Cathode plate and manufacturing method for manufacturing nickel buckle or cobalt buckle

A technology of cathode plate and nickel buckle, which is applied in the direction of the electrode, etc., can solve the problems of reduced use of the cathode plate, large damage to the insulating layer, and low pass rate of the nickel buckle, and achieves easy peeling, heat resistance stability, and flatness protection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

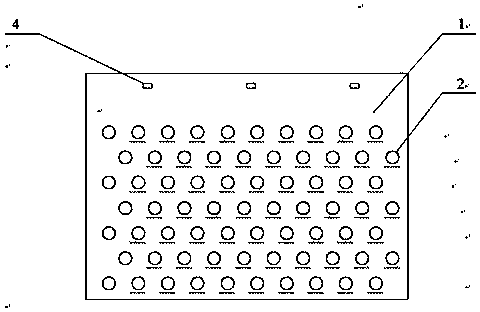

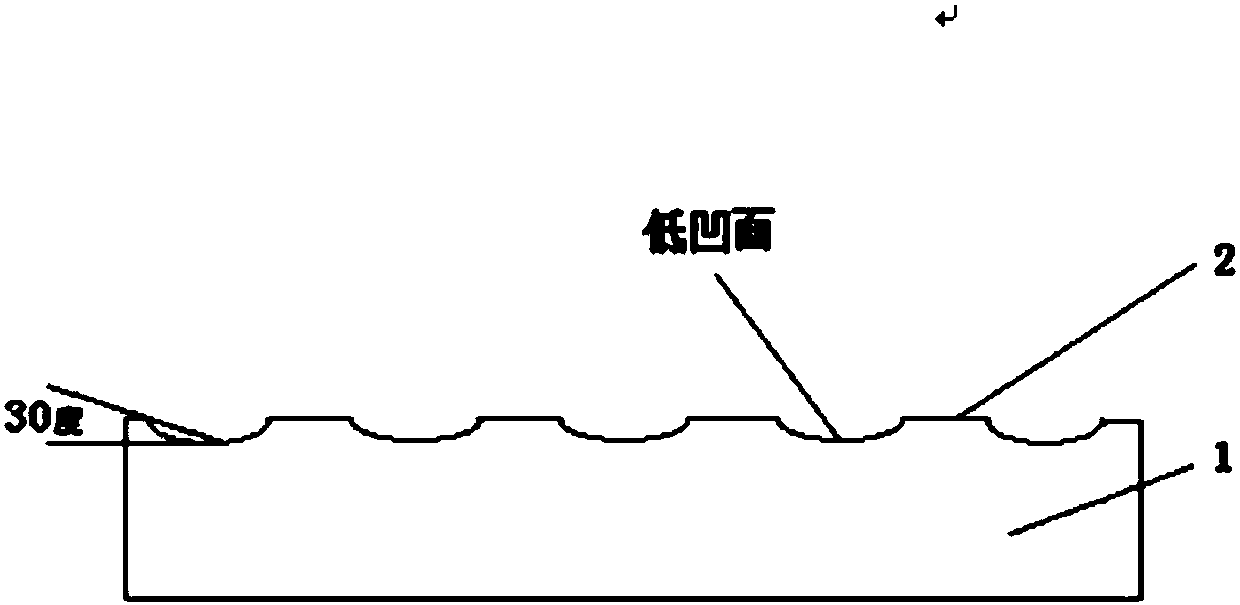

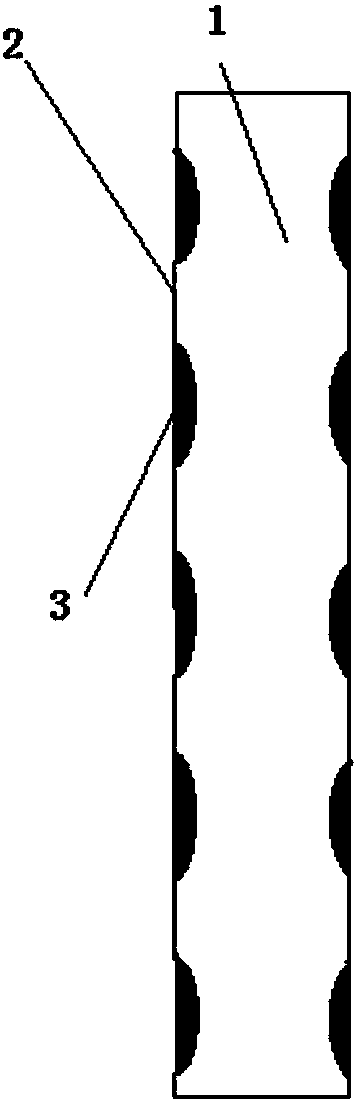

[0029] figure 1 , Use a titanium plate as the metal substrate 1, mark a circular metal surface on the metal substrate, the diameter of the circle can be 8mm-16mm, and 10mm, 13mm or 15mm can be preferred. The circular metal surface is evenly distributed on the metal substrate. The distance between the centers of adjacent circular metal surfaces can be set between 10mm-100mm, preferably between 25mm-30mm. Both sides of the titanium plate are cut and polished to form regular distribution The circular convex platform grown by nickel or cobalt buttons can be distributed in a six-petal quincunx shape. The metal substrate around the circular convex platform is a low concave surface lower than the circular platform and with a certain slope. The slope is preferably 30 degrees. Fill the cut and polished part, that is, the low concave surface, with polyimide-modified silicone resin or phenolic-modified silicone resin until the surface of the metal round table is level with the surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com