Preparation method and use method of two-dimensional sheet layer material modified MXene/TiO2 composite material

A technology of composite materials and two-dimensional sheets, applied in chemical instruments and methods, catalyst activation/preparation, chemical/physical processes, etc., can solve problems such as large band gap, difficulty in forming electron-hole pairs, and application limitations , to achieve the effects of simple preparation process, improved visible light response, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

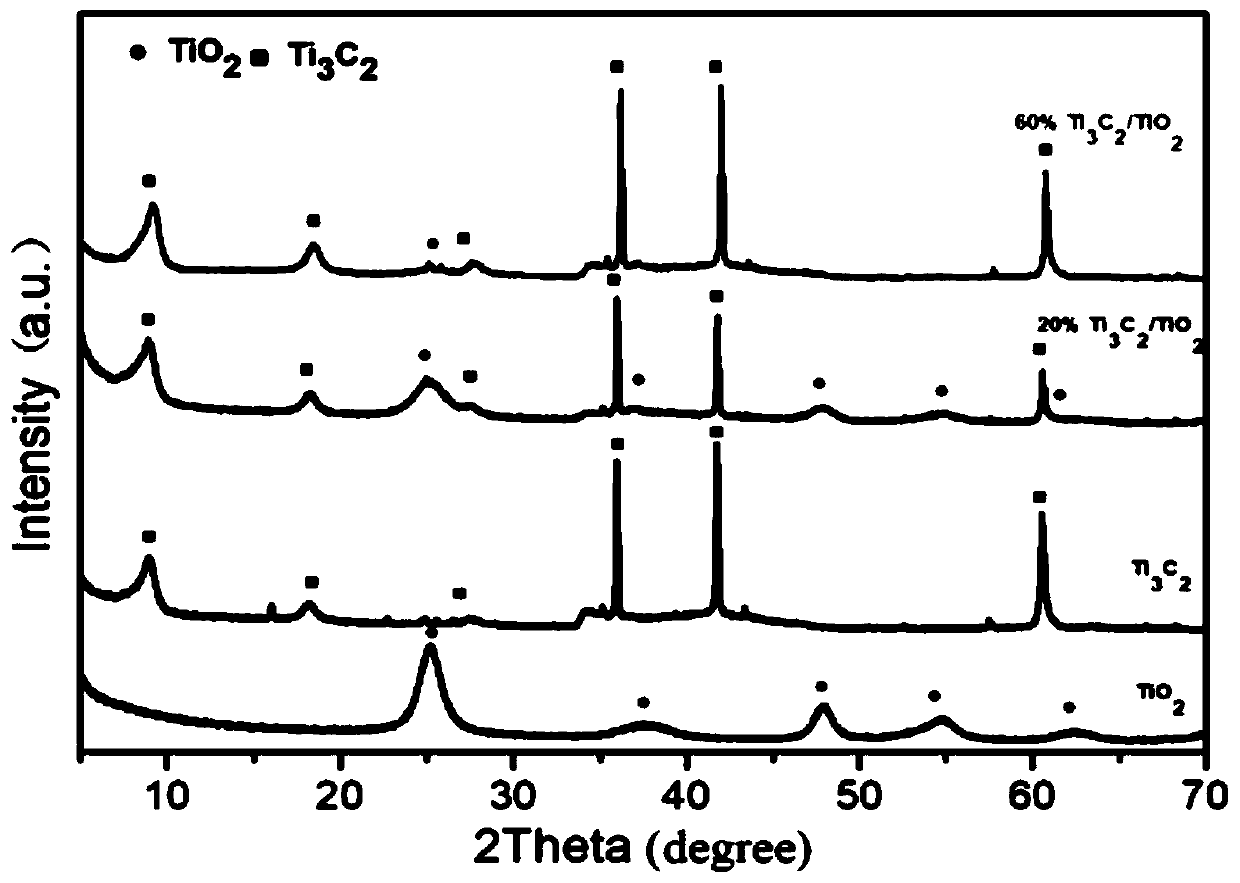

[0026] Measure 10 mL of 49% HF solution and place it in a polytetrafluoroethylene reactor, weigh 1 g of Ti 3 AlC 2 The powder was slowly added into the HF solution, and after being fully stirred, it was put into an oven, and the temperature was raised to 60°C, and the reaction was performed for 24 h. The obtained powder was washed with deionized water to a pH of about 7, and centrifuged with ethanol three times, and finally the powder was dried in a vacuum oven at 60 °C for 24 h to obtain MXene powder.

[0027] Take a certain amount of MXene and a certain amount of tetrabutyl titanate and place them in a polytetrafluoroethylene reactor, add 0.8mL of 49% HF, and then add 30mL of ethanol, sonicate for 40min, pour them into the reactor, and heat them at 80°C After 24 hours of reaction, MXene / TiO was prepared 2 The complex was washed repeatedly with acetone, deionized water and absolute ethanol, and finally dried in an oven at 60 °C.

[0028] Table 1 Sample formula table

[0...

Embodiment 2

[0033] Measure 10 mL of 49% HF solution and place it in a polytetrafluoroethylene reactor, weigh 1 g of Nb 2 AlC (MoTiAlC 3 、Ti 2 AlC, Nb 4 AlC 3 ) powder was slowly added into the HF solution, stirred thoroughly, put it into an oven, raised the temperature to 60°C, and reacted for 24 hours, then washed the obtained sample with deionized water until the pH was about 7, and centrifuged three times with ethanol, and finally The powder was dried in a vacuum oven at 60 °C for 24 h to obtain MXene powder.

[0034] Other steps remain unchanged, the MXene / TiO 2 composite photocatalyst.

Embodiment 3

[0036]Prepare 20 mg / L rhodamine B solution, take 50 mL each time as the reaction solution, add 20 mg powder sample, and keep stirring the reaction solution throughout the process. In order to achieve adsorption-desorption equilibrium, samples were taken after dark adsorption for 30 min in a dark room. Then put it under xenon lamp irradiation (visible light segment), measure 5 mL samples at regular intervals for UV-visible absorbance test, and obtain the concentration of rhodamine B after different reaction times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com