Preparation method of superabsorbent resin and application of superabsorbent resin in reducing moisture content of muck

A technology of super absorbent resin and dregs, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of throwing and dripping, reducing the moisture content of dregs, and decreasing the water absorption rate, so as to reduce the moisture content and improve the water retention. , the effect of facilitating outbound transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

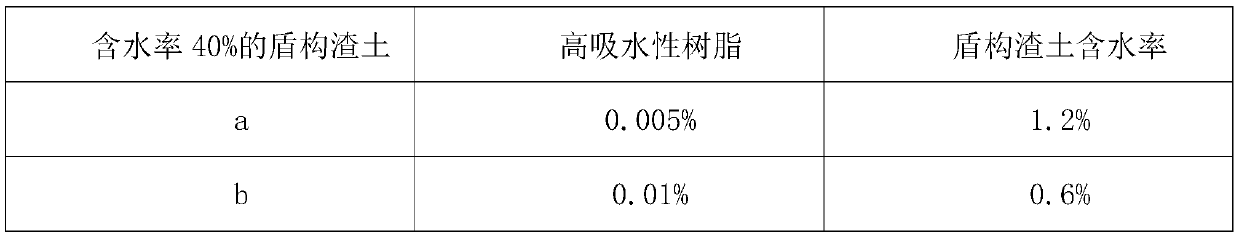

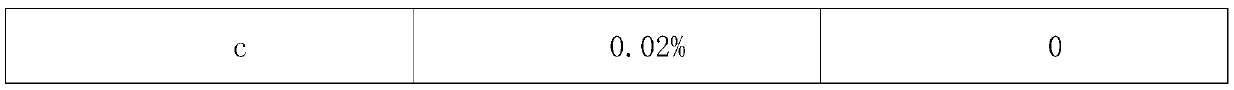

Examples

Embodiment 1

[0026] A preparation method of a superabsorbent resin, the steps are as follows: Hydroxide is neutralized with acrylic acid to prepare an acrylic acid monomer solution, and under the action of a crosslinking agent, an initiator, a catalyst, cellulose and a surfactant, it is polymerized by crosslinking React to prepare superabsorbent resin.

[0027] As a preferred solution of this embodiment, it specifically includes the following steps:

[0028] A. In an ice-water bath, slowly drop a certain amount of hydroxide aqueous solution into acrylic acid, and the degree of neutralization is 40%, to obtain an aqueous solution of acrylate monomer containing acrylate and part of acrylic acid;

[0029] B, cellulose is mixed with a certain amount of distilled water, surfactant is added in the process of stirring, and heating obtains transparent aqueous solution;

[0030] C. Add the aqueous solution of acrylic acid monomer prepared in step A dropwise to the transparent solution prepared in ...

Embodiment 2

[0044] A preparation method of a superabsorbent resin, the steps are as follows: acrylic acid monomer solution is prepared by neutralizing hydroxide with acrylic acid, and prepared by polymerization reaction under the action of crosslinking agent, initiator, catalyst, cellulose and surfactant The preparation method of superabsorbent resin.

[0045]As a preferred solution of this embodiment, it specifically includes the following steps:

[0046] A. In an ice-water bath, slowly drop a certain amount of aqueous hydroxide solution into acrylic acid, and the degree of neutralization is 90%, to obtain an aqueous solution of acrylic acid monomer containing acrylate and acrylic acid;

[0047] B, cellulose is mixed with a certain amount of distilled water, surfactant is added in the process of stirring, and heating obtains transparent aqueous solution;

[0048] C. Add the aqueous solution of acrylic acid monomer prepared in step A dropwise to the transparent solution prepared in step ...

Embodiment 3

[0062] A preparation method of a superabsorbent resin, the steps are as follows: acrylic acid monomer solution is prepared by neutralizing hydroxide with acrylic acid, and prepared by polymerization reaction under the action of crosslinking agent, initiator, catalyst, cellulose and surfactant The preparation method of superabsorbent resin.

[0063] As a preferred solution of this embodiment, it specifically includes the following steps:

[0064] A. In an ice-water bath, slowly drop a certain amount of aqueous hydroxide solution into acrylic acid, the degree of neutralization is 60%, to obtain an aqueous solution of acrylic acid monomer containing acrylate and acrylic acid;

[0065] B, cellulose is mixed with a certain amount of distilled water, surfactant is added in the process of stirring, and heating obtains transparent aqueous solution;

[0066] C. Add the aqueous solution of acrylic acid monomer prepared in step A dropwise to the transparent solution prepared in step B u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com