Thermoplastic elastomer-silicone resin composite material and preparation method thereof

A technology of thermoplastic elastomers and composite materials, applied in the field of thermoplastic elastomers, can solve the problems of low efficiency, high cost, and unrecyclable scraps, etc., and achieve the effect of high efficiency and good physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

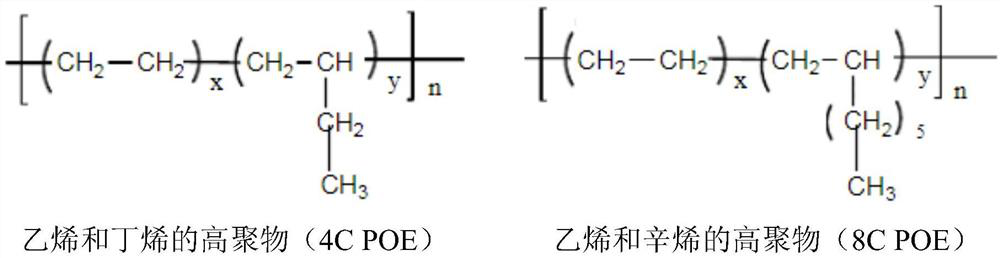

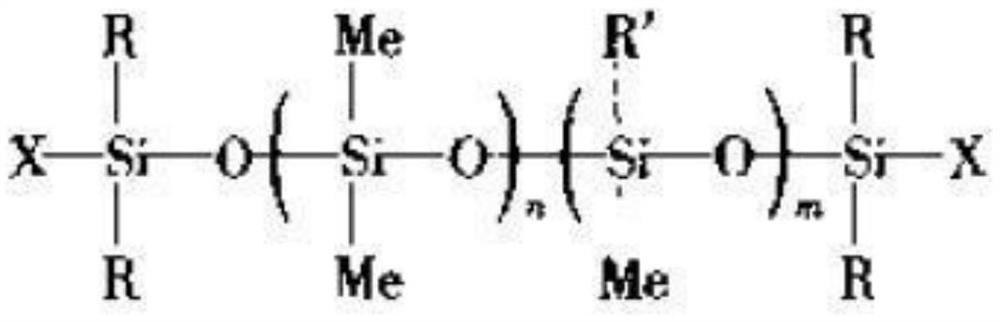

Method used

Image

Examples

Embodiment 1

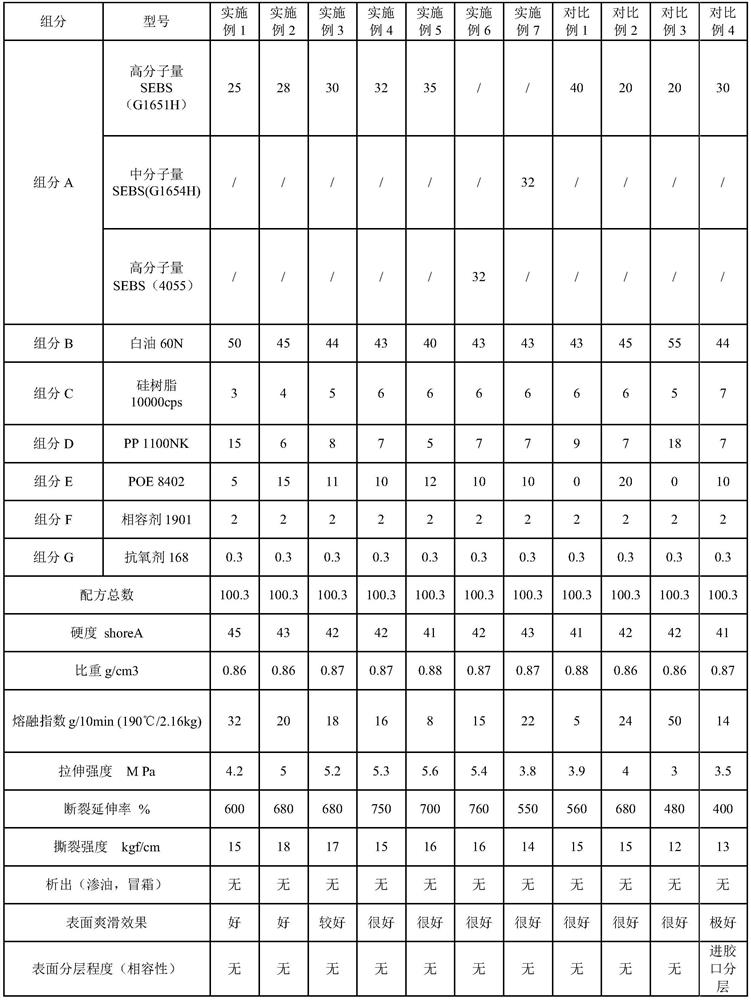

[0044] 25 parts of high molecular weight (weight average about 300,000) SEBS (G1651H), 50 parts of white oil (60N), 3 parts of silicone resin (phenyl vinyl silicone oil, viscosity 10000CPS), PP [copolymerized PP-1100NK, MI: 10 -15g / 10min (230°C / 2.16kg)] 15 parts, POE [8402, its MI: 30g / 10min (190°C / 2.16kg)] 5 parts, antioxidant (phosphorus antioxidant 168) 0.3 part, 2 parts of compatibilizer (1901). Silicone resin (silicone oil) + white oil, mix evenly at a weight ratio of 1:2, add white oil and the aforementioned mixture to SEBS, stir for 3-5 minutes; then add PP, POE and antioxidant, stir for 5-8 minutes, After mixing evenly, melt extruding through a twin-screw extruder at 185-220° C., and then granulate to obtain the thermoplastic elastomer-silicone resin composite material. The specific formula is shown in Table 1.

Embodiment 2

[0046] 28 parts of SEBS (G1651H) with high molecular weight (average weight about 300,000), 45 parts of white oil (60N), 4 parts of silicone resin (phenyl vinyl silicone oil), 6 parts of PP (1100NK), 15 parts of POE (8402) , 0.3 parts of antioxidant (168); 2 parts of compatibilizer (1901). Silicone resin (silicone oil) + white oil, mix evenly at a weight ratio of 1:2, add white oil and the aforementioned mixture to SEBS, stir for 3-5 minutes; then add PP, POE, compatibilizer and antioxidant, stir for 5 minutes -8 minutes, after mixing evenly, melt extruding through a twin-screw extruder at 185-220° C., and then granulate to obtain the thermoplastic elastomer-silicone resin composite material. The specific formula is shown in Table 1.

Embodiment 3

[0048] 30 parts of SEBS (G1651H) with high molecular weight (average weight about 300,000), 44 parts of white oil (60N), 5 parts of silicone resin (phenyl vinyl silicone oil), 8 parts of PP (1100NK), 11 parts of POE (8402) , 0.3 parts of antioxidant (168); 2 parts of compatibilizer (1901). Silicone resin (silicone oil) + white oil, mix evenly at a weight ratio of 1:2, add white oil and the aforementioned mixture to SEBS, stir for 3-5 minutes; then add PP, POE, compatibilizer and antioxidant, stir for 5 minutes -8 minutes, after mixing evenly, melt extruding through a twin-screw extruder at 185-220° C., and then granulate to obtain the thermoplastic elastomer-silicone resin composite material. The specific formula is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| brittleness temperature | aaaaa | aaaaa |

| service temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com