Flame-resistant and antibacterial composite material capable of performing 3D printing as well as preparation method and application thereof

A composite material and 3D printing technology, applied in the direction of additive processing, etc., can solve the problems of no disclosure of inorganic composite flame retardants, no introduction of printing wire preparation process, etc., achieve good mechanical properties and indoor and outdoor usability, prevent continuous burning, Good flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention will be further described below in conjunction with more specific embodiments, but it should be pointed out that the 3D printable flame-retardant antibacterial composite material, preparation method and application of the present invention are not limited to this specific form or procedure. It is obvious to those skilled in the art that the following descriptions can be directly applied to other components or preparation methods of similar composite materials not specified herein even without any adjustment or modification.

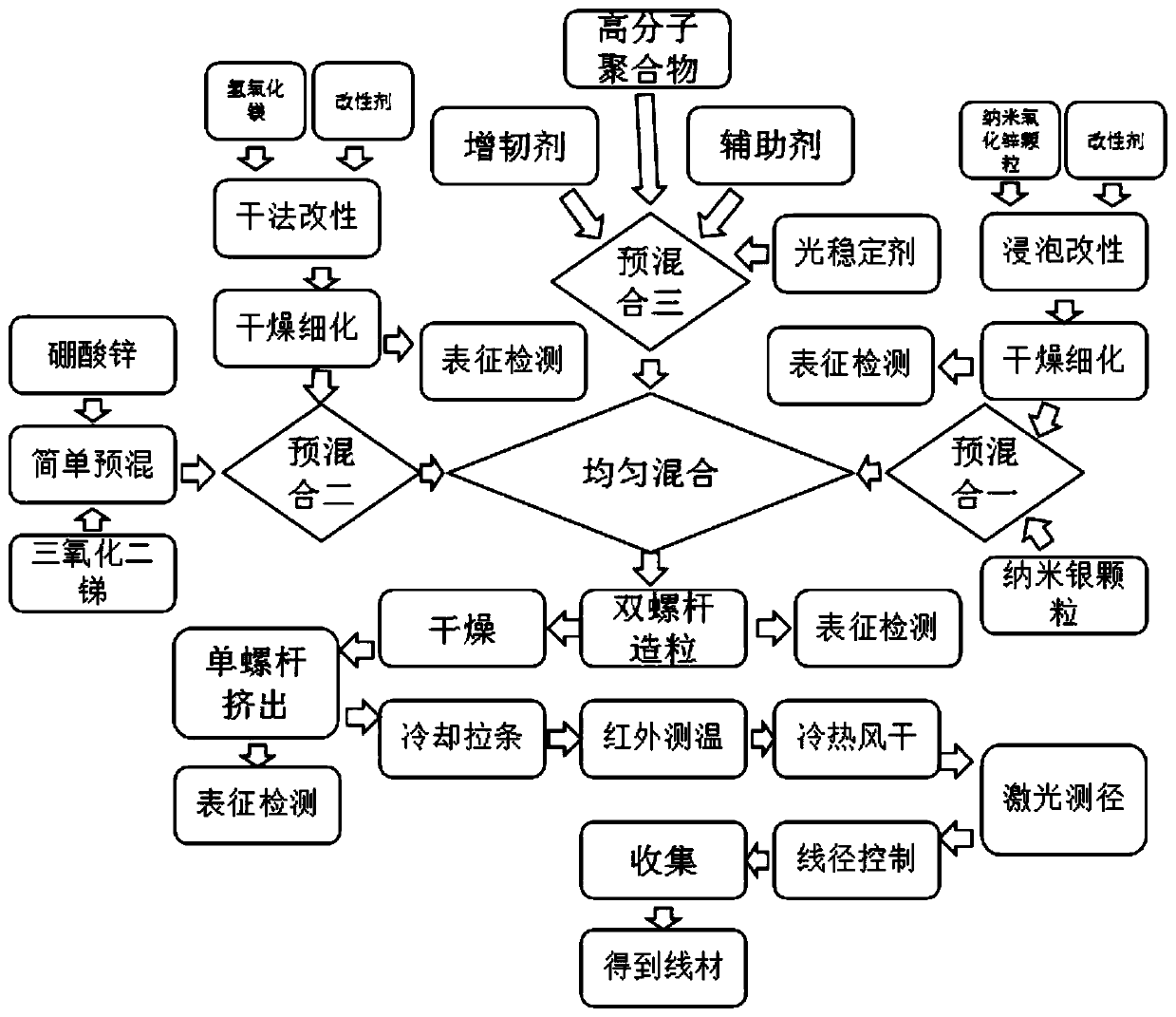

[0036] Such as figure 1 Shown, a kind of 3D printable flame-retardant antibacterial composite material preparation method comprises the following steps:

[0037] (1) Modification:

[0038] First, the dry modification of magnesium hydroxide, using γ-mercaptopropyltrimethoxysilane / magnesium stearate to carry out compound modification on magnesium hydroxide, adding magnesium hydroxide and magnesium stearate to a heatable high-sp...

Embodiment 1

[0049] Modification: First, dry modification of magnesium hydroxide, using γ-mercaptopropyltrimethoxysilane / magnesium stearate to carry out composite modification to magnesium hydroxide, adding magnesium hydroxide and magnesium stearate to the available Stir in a heated high-speed mixing mixer, set the temperature to 45°C, first stir at a stirring speed of 200r / min for 1min, then stir at a stirring speed of 500r / min for 4min; after the stirring is completed, add γ-mercaptopropyltrimethoxysilane , Stir at a stirring speed of 100r / min for 1min, then stir at a stirring speed of 400r / min for 6min, then stir at a stirring speed of 100r / min for 2min, then take it out after natural cooling, grind and refine it through 300 mesh or 300 mesh Screening through a sieve with the above pore size finally obtains γ-mercaptopropyltrimethoxysilane / magnesium stearate composite modified magnesium hydroxide. Secondly, the surface of nano-zinc oxide particles is modified, using ethanol or ethanol-w...

Embodiment 2

[0053] Modification: First, dry modification of magnesium hydroxide, using γ-mercaptopropyltrimethoxysilane / magnesium stearate to carry out composite modification to magnesium hydroxide, adding magnesium hydroxide and magnesium stearate to the available Stir in a heated high-speed mixing mixer, set the temperature to 45°C, first stir at a stirring speed of 200r / min for 1min, then stir at a stirring speed of 500r / min for 4min; after the stirring is completed, add γ-mercaptopropyltrimethoxysilane , Stir at a stirring speed of 100r / min for 1min, then stir at a stirring speed of 400r / min for 6min, then stir at a stirring speed of 100r / min for 2min, then take it out after natural cooling, grind and refine it through 300 mesh or 300 mesh Screening through a sieve with the above pore size finally obtains γ-mercaptopropyltrimethoxysilane / magnesium stearate composite modified magnesium hydroxide. Secondly, the surface of nano-zinc oxide particles is modified, using ethanol or ethanol-w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com