Acid pickling solution for die-casting aluminum alloy passivation technology

A technology of casting aluminum alloy and pickling, which is applied in the field of metal surface treatment, can solve the problems of affecting product quality, short service life, and rapid temperature rise of working fluid, so as to avoid the problem of yellow smoke and improve the overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

[0017] A pickling solution for the pickling solution used in the passivation process of die-casting aluminum alloys. 20wt% oxidant, 0.2-2wt% accelerator and the rest deionized water.

[0018] The configuration method of the pickling solution is: first add a specified amount of water, add fluorine-containing compounds, stir until clear, and then add oxidant after the temperature reaches room temperature, stir until clear and transparent, then add corrosion inhibitor, accelerator, wetting agent in sequence agent, and continue to stir until clear.

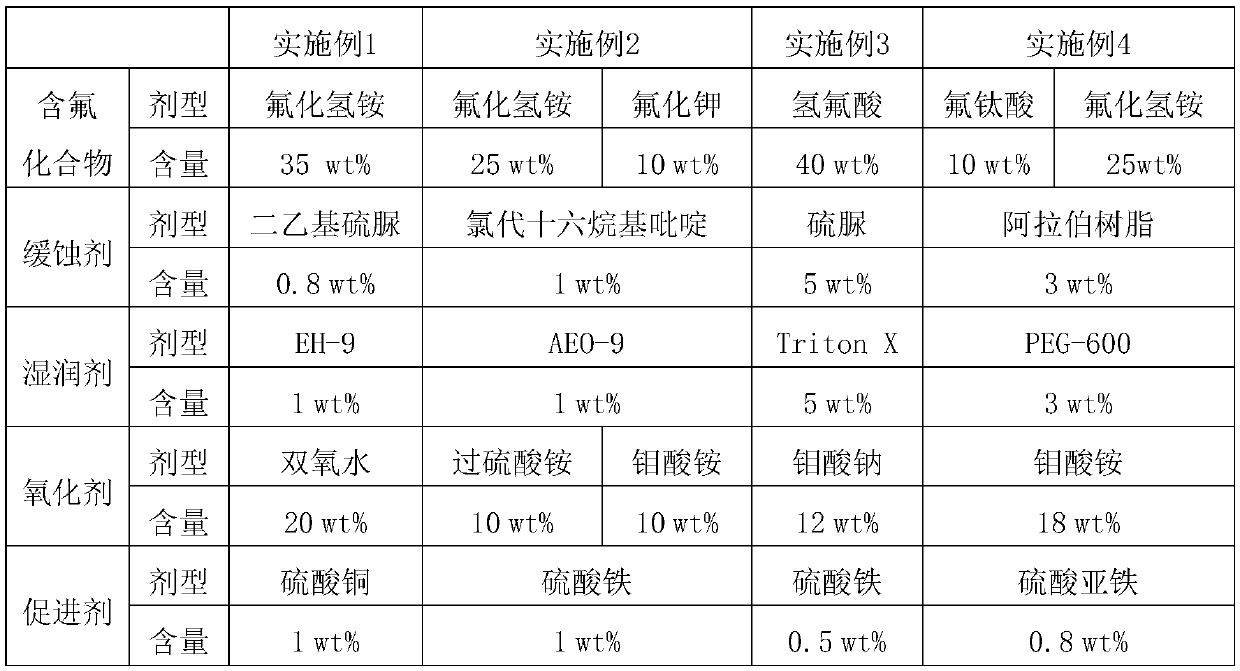

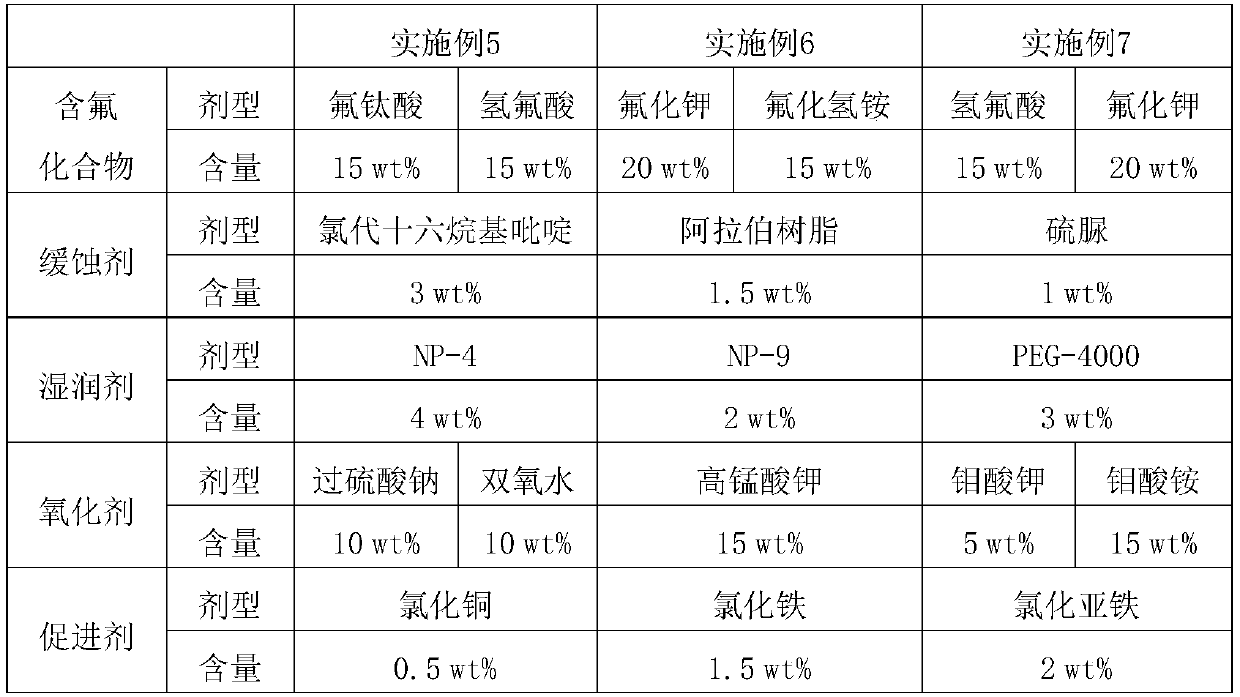

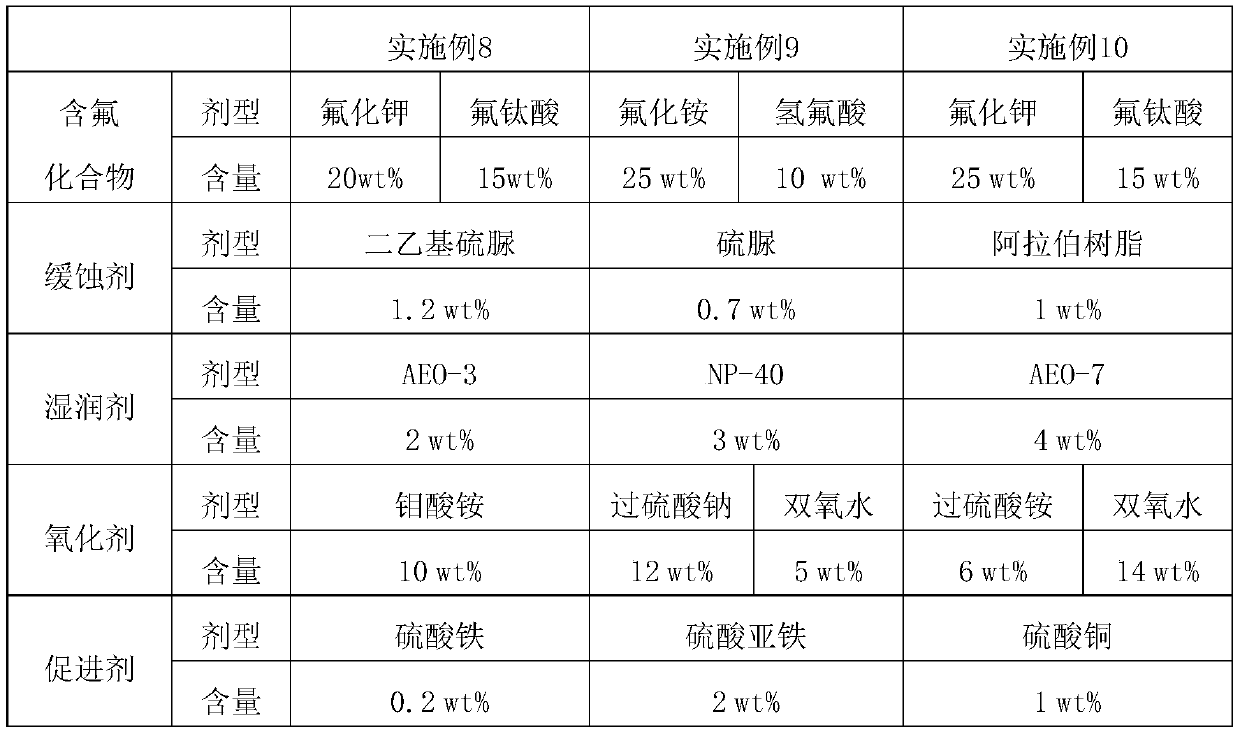

[0019] The detailed formula is as shown in Table 1:

[0020] Table 1:

[0021]

[0022]

[0023]

[0024] Note: The part less than 100wt% in the content is supplemented by deionized water.

[0025] EH-9 is a fatty alcohol isomeric alcohol ether, AEO-3, AEO-7, and AEO-9 are fatty alcohol polyoxyethylene ethers, PEG-600 and PEG-4000 are polyethylene glycols, Triton X , NP-4, NP-9, and NP40 are all alkylphenol polyoxyethylen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com