Reinforcement method, system and technology of oil-containing sludge ultrasonic demulsification

An ultrasonic and demulsification technology, applied in chemical instruments and methods, sludge treatment, petroleum industry, etc., can solve the problems of high sludge treatment cost, large sludge agglomeration, and high energy consumption, so as to improve the effective utilization rate of reagents and save energy. Energy and resource consumption and the effect of improving oil phase quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

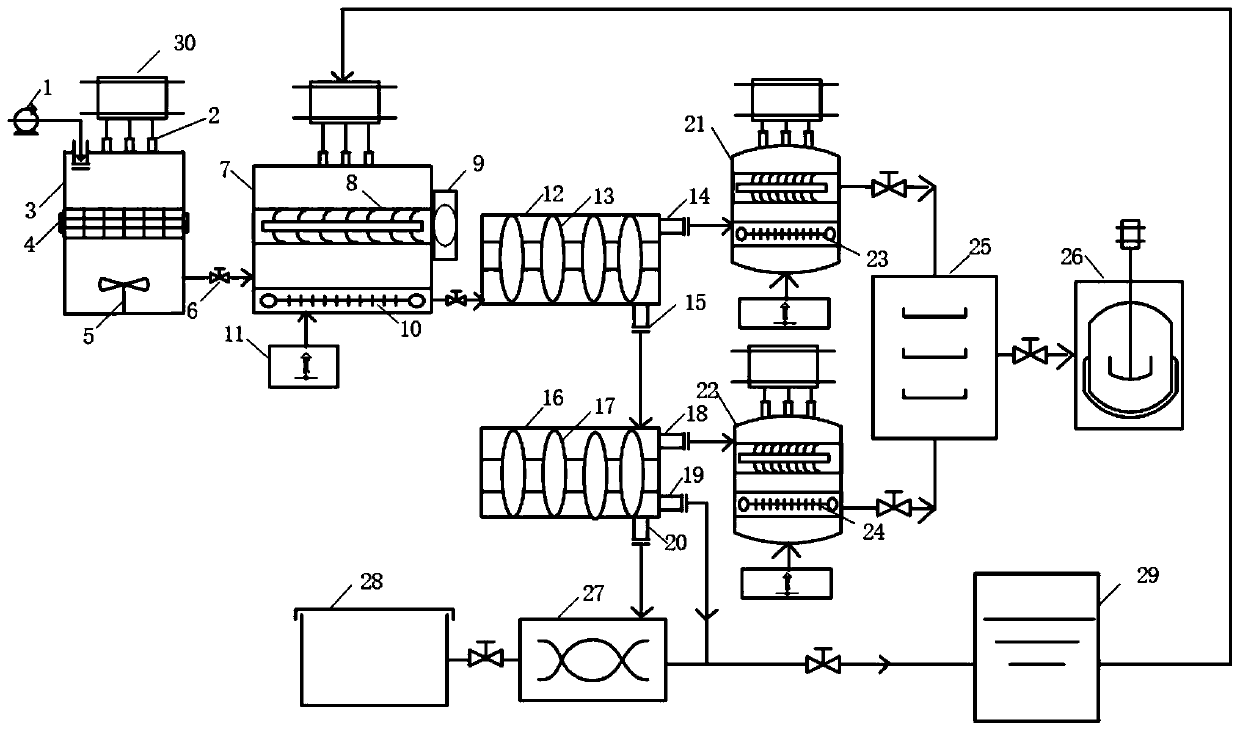

[0072]The enhanced system for ultrasonic demulsification of oily sludge such as figure 1 As shown, the ultrasonic demulsification strengthening method for oily sludge mainly includes the following steps:

[0073] (1) Oil sludge pretreatment. Preliminary screening to remove impurities in the oil sludge, after pumping into the pretreatment pool 3 through the drainage pump 1 set in front of the pretreatment pool 3, adding an appropriate amount of chemical reagents to the drug inlet 2 at the upper end of the pretreatment pool 3 and raising the pretreatment pool 3 The temperature is adjusted by adjusting the agitator 5 at the bottom of the pretreatment tank 3, fully spirally agitating to fluidize the sludge in the treatment tank 3, and the filter screen 4 to filter the solid phase insoluble particles in the pretreatment tank 3.

[0074] (2) Ultrasonic-air flotation demulsification. The uniformly mixed oil sludge treated in the pretreatment tank 3 is pumped into the demulsificatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com