Wet garbage treatment system

A garbage disposal system and installation rack technology, which is applied in grain processing, lighting and heating equipment, drying, etc., can solve the problems of affecting the health of the staff, the high content of wet garbage germs, and increasing the loss of water resources, etc., to increase convenience , reduce weight and take up space, and produce steam quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

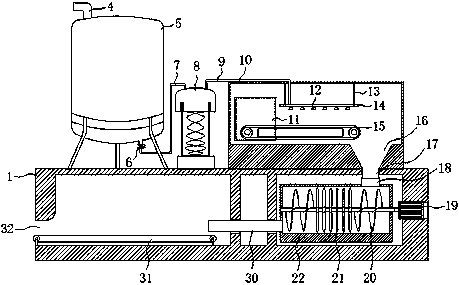

[0027] refer to figure 1 , a wet garbage treatment system, comprising an installation stand 1, the upper end of the installation stand 1 is sequentially installed with a water storage tank 5, an evaporator 8 and a disinfection box 10 from left to right, and the lower end of the water storage tank 5 is fixedly inserted with a water outlet valve 6. The upper end of the water storage tank 5 is fixedly inserted with the water inlet pipe 4, and the first connecting pipe 7 is connected to the water outlet valve 6, and the first connecting pipe 7 is connected to the water inlet end of the evaporator 8, and the water outlet end of the evaporator 8 A second connecting pipe 9 is installed, and the second connecting pipe 9 is inserted in the disinfection box 10;

[0028] The upper top wall of the disinfection box 10 is fixed and symmetrically equipped with a plurality of fixed rods 13, and the lower ends of the plurality of fixed rods 13 are jointly fixed with a spray plate 14, and the l...

Embodiment 2

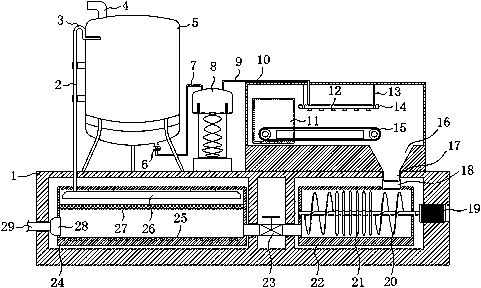

[0035] refer to figure 2 , a wet garbage treatment system, which is basically the same as Embodiment 1, except that:

[0036] A dry discharge box 24 is installed in the discharge cavity, and a valve pipe 23 is fixedly inserted in the pipeline cavity. , the inner top of the drying discharge box 24 is fixedly equipped with a gas collecting hood 26, and the bottom of the gas collecting hood 26 is fixedly equipped with a filter screen 27, so as to prevent the wet garbage from drying and blocking the gas collecting hood 26, and the inner bottom wall of the drying discharge box 24 An electric heating tube 25 is embedded and installed, and a discharge cover 28 is embedded and installed on the side of the drying discharge pipe. There is a return air pipe 2, and the upper end of the return air pipe 2 passes through the upper top wall of the drying discharge box 24 and the upper top wall of the installation stand 1 is located on the side of the water storage tank 5, and the upper end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com