Ultra-low resistance precision chip resistor and manufacturing method

A precision chip, resistor technology, used in resistors, resistor manufacturing, resistor parts and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The manufacturing method of the ultra-low resistance precision chip resistor:

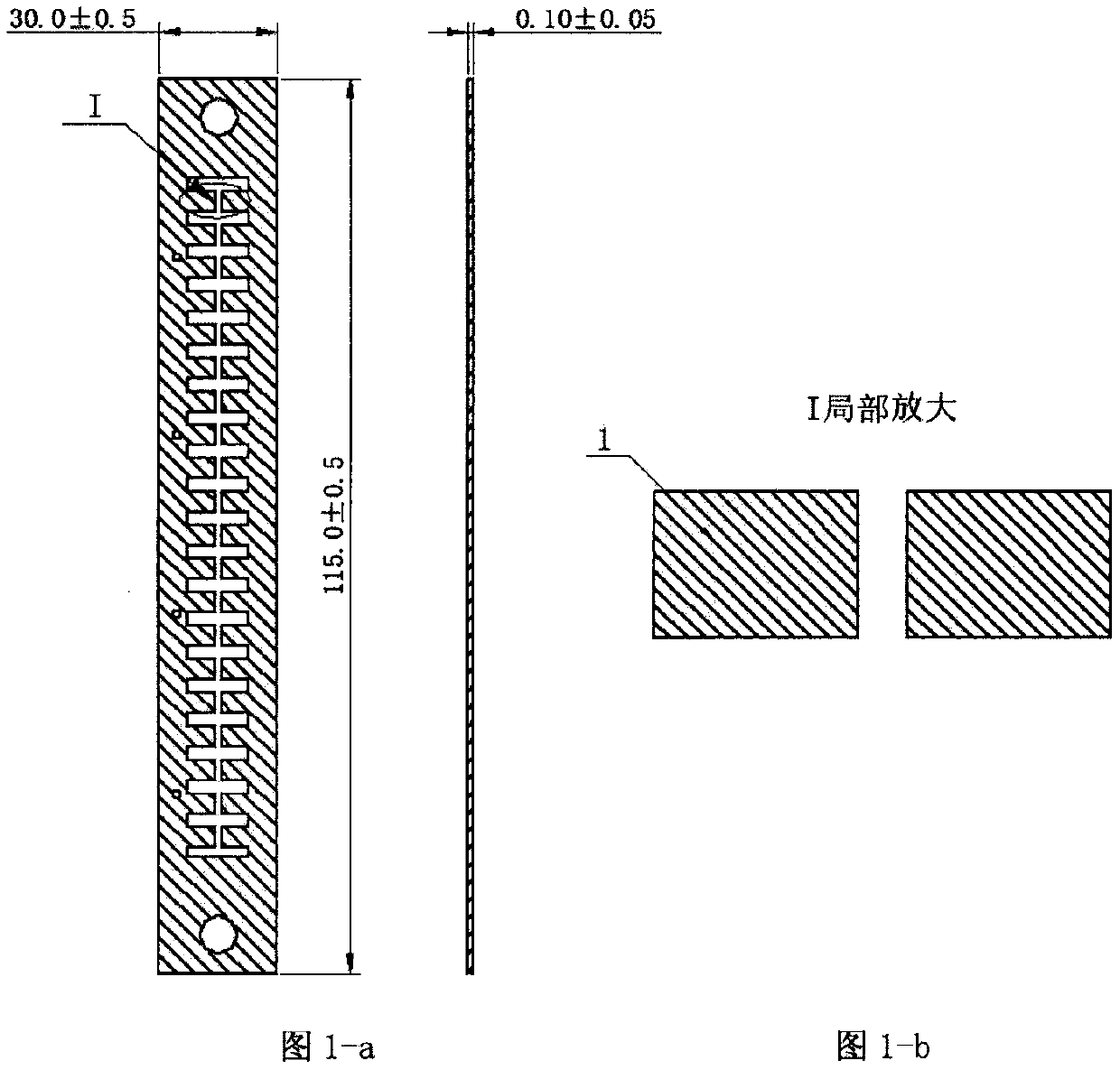

[0033] 1. Make heat dissipation chip strips: use laser cutting technology to cut aluminum strips, cut out Figure 1-a with Figure 1-b The heatsink chip strap shown;

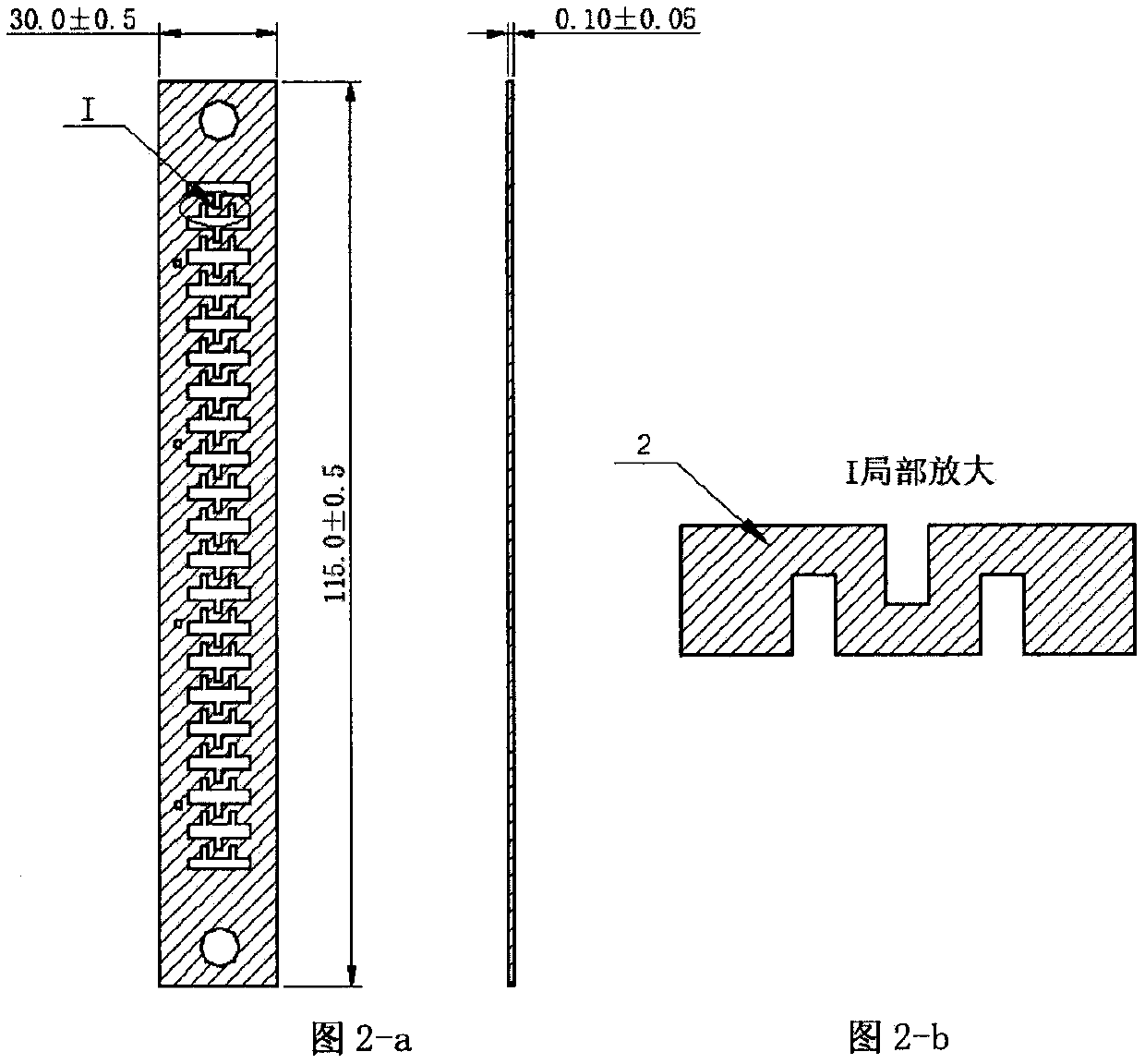

[0034] 2. Making resistance chip strips: use laser cutting technology to cut the alloy strips, and cut out Figure 2-a with Figure 2-b The resistor chip strip shown;

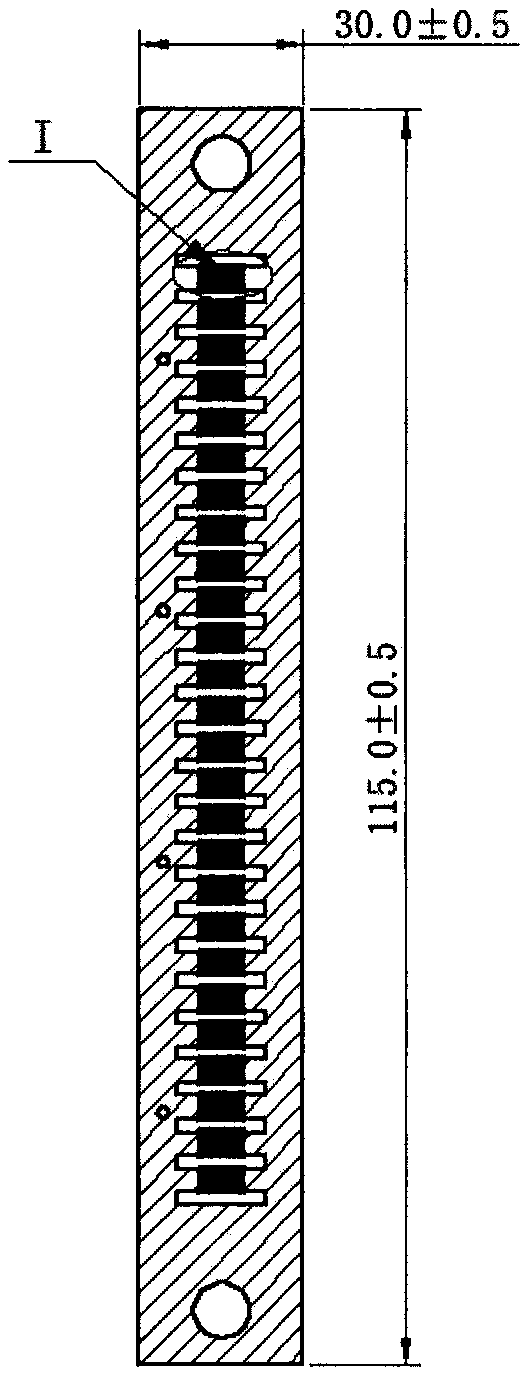

[0035] 3. Make plastic-encapsulated resistance strips: Insulate and bond the resistance chip strips and heat-dissipating chip strips, and put them into the plastic packaging mold for positioning. After the positioning is completed, start the plastic packaging equipment, and plastic seal the Figure 3-a with Figure 3-b The plastic-encapsulated resistance strip shown;

[0036] 4. Make the logo resistance tape: Put the plastic-encapsulated resistance tape into the designated position of the laser marking machine, turn on the laser marking machine, and proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com