Construction method of radial magnetic bearing improved anti-disturbance controller

A construction method and magnetic bearing technology, applied in the direction of bearings, shafts, bearings, shafts, etc., can solve the problems of time-varying interference of magnetic bearing system parameters, failure to consider energy consumption, poor control effects, etc., and achieve strong anti-interference robustness and dynamic and static response performance, easy to measure, and the effect of improving transient response characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

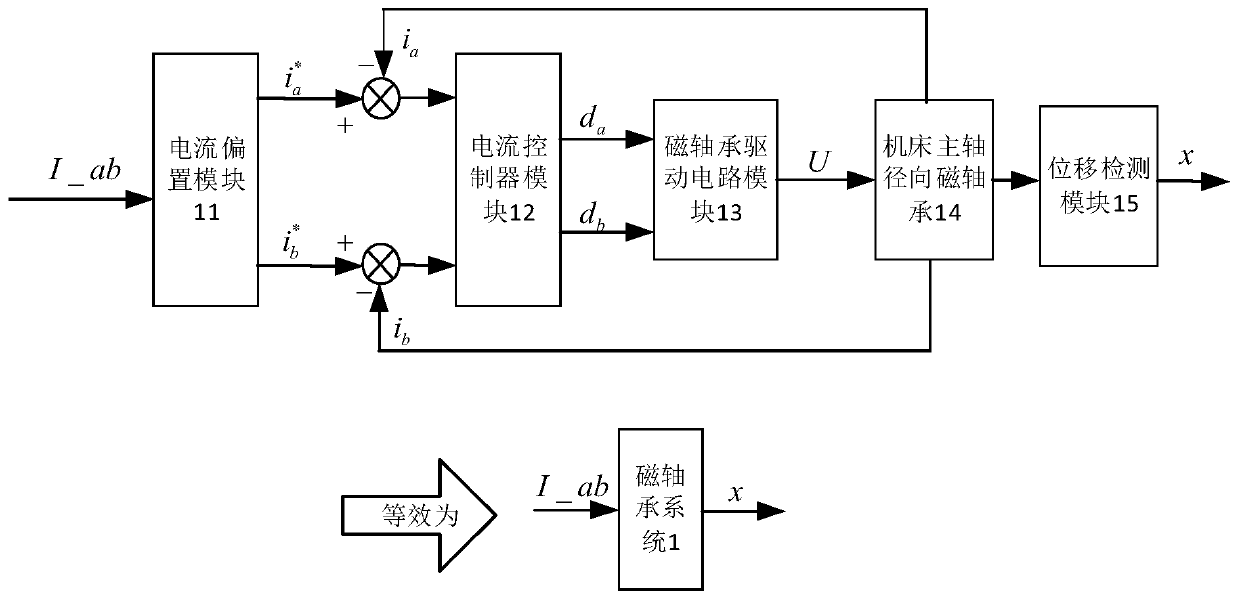

[0019] like figure 1 As shown, the magnetic bearing system 1 is composed of the current bias module 11, the current controller module 12, the magnetic bearing driving circuit module 13, the radial magnetic bearing 14 of the machine tool spindle, and the displacement detection module 15. The magnetic bearing system 1 takes the control current I_ab as Input, with actual displacement x as output. The current bias module 11, the current controller module 12, and the magnetic bearing drive circuit module 13 are sequentially connected in series before the radial magnetic bearing 14 of the machine tool spindle, and the output of the radial magnetic bearing 14 of the machine tool spindle is the actual current i a i b . The current bias module 11 takes the control current I_ab as input, and the output is the reference current of the upper and lower radial windings a and b of the magnetic bearing will refer to the current with actual current i a i b subtraction, the obtained dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com