Photonic crystal fiber sensor for double-channel synchronous detection

A photonic crystal fiber and synchronous detection technology, which is applied in the direction of material analysis, instruments, and measuring devices through optical means, can solve the problems of difficult microfluid filling and low detection efficiency, and achieve simple and feasible detection process and improved sensing performance , high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

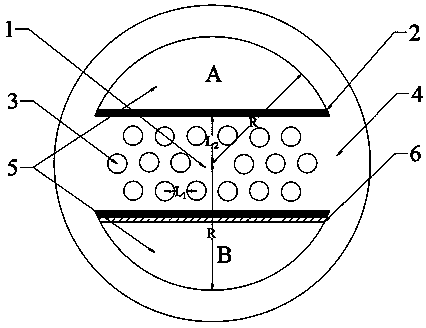

[0020] A photonic crystal fiber sensor with dual-channel synchronous detection, such as figure 1 As shown, it includes a fiber core 1, a gold nano film 2, an air hole 3, a substrate 4, a D-type microfluidic channel 5, and a barium fluoride dielectric layer film 6. Using stable quartz as the substrate material, the refractive index is about 1.45, and air holes are arranged around the center of the substrate. The air holes are arranged in a hexagonal shape with a radius of 0.6 μm, and the distance between adjacent air holes is L 1 2 μm, the missing central air hole part constitutes the core 1. A D-type microfluidic channel 5 is arranged on the base of the upper and lower parts of the air hole, the upper D-type microfluidic channel A is on the upper base of the air hole, and the lower D-type microfluidic channel B is placed on the lower base of the air hole , the radius R of the two D-type microfluidic channels is 8 μm, and the vertical distance L from the center of the optical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com