Electromechanically-integrated gas density relay and system

A gas density and relay technology, applied in the field of electric power, can solve the problems of inaccurate measurement, difficult to meet precise measurement, precise control and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

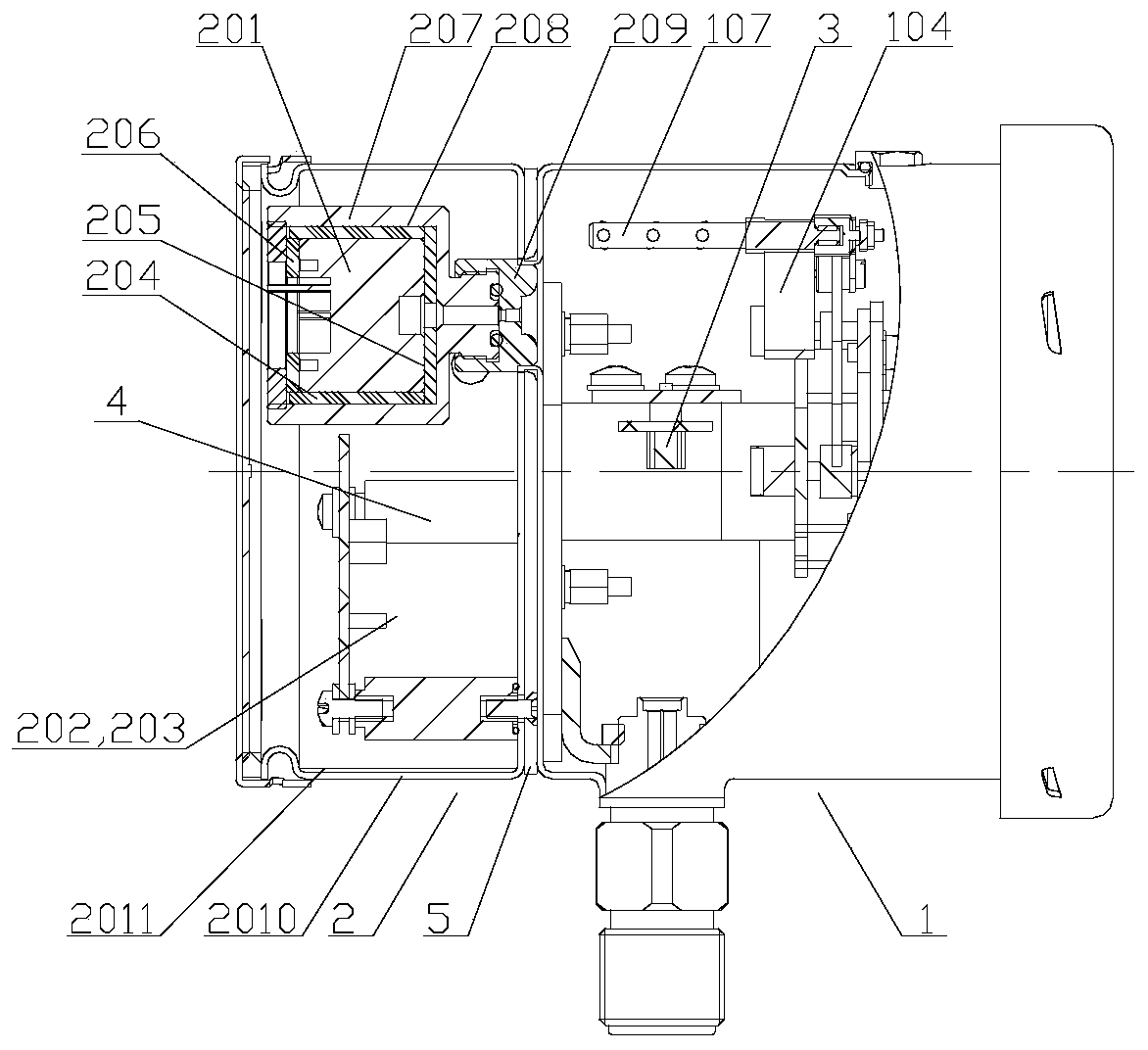

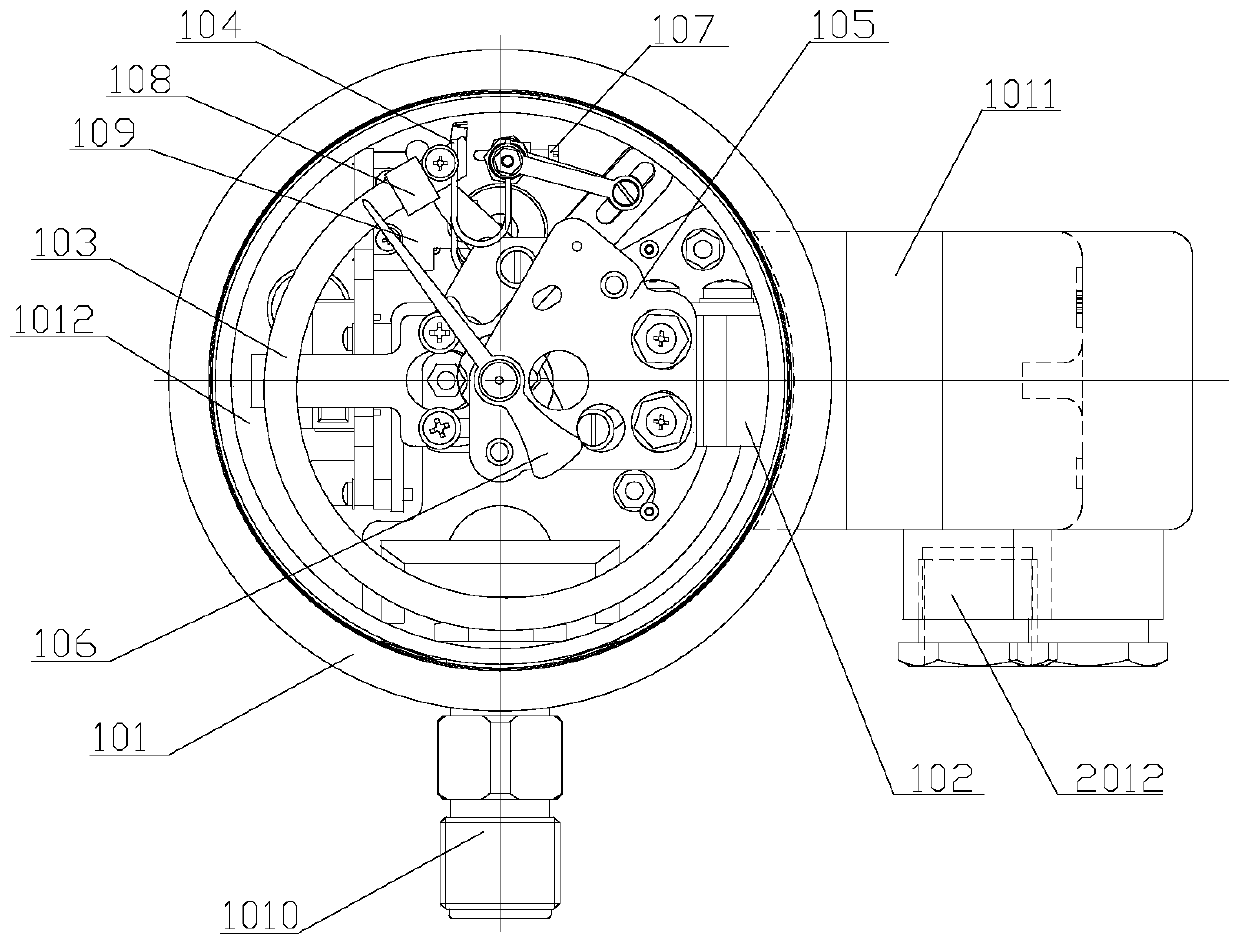

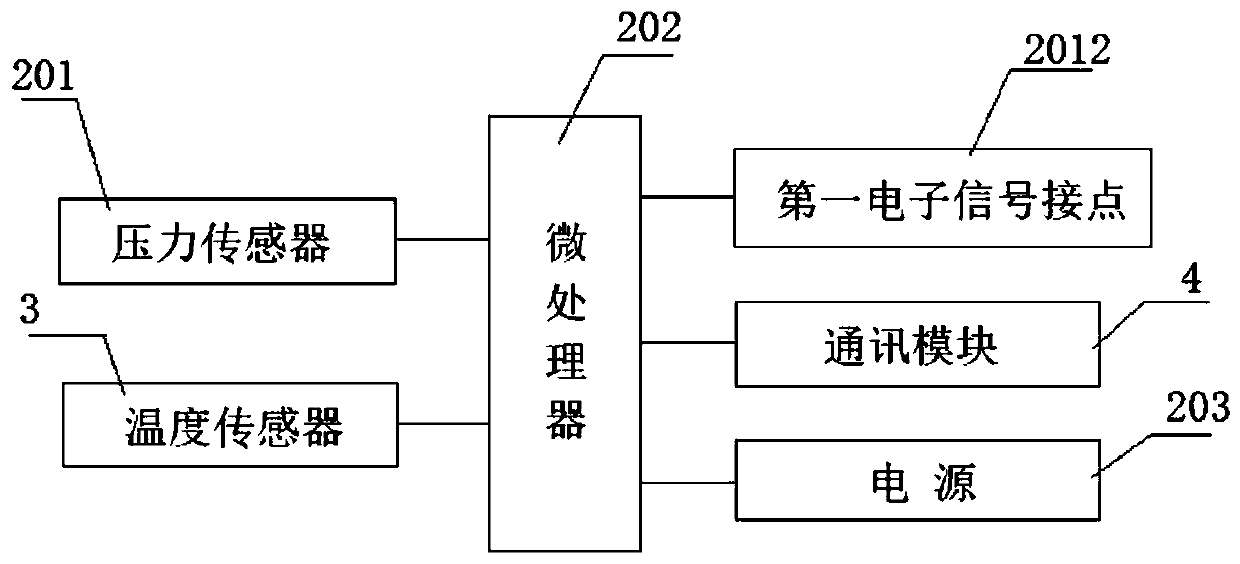

[0104] figure 1 ,with figure 2 It is a schematic structural diagram of a high-performance mechatronics gas density relay used in high-voltage electrical equipment according to an embodiment of the present invention. Such as figure 1 , figure 2 As shown, a mechatronics gas density relay includes a mechanical part 1 and an electronic part 2 relatively independent of the mechanical part; the mechanical part 1 and the electronic part 2 are integrated designs. The mechanical part 1 includes a pressure detector 103, a temperature compensation element 104, and several signal generators 109. The electronic part 2 includes several sensors (pressure sensor 201 and temperature sensor 3) and a microprocessor 202. The microprocessor 202 is respectively connected with several sensors (pressure sensor 201, temperature sensor 3). Collect pressure and temperature signals through several sensors (pressure sensor 201, temperature sensor 3), according to the gas pressure-temperature character...

Embodiment 2

[0134] Figure 4 It is a gas density relay system composed of a high-performance mechatronics gas density relay according to the second embodiment of the present invention. Such as Figure 4 As shown, multiple high-voltage electrical equipment and multiple gas density relays equipped with sulfur hexafluoride gas chambers are connected to the background monitoring terminal through a hub and an IEC61850 protocol converter in sequence. Among them, each gas density relay is respectively arranged on the high-voltage electrical equipment of the corresponding sulfur hexafluoride gas chamber.

[0135] In this embodiment, the background monitoring terminal PC communicates with multiple hubs HUB (HUB1, HUB2,... HUBm) through the hub HUB0. Each hub HUB is connected to a group of gas density relays. For example, hub HUB1 is connected to gas density relays Z11, Z12,...Z1n, and hub HUB2 is connected to gas density relays Z21, Z22,...Z2n,..., hub HUBm is connected to gas density relay Zm1 , Zm...

Embodiment 3

[0138] Figure 5 It is a gas density relay system composed of a high-performance mechatronics gas density relay according to the third embodiment of the present invention. Compared with the second embodiment, this embodiment adds a network switch Gateway, a comprehensive application server Server, and a protocol converter / online monitoring intelligent unit ProC. In this embodiment, the background monitoring terminal PC is connected to two integrated application servers Server1 and Server2 through the network switch Gateway, and the two integrated application servers Server1 and Server2 are connected to multiple protocol converters / online monitoring intelligence through the station control layer A network and B network Unit ProC (ProC1, ProC2,...ProCn) communication, protocol converter / online monitoring intelligent unit ProC communicates with multiple hub HUBs (HUB1, HUB2,...HUBm) through R5485 network. Each hub HUB is connected to a group of gas density relays. For example, hu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com