Heavy metal fixing agent and in-situ remediation method for heavy metal polluted soil

A technology of heavy metals and fixatives, applied in the restoration of polluted soil, soil conditioning materials, chemical instruments and methods, etc., can solve the problems of process control, low treatment efficiency, large amount of use, etc., to achieve inhibition of growth and reproduction, treatment High efficiency and the effect of preventing pests and diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

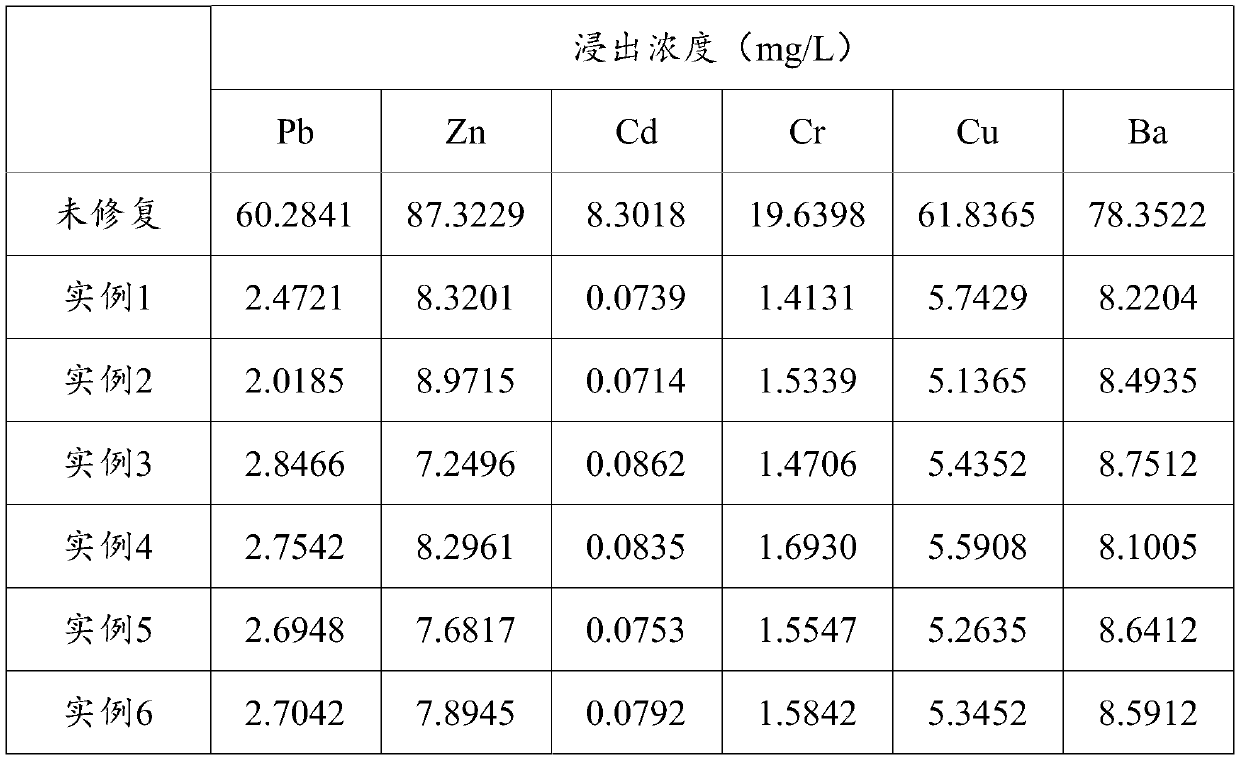

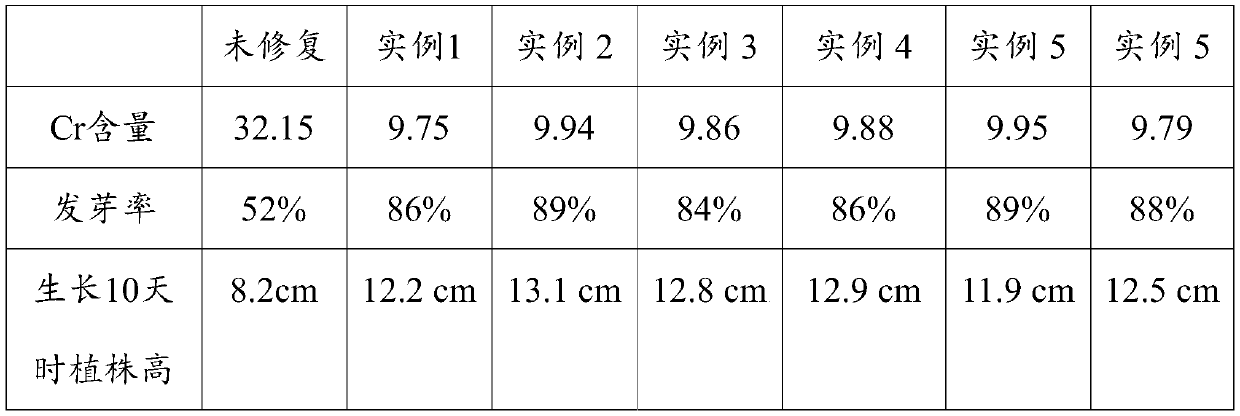

Examples

example 1

[0058] The heavy metal solidifying agent raw material weight composition that this example adopts is:

[0059] 60 parts of peat, 3 parts of Y-type nano molecular sieve, 5 parts of Bacillus subtilis, 3 parts of Acetobacter aceti, 5 parts of Bacillus licheniformis, 3 parts of Clostridium pasteurianus.

[0060] Among them, due to the wide range of heavy metal-contaminated soils used, the heavy metal curing agent requires a large amount. Therefore, this example has processed and packaged the heavy metal curing agent, which specifically includes the following steps:

[0061] Step 1. prepare raw materials by weight;

[0062] Step 2. The peat is sterilized by cobalt 60 radiation, and the radiation dose is 1.0kGy;

[0063] uniformly mixing the sterilized peat with Bacillus subtilis, Acetobacter aceti, Bacillus licheniformis and Clostridium pasteuriani, packaging the mixture to obtain the first package;

[0064] Step 3. packaging the Y-type nano molecular sieve separately to obtain t...

example 2

[0072] The heavy metal solidifying agent raw material weight composition that this example adopts is:

[0073] 50 parts of peat, 5 parts of Y-type nano molecular sieve, 1 part of Bacillus subtilis, 5 parts of Acetobacter aceti, 10 parts of Bacillus licheniformis, 1 part of Clostridium pasteuriani.

[0074] Among them, due to the wide range of heavy metal-contaminated soils used, the heavy metal curing agent requires a large amount. Therefore, this example has processed and packaged the heavy metal curing agent, which specifically includes the following steps:

[0075] Step A. prepare raw materials by weight;

[0076] Step 2. The peat is sterilized by cobalt 60 radiation, and the radiation dose is 18kGy;

[0077] uniformly mixing the sterilized peat with Bacillus subtilis, Acetobacter aceti, Bacillus licheniformis and Clostridium pasteuriani, packaging the mixture to obtain the first package;

[0078] Step 3. packaging the Y-type nano molecular sieve separately to obtain the ...

example 3

[0086] The heavy metal solidifying agent raw material weight composition that this example adopts is:

[0087] 70 parts of peat, 1 part of Y-type nano molecular sieve, 8 parts of Bacillus subtilis, 1 part of Acetobacter aceti, 4 parts of Bacillus licheniformis, 5 parts of Clostridium pasteuriani.

[0088] Among them, due to the wide range of heavy metal-contaminated soils used, the heavy metal curing agent requires a large amount. Therefore, this example has processed and packaged the heavy metal curing agent, which specifically includes the following steps:

[0089] Step A. prepare raw materials by weight;

[0090] Step 2. The peat is sterilized by cobalt 60 radiation, and the radiation dose is 10kGy;

[0091] uniformly mixing the sterilized peat with Bacillus subtilis, Acetobacter aceti, Bacillus licheniformis and Clostridium pasteuriani, packaging the mixture to obtain the first package;

[0092] Step 3. packaging the Y-type nano molecular sieve separately to obtain the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com