable solution with a mass fraction of 35%. Triboelectrically positive polymer spinning solution. Silver nanowires were added to acetone and N,N-dimethylformamide mixed solvent (volume ratio: 4 / 6), ultrasonicated at 25-40°C for 2h to prepare a homogeneous solution with a mass fraction of 0.005%, and then Slowly add polyvinylidene fluoride powder into the solution, and keep stirring at 50° C. for 2 hours to prepare a triboelectronegative polymer spinning solution with a mass fraction of 15%.

[0053] Step 2: Electrospinning the triboelectrically positive polymer spinning solution and the triboelectrically negative polymer spinning solution obtained in step 1 respect...

Embodiment 3

[0059] A method for preparing a flexible pressure sensor for monitoring motion signals and human pulse signals, the specific steps are:

[0060] Step 1: Add ethyl cellulose to a mixed solvent of acetone and polydimethylacetamide (volume ratio: 4 / 1), and keep stirring at 25°C for 30 minutes to prepare a uniform and stable solution with a mass fraction of 35%. Triboelectrically positive polymer spinning solution. Silver nanowires were added to acetone and N,N-dimethylformamide mixed solvent (volume ratio: 4 / 6), ultrasonicated at 25-40°C for 2h to prepare a homogeneous solution with a mass fraction of 0.005%, and then Slowly add polyvinylidene fluoride powder into the solution, and keep stirring at 50° C. for 2 hours to prepare a triboelectronegative polymer spinning solution with a mass fraction of 15%.

[0061] Step 2: Electrospinning the triboelectrically positive polymer spinning solution and the triboelectrically negative polymer spinning solution obtained in step 1 respect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com