Novel terahertz temperature-controlled adjustable multi-frequency metamaterial absorber

A terahertz and metamaterial technology, applied in the field of new terahertz temperature-controlled multi-frequency metamaterial absorbers, can solve the problems of complex and different metamaterial absorbers, and achieve stable physical properties and not easy to damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] A novel terahertz temperature-controlled tunable metamaterial wave absorber, the design idea of which includes the following steps:

[0026] Combined with the traditional "sandwich" absorbing structure, replace the original dielectric layer with temperature-controllable InSb material, then sputter the metal plate at the bottom, and prepare the metal unit structure on the upper surface. The specific process is as follows : First, the InSb thin film is prepared by the three-temperature zone method, and then the underlying metal plate is prepared by magnetron sputtering, and the metal unit is prepared by the MEMS metal lift-off process.

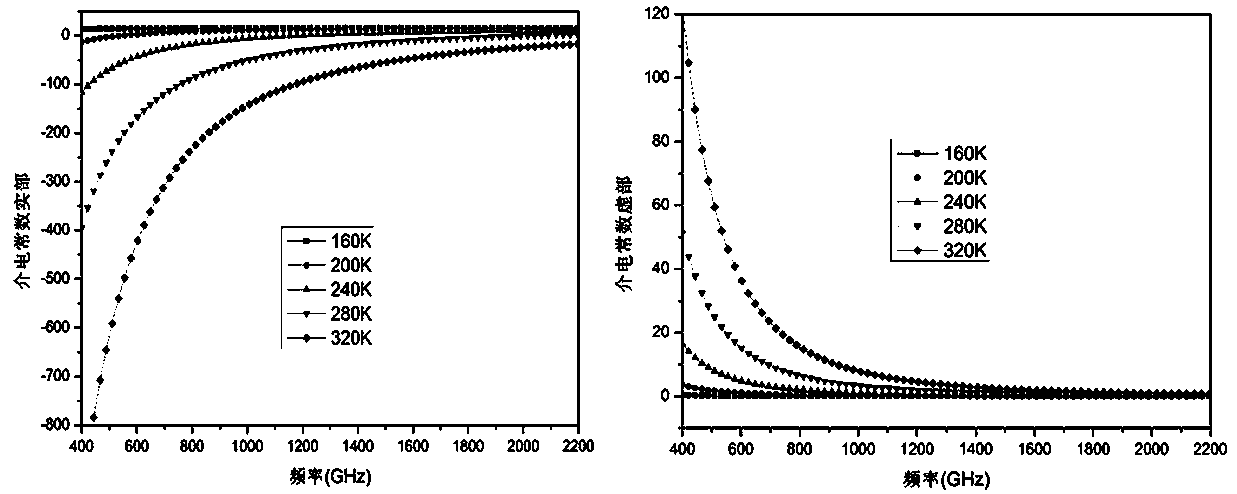

[0027] InSb thin film is a semiconductor thin film with high electron mobility. Vacuum coating technology is used here to prepare InSb thin films on silicon wafers. During the preparation process, inert gases such as nitrogen and helium are used for protection, and the three-temperature zone method is used to control the temperature of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com