Optically uniform transparent conductive film and preparation method thereof

A transparent conductive film, optical technology, applied in optics, equipment for manufacturing conductive/semi-conductive layers, optical components, etc., can solve the problems of obvious etching marks, easy corrosion of metal materials, poor light stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0115] S1, will include 0.01% of nanoparticle B, 0.2% of high viscosity cellulose HPMC as film-forming agent, 0.01% of leveling agent DOW CORNING DC-57, 1% of metal nanowire A and 98.78% of solvent ( Including water, ethanol and isopropanol) mixed uniformly to form a conductive ink; S2, using a slit coating method to coat a conductive ink on a substrate to form a conductive layer; S3, will include 0.02% dendrimer polyamide amine (PAMAM), 0.5% trimethylolpropane trimethacrylate (TMPTMA), 0.2% 1,6-hexanediol diacrylate (HDDA), 0.1% phenoxyethyl acrylate (PHEA ), 0.15% UV absorber BASF Tinuvin 234, 0.09% cellulose acetate butyrate (CAB), 0.08% antioxidant Irganox 1098, 8% diacetone alcohol, 83.51% isopropanol, 7% ethanol , 0.3% photoinitiator DAROCUR1173 and 0.05% IRGACURE2595 are mixed evenly to form a protective layer formula liquid; S4, coating the protective liquid on the surface of the conductive layer, and forming a protective layer after thermal curing or UV curing. Final...

Embodiment 2

[0117] S1, including 0.01% of nanoparticle B, 0.2% of high viscosity cellulose CMC as a film-forming agent, 0.01% of leveling agent DOW CORNING DC-57, 1.5% of metal nanowire A and 98.28% of solvent ( Including water, ethanol and isopropanol) mixed uniformly to form a conductive ink; S2, using a slit coating method to coat a conductive ink on a substrate to form a conductive layer; S3, including 0.01% dendrimer hydroxyl modified Dendritic polyamidoamine (PAMAM-OH), 0.01% ammonia carboxyl complexing agent is ethylenediaminetetraacetic acid (EDTA), 0.8% trimethylolpropane triacrylate (TMPTA), 0.2% 1,6 -Hexanediol diacrylate (HDDA), 0.1% phenoxyethyl acrylate (PHEA), 0.15% UV absorber BASFTinuvin 234, 0.3% cellulose acetate butyrate (CAB), 0.08% anti Oxidant Irganox 1010, 8% diacetone alcohol, 83% isopropanol, 7% ethanol, 0.3% initiator DAROCUR 1173 and 0.05% IRGACURE 2595 are mixed evenly to form a protective layer formula liquid; S4, on the conductive layer The surface is coate...

Embodiment 3

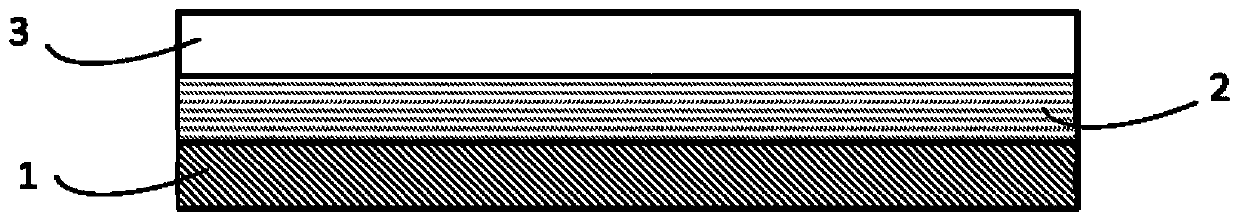

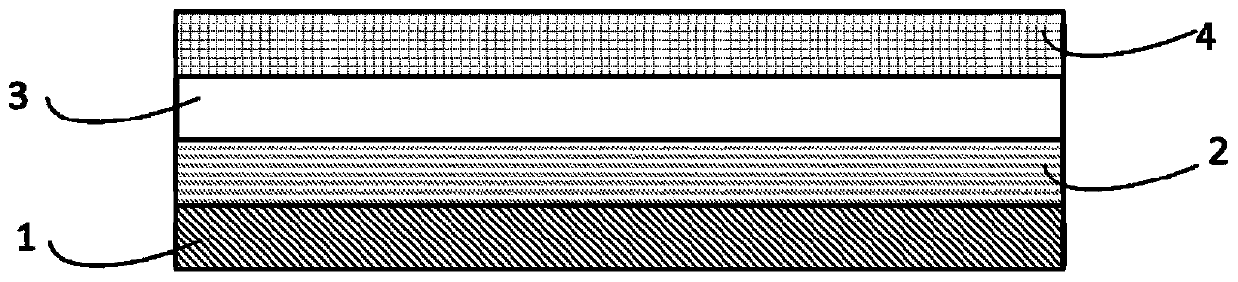

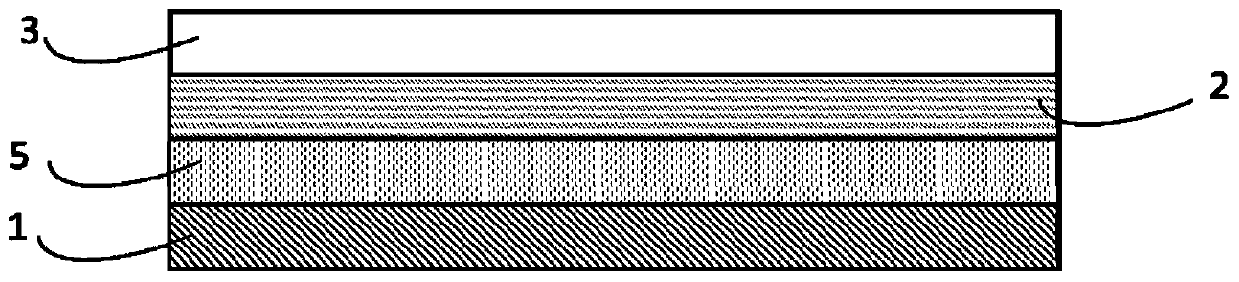

[0119] S1, will include 0.5% of nanoparticles B, 0.8% of high-viscosity cellulose HPMC as a film-forming agent, 0.1% of leveling agent TEGO Glide 410, 1% of metal nanowires A and 97.6% of solvents (including water , ethanol and isopropanol) are mixed evenly to form conductive ink; S2, using slit coating method to coat conductive ink on the substrate to form a conductive layer, such as Figure 5 As shown, metal nanowires A12 and nanoparticles B13 are uniformly distributed on the surface of the substrate to form a planar conductive network; S3, conduct infrared radiation treatment, microwave radiation treatment, xenon lamp pulse treatment, and photon sintering treatment on the conductive layer, and after adjusting the post-treatment Parameters, such as frequency, energy, and processing time, make part of the nanoparticles B in the conductive layer melt and grow secondary, act as a medium, and weld the metal nanowires A, such as Figure 6 a and 6b, as Figure 6 As shown in a, be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com