Polarizer resistant to xenon lamp test as well as preparation method thereof

A technology of polarizer and manufacturing method, which is applied in the directions of weather resistance/light resistance/corrosion resistance, optics, measuring devices, etc., can solve problems such as yellowing, achieve the effect of avoiding yellowing phenomenon and improving the performance of xenon lamp test performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

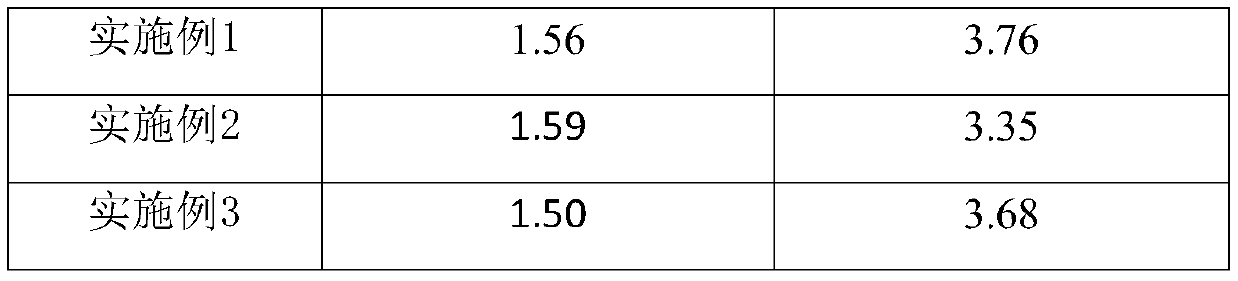

Embodiment 1

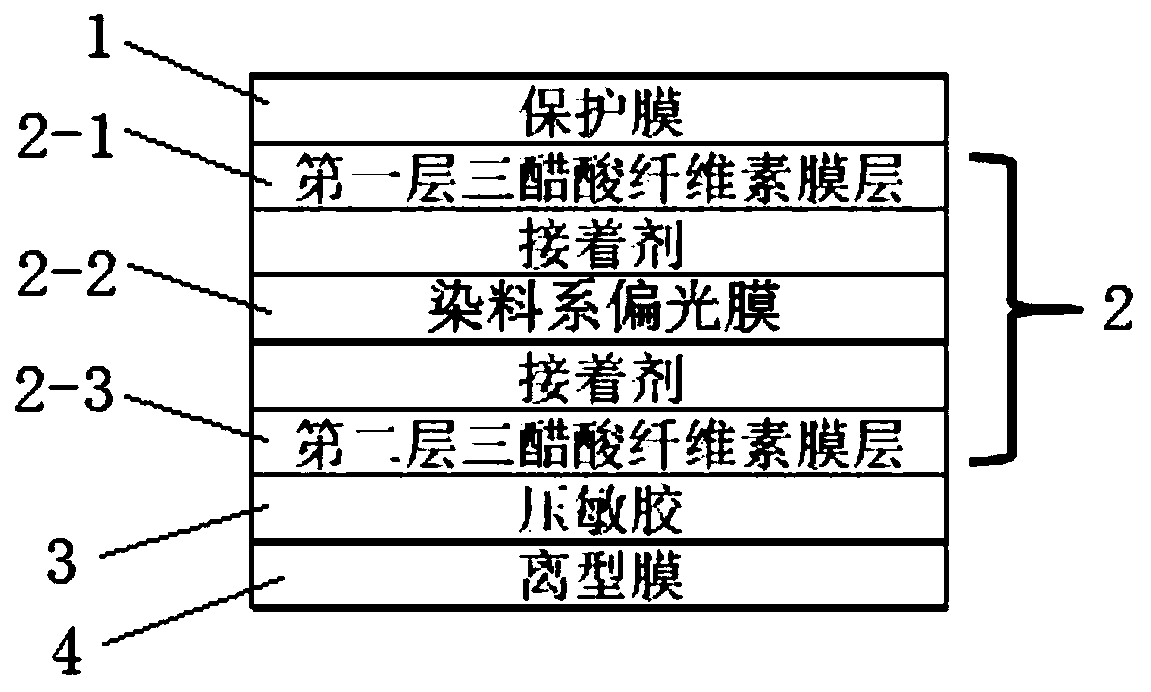

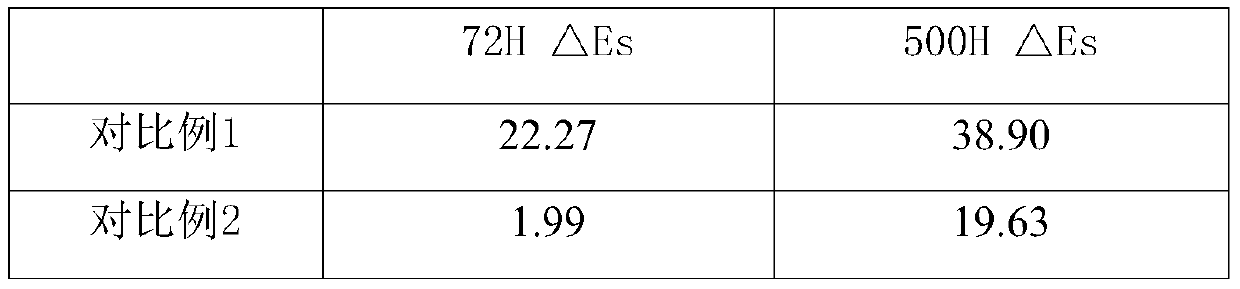

[0034] like figure 1 As shown, a xenon lamp test polarizer includes a protective film 1, a polarizing original plate 2, a pressure-sensitive adhesive layer 3 and a release film 4 bonded together from top to bottom, and the dye-based polarizing original plate 2 consists of The first layer of cellulose triacetate film layer 2-1, the dye-based polarizer 2-2 and the second layer of cellulose triacetate film layer 2-3 bonded together from top to bottom in sequence.

[0035] Wherein, the first cellulose triacetate film layer 2-1 adopts a cellulose triacetate film layer with anti-ultraviolet performance, and the anti-ultraviolet performance means that the transmittance of the full light spectrum at 380nm is 0-5 %.

[0036] The dye-based polarizer 2-2 is formed by swelling, dipping, stretching, color correction and drying of polyvinyl alcohol film, and the dipping liquid is a dichroic dye liquid. The dye-based polarizer 2-2 is bonded with the upper and lower layers of cellulose tria...

Embodiment 2

[0057] A xenon lamp test polarizer, the structure of which is basically the same as that of Example 1, the difference lies in: the hue bs value of the dye-based polarizer original plate 2 is 3.

Embodiment 3

[0059] A xenon lamp test polarizer, the structure of which is basically the same as that of Example 1, the difference lies in: the hue bs value of the dye-based polarizer original plate 2 is -5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com