Lonicera japonica water-removing and drying integrated processing device and lonicera japonica processing method

A processing device and technology of honeysuckle, which are applied in the directions of pharmaceutical formulations, plant raw materials, plant/algae/fungus/moss components, etc., can solve the problems of low quality of honeysuckle, inability to guarantee the coherence time of greening and drying, etc., so as to improve the quality, The effect of shortening processing time and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

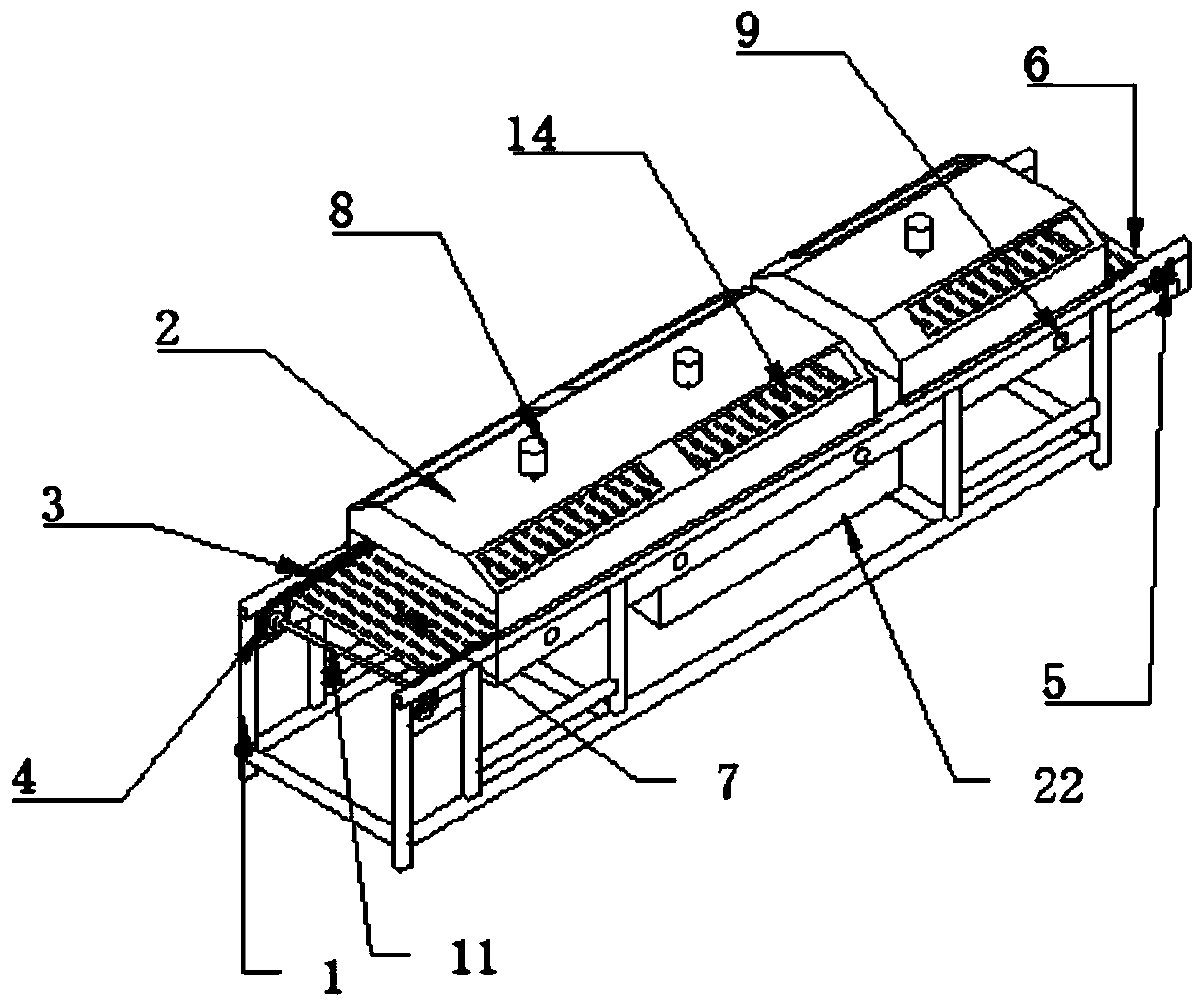

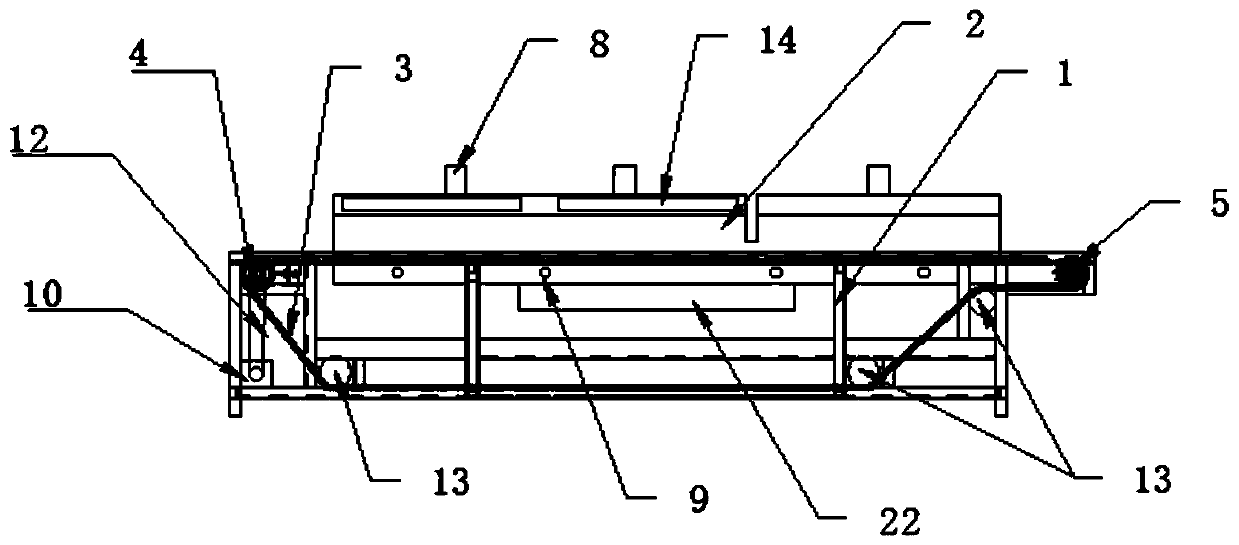

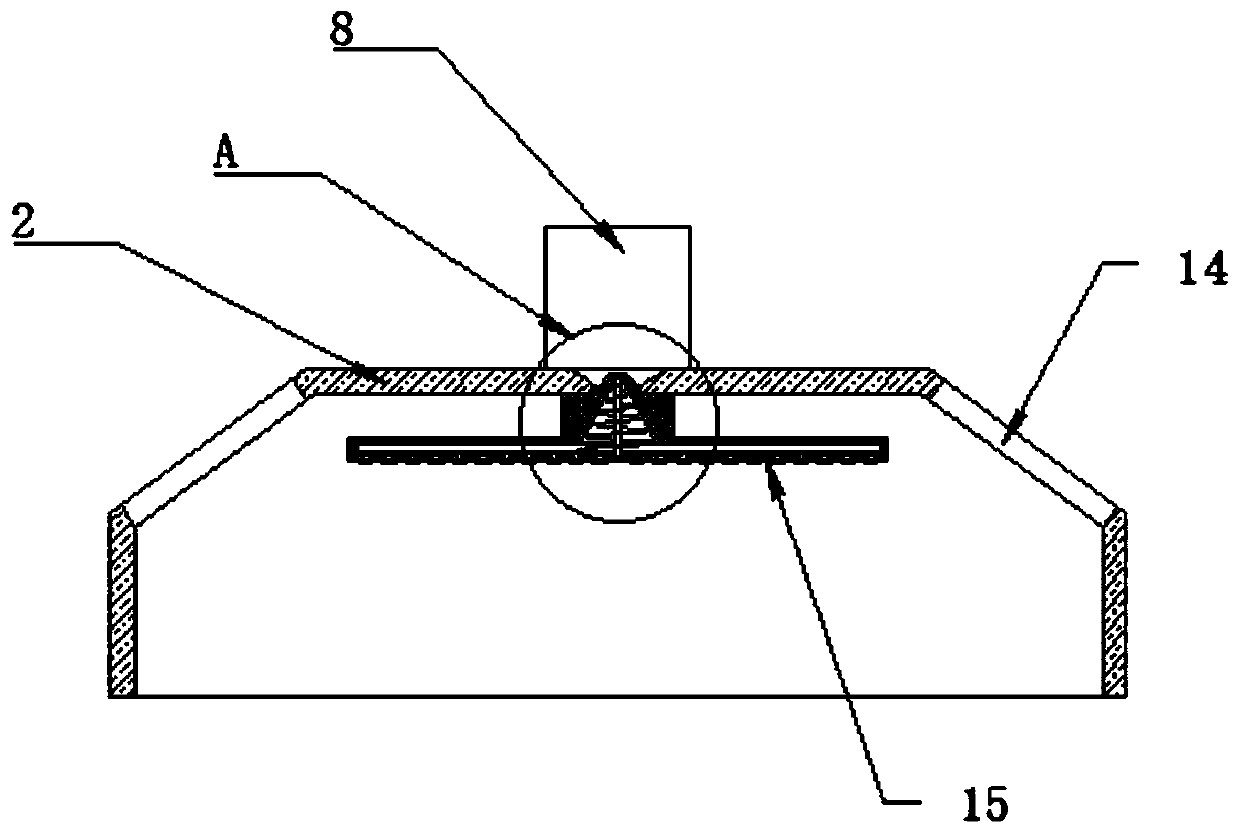

[0029] see Figure 1 to Figure 4 , a honeysuckle fixing and drying integrated processing device, comprising a frame 1, a processing box 2 with openings at both ends is installed on the frame 1, and a pair of driving chains 3 crossing the processing box 2 are also installed on the frame 1 , and the driving chain 3 meshes with the first sprocket 4 and the second sprocket 5 respectively installed at both ends of the frame 1, and the first sprocket 4 and the second sprocket 5 are both rotatably connected with the frame 1; The carrier plate 6 for carrying honeysuckle on the drive chain 3, and the carrier plate 6 is provided with some first through holes 7; the upper wall surface of the processing box 2 is also equipped with an air intake pipe for introducing the green steam that communicates with it 8. On the side wall of the processing box 2, there is also an air inlet 9 for introducing high-temperature drying air under the loading plate 6, and steam and high-temperature air are r...

Embodiment 2

[0039] A kind of honeysuckle processing method, comprises the following steps:

[0040] S1 picks the honeysuckle whose flower buds have not yet opened, spreads it on the loading plate 6, sends it into the processing box 2 through the loading plate 6, introduces high-pressure steam into the processing box 2 through the air intake pipe 8, and sprays it for 2 minutes after stop;

[0041] S2 introduces high-temperature air at 70°C into the processing box 2 through the air inlet 9, and stops after drying for 20 minutes;

[0042] S3 introduces low-temperature gas at 35°C into the processing box 2 through the air inlet 9, stops after drying for 40 minutes, then withdraws from the loading plate 6, and cools to room temperature.

Embodiment 3

[0044]A kind of honeysuckle processing method, comprises the following steps:

[0045] S1 picks the honeysuckle that has not yet opened the flower buds, spreads it on the loading plate 6, sends it into the processing box 2 through the loading plate 6, introduces high-pressure steam into the processing box 2 through the air intake pipe 8, and sprays it for 3.5 stop after min;

[0046] S2 introduces high-temperature air at 65°C into the processing box 2 through the air inlet 9, and stops after drying for 25 minutes;

[0047] S3 introduces low-temperature gas at 40°C into the processing box 2 through the air inlet 9, stops after drying for 35 minutes, then exits the loading plate 6, and cools to room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com