Backwashable constructed wetland, and production and operation mode thereof

A constructed wetland and backwashing technology, applied in chemical instruments and methods, aerobic and anaerobic process treatment, special compound water treatment, etc., can solve the problems of limited service life of wetlands, low sewage purification efficiency, and reduced porosity. , to solve the difficulty of backwashing and aeration, achieve good water purification effect, and improve the effect of biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

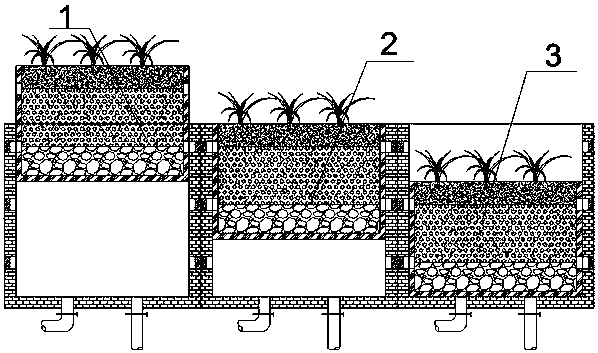

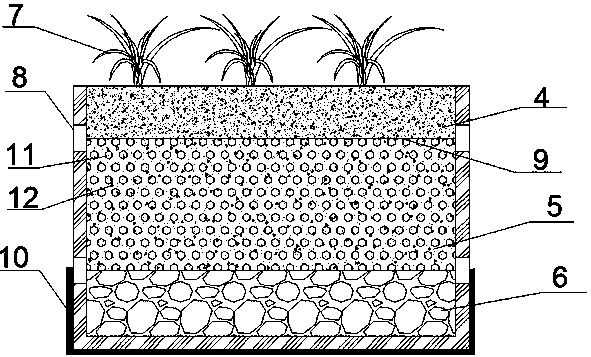

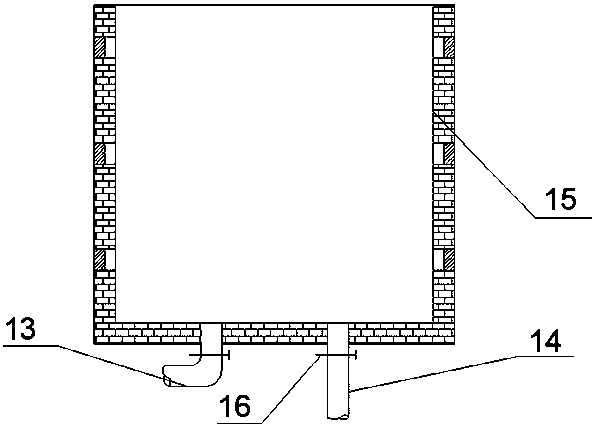

[0052] as attached figure 1 , a backwashable artificial wetland of the present invention is composed of several ecological tanks arranged in sequence, the ecological tanks include a bearing box 15 and a biochemical buoyancy device 8; the bearing box 15 is in the shape of an open empty box, and the bottom is provided with The water outlet 14 and the water outlet 13 are respectively provided with valves 16; the biochemical floater 8 is placed in the bearing box 15, and the buried water depth of the biochemical floater 8 is adjusted by adjusting the water storage capacity in the bearing box 15.

[0053] The size of the biochemical floater 8 is preferably 1.5m×1m×1m (length×width×height), which is a steel bar with a diameter of 5mm as the frame, and a lead wire mesh with an aperture of 5mm as the coverless utensil on the side and bottom; the bottom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com