Class B1 flame-retardant single-component polyurethane foam material

A polyurethane foam, one-component technology, applied in the field of building materials, can solve the problems that the single-component polyurethane foam cannot be guaranteed for long-term use, cannot reach the B1 flame retardant grade, and has poor flame retardant effect, so as to ensure long-term use and enhance resistance. combustion effect, the effect of improving the oxygen index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

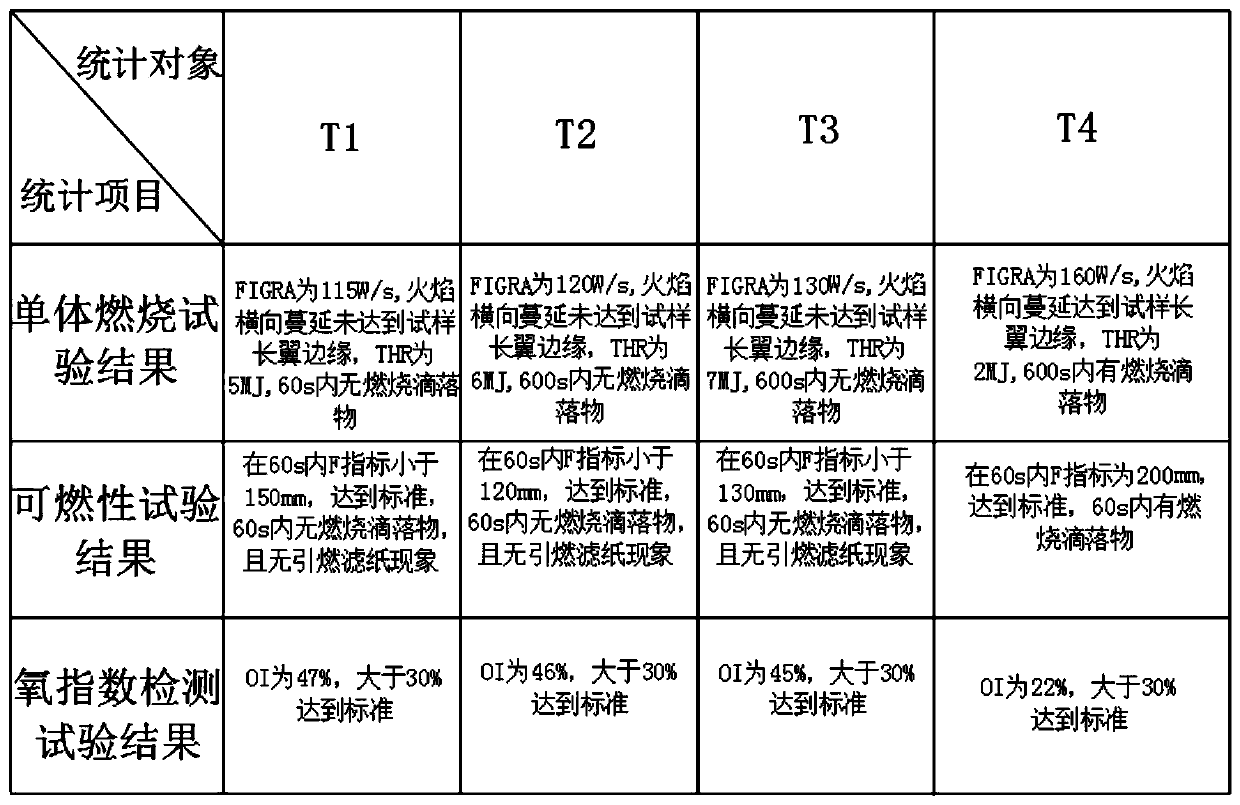

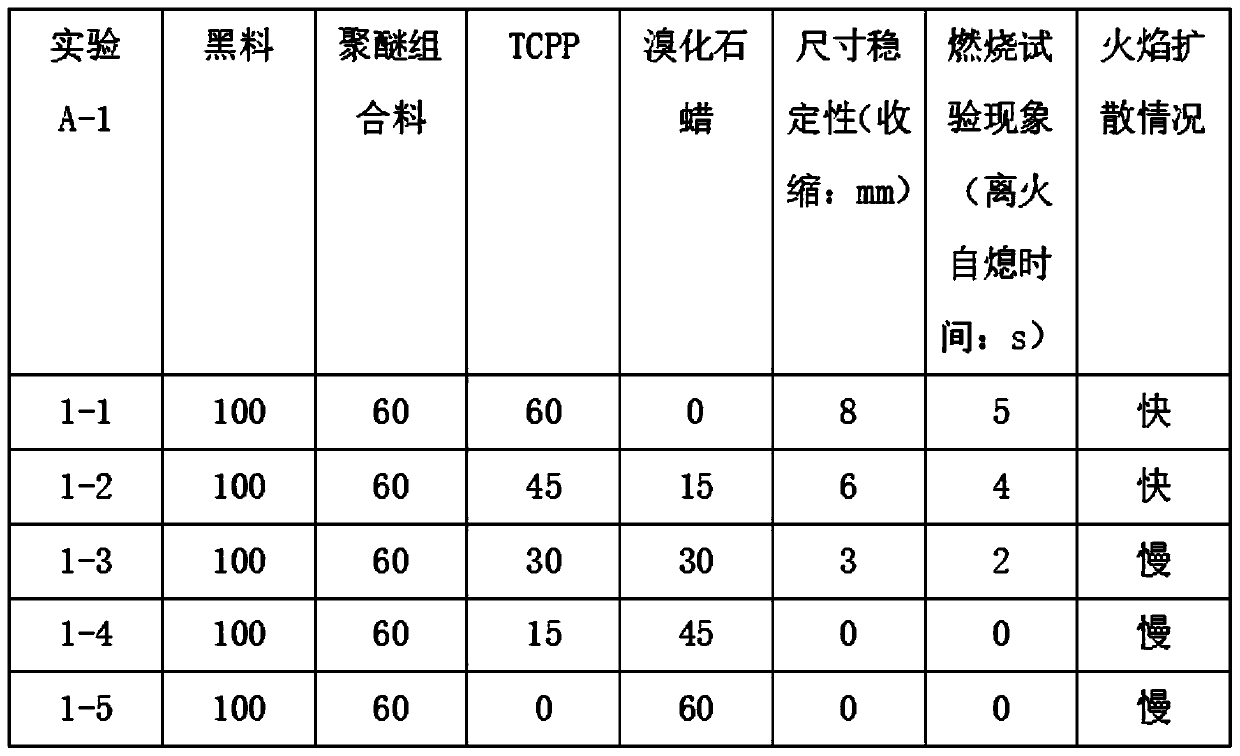

Examples

Embodiment 1

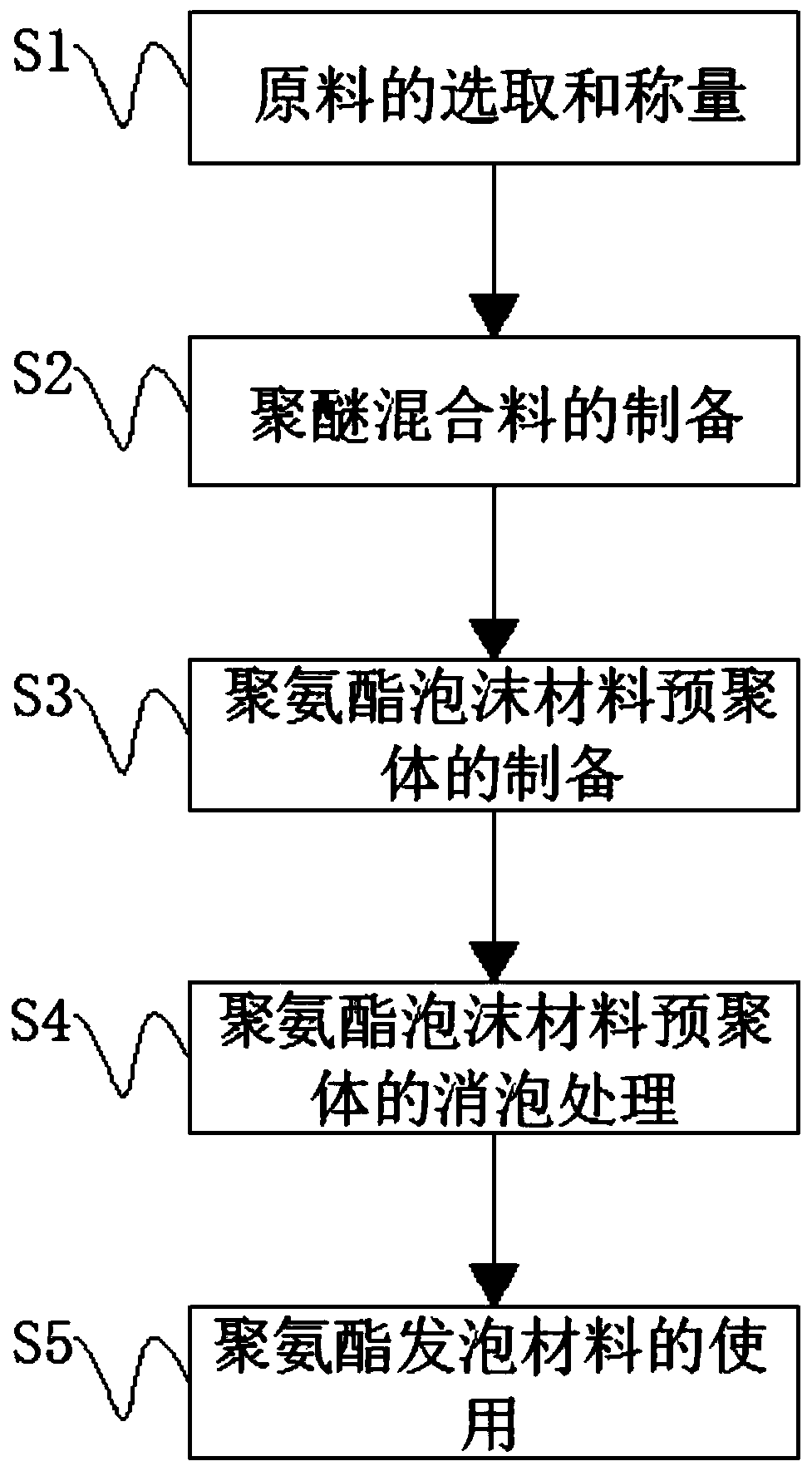

[0037] S1. Selection and weighing of raw materials: first use weighing equipment to measure 100 parts of diphenylmethane diisocyanate, 95 parts of mixed flame-retardant polyether polyol, 7 parts of flame-retardant paraffin, and 7 parts of corresponding parts by weight. 134a hydrofluoroalkane propellant, 3 parts catalyst and 3 parts B1 flame retardant foaming agent. After the measurement is completed, diphenylmethane diisocyanate, hybrid flame retardant polyether polyol, flame retardant paraffin, 134a hydrofluoro Alkane propellant, catalyst and B1 flame retardant blowing agent are placed in storage tanks for storage and use;

[0038] S2. Preparation of polyether mixture: Pour the mixed flame-retardant polyether polyol, flame-retardant paraffin, 134a hydrofluoroalkane propellant and catalyst measured in step S1 into the mixing stirrer in turn at a speed of 550r / min , Stir for 35 minutes at a temperature of 30°C to prepare a polyether mixture;

[0039] S3. Preparation of polyurethane...

Embodiment 2

[0043] S1. Selection and weighing of raw materials: first use weighing equipment to measure 15 parts of diphenylmethane diisocyanate, 110 parts of mixed flame-retardant polyether polyol, 5 parts of flame-retardant paraffin, and 5 parts of corresponding parts by weight. 134a hydrofluoroalkane propellant, 1 part catalyst and 1 part B1 flame retardant foaming agent. After the measurement is completed, diphenylmethane diisocyanate, mixed flame retardant polyether polyol, flame retardant paraffin, 134a hydrofluoro Alkane propellant, catalyst and B1 flame retardant blowing agent are placed in storage tanks for storage and use;

[0044] S2. Preparation of polyether mixture: Pour the mixed flame-retardant polyether polyol, flame-retardant paraffin, 134a hydrofluoroalkane propellant and catalyst measured in step S1 into the mixing stirrer in turn at a speed of 500r / min , Stir for 30 minutes at a temperature of 26°C to prepare a polyether mixture;

[0045] S3. Preparation of polyurethane fo...

Embodiment 3

[0049] S1. Selection and weighing of raw materials: First, use weighing equipment to measure 150 parts of diphenylmethane diisocyanate, 80 parts of mixed flame-retardant polyether polyol, 10 parts of flame-retardant paraffin, and 10 parts by weight respectively. 134a hydrofluoroalkane propellant, 5 parts catalyst and 5 parts B1 flame retardant foaming agent. After the measurement is completed, diphenylmethane diisocyanate, hybrid flame retardant polyether polyol, flame retardant paraffin, 134a hydrofluoro Alkane propellant, catalyst and B1 flame retardant blowing agent are placed in storage tanks for storage and use;

[0050] S2. Preparation of polyether mixture: Pour the mixed flame-retardant polyether polyol, flame-retardant paraffin, 134a hydrofluoroalkane propellant and catalyst measured in step S1 into the mixing stirrer in turn at a speed of 600r / min , Stir for 40 minutes at a temperature of 35°C to prepare a polyether mixture;

[0051] S3. Preparation of polyurethane foam m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com