Ecological farming equipment of fishes and shrimps

An ecological farming, fish and shrimp technology, applied in biological treatment devices, fish farming, biological water/sewage treatment, etc., can solve the problems of no patents and reports, reduce wastewater discharge, improve survival rate and output, reduce The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

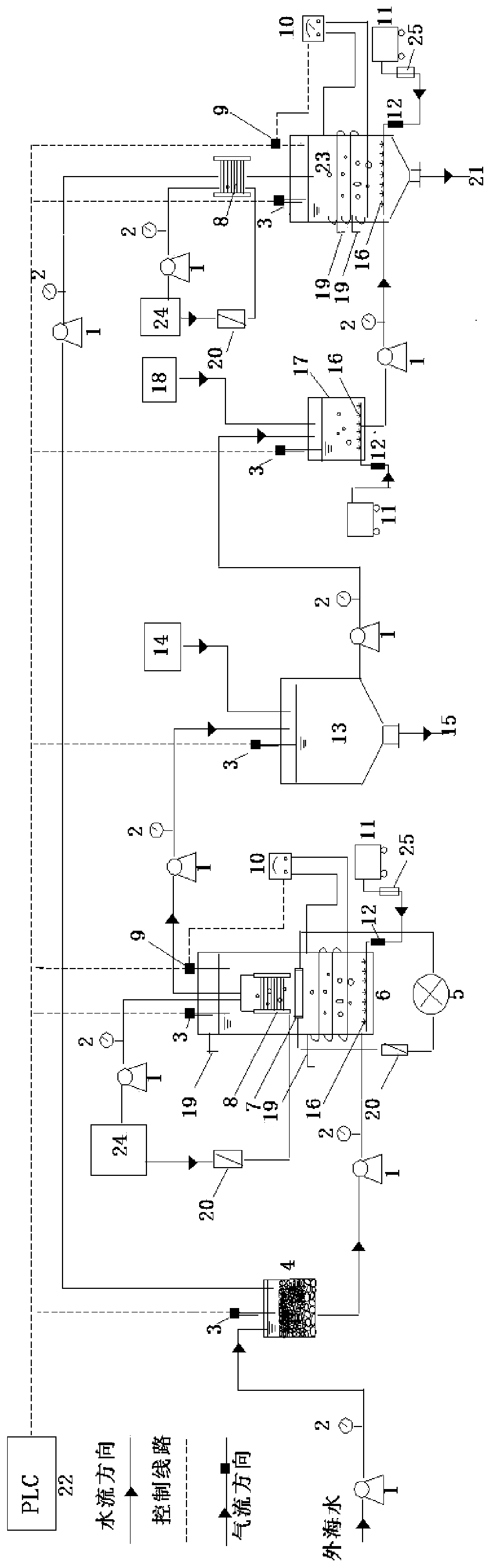

Method used

Image

Examples

preparation example Construction

[0038] The Ag / TiO 2 The preparation method of / PVDF modified film comprises the steps:

[0039] a. PVDF resin powder is dissolved in a solvent, and the solvent is added while stirring evenly to obtain a uniform liquid;

[0040] b. Add nano-Ag and nano-TiO to the homogeneous solution obtained in step a 2 , add dispersant immediately, mix thoroughly and then add pore forming agent;

[0041] c. The solution obtained in step b is defoamed after standing at 25-30°C for 1-3 days;

[0042] d. The defoaming solution obtained in step c is prepared in a membrane machine at a temperature of 15-30°C and a humidity of 60-80% to obtain a reinforced hollow fiber membrane, which is the Ag / TiO 2 / PVDF modified membrane.

[0043] Most preferably, Ag / TiO 2 The components and contents of the PVDF modified film are calculated by mass percentage: 16% for PVDF, 75% for solvent N-N dimethylacetamide, 1% for nano Ag, and 1% for nano TiO 2 1.7%, the pore-forming agent PVP is 3.8%, and the dispersa...

Embodiment 1

[0121] In order to determine nAg / TiO 2 Nano-nAg / TiO in Modified PVDF Ultrafiltration Membrane 2 Effect of mass ratio on contact angle of modified film, choose nAg:TiO 2 = 1:1.0, 1:1.3, 1:1.5, 1:1.7 and 1:1.9 mass ratio, the contact angle test is as follows in Table 1.1.

[0122] Table 1.1 nAg:TiO 2 Changes in contact angle between modified membranes with different mass ratios and ordinary PVDF membranes

[0123]

[0124] As can be seen from Table 1.1, with nAg:TiO 2 The increase in the mass ratio is first reduced to nAg:TiO 2 When =1:1.7, the contact angle is 60.15, which is the smallest value, and the contact angle is 12.72 lower than that of ordinary PVDF film, nAg:TiO 2 The contact angles of modified PVDF with different mass ratios are lower than those of non-modified films.

Embodiment 2

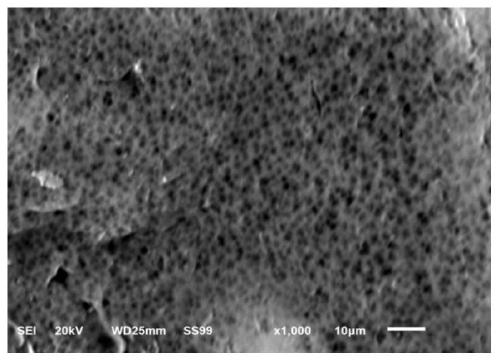

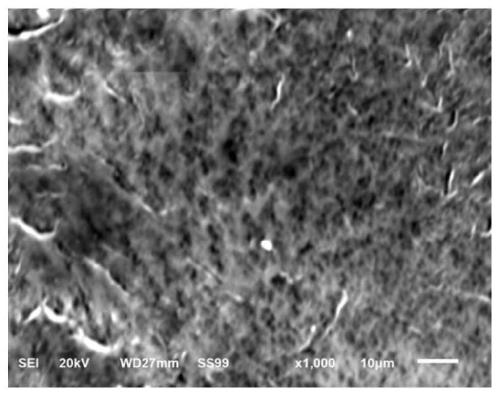

[0126] In order to determine nAg / TiO 2 nAg / TiO in Modified PVDF Ultrafiltration Membrane 2The effect of the optimal mass ratio on the surface roughness of the modified film, the preferred mass of PVDF is 16%, the preferred mass of N-N dimethylacetyl is preferably 75%, the preferred mass of sodium hexametaphosphate is 2.5%, the preferred mass of PVP is 3.8%, and nAg is selected : TiO 2 =1: 1.0, 1: 1.3, 1: 1.5, 1: 1.7 and 1: 1.9 mass ratio prepare series film, its roughness is as follows table 2.1.

[0127] Table 2.1 nAg:TiO 2 Roughness changes between modified membranes with different mass ratios and ordinary PVDF membranes

[0128]

[0129] It can be seen from Table 2.1 that the roughness varies with nAg / TiO 2 The mass ratio shows a certain change trend, but one thing is certain, the roughness of the modified membrane is increased compared with the ordinary PVDF film, and the roughness shows a certain change trend because of the nanometer nAg / TiO 2 The nano-scale parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com