Graphene oxide membrane cross-flow filtration process for treatment of oily sewage

A graphene membrane and cross-flow filtration technology, which is applied in water/sewage treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of easy pollution in the use process, complicated preparation process, and long service life. Short and other problems, achieve the effect of reducing membrane fouling, simple process, and reducing deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

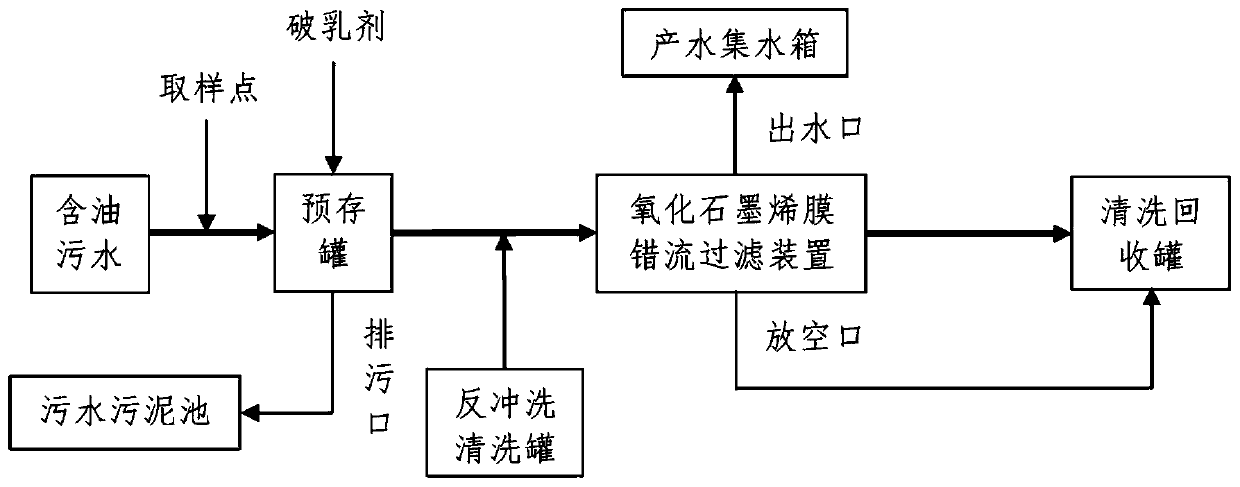

[0022] Such as figure 1 As shown, the invention discloses a graphene oxide membrane cross-flow filtration process for oily sewage treatment, which specifically comprises the following steps:

[0023] (1) Inject the oily sewage into the pre-storage tank, add a demulsifier into the pre-storage tank, and the tank is equipped with a stirring device to make the oil in the sewage completely free.

[0024] (2) Send the stagnant sewage to the graphene oxide membrane cross-flow filtration device through the lifting pump, and transport the sludge to the sewage sludge tank through the bottom sewage outlet.

[0025] (3) Cross-flow filtration is carried out through the graphene oxide membrane, and the produced water is transported from the water outlet to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com