UV LED chip of P-type GaN layer and preparation method thereof

A chip, p-type technology, applied in the field of optoelectronics, can solve problems such as the absorption of ultraviolet outgoing light that cannot be well avoided, and achieve the effect of improving external quantum efficiency and luminous power and reducing absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

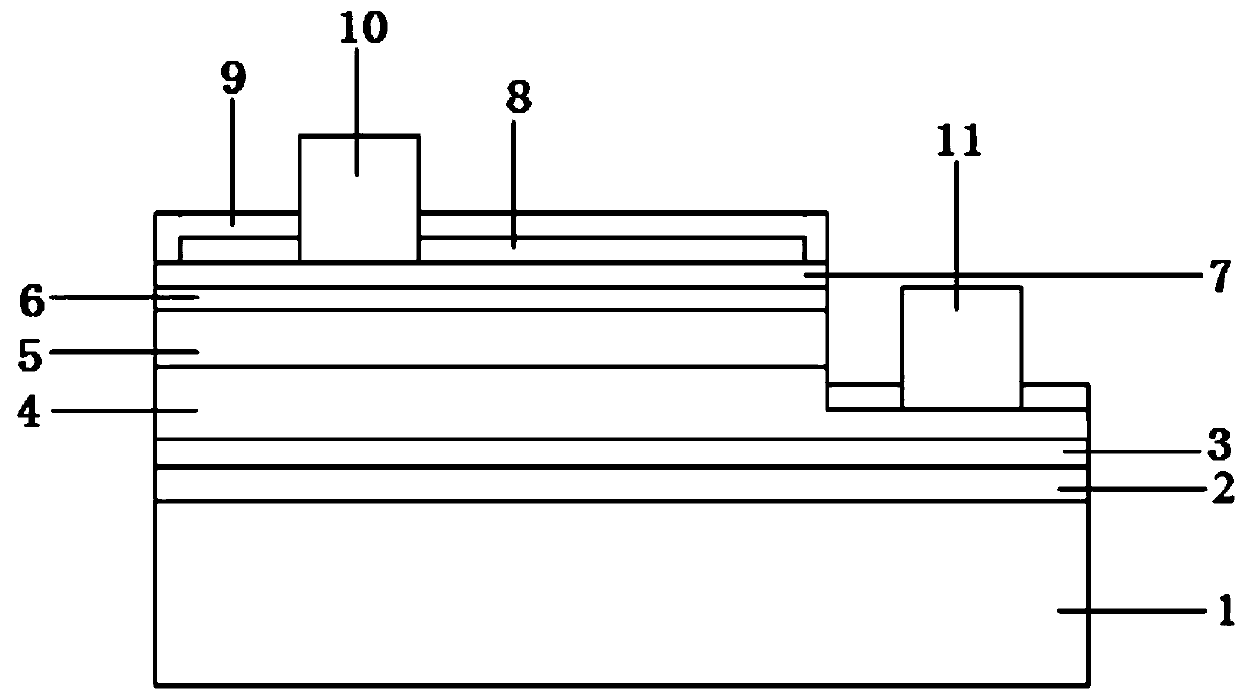

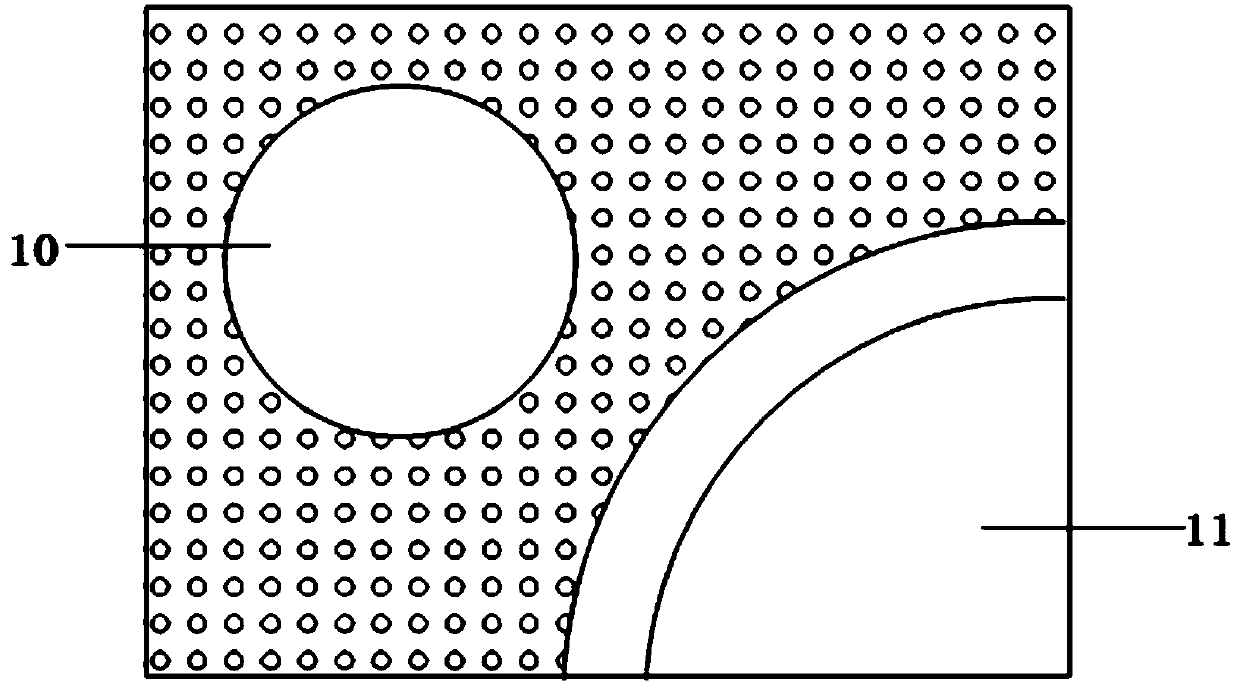

[0042] A UV LED chip with a p-type GaN layer, such as figure 1 As shown, it includes substrate 1, AlN buffer layer 2, non-doped AlGaN buffer layer 3, n-type AlGaN layer 4, quantum well layer 5, electron blocking layer 6, p-type GaN layer 7, A transparent conductive film layer 8 and a passivation layer 9, the transparent conductive film layer 8 is provided with a p-type ohmic electrode 9, the n-type AlGaN layer 4 is provided with an N-type ohmic electrode 11, and the p-type GaN layer 7 is uniformly etched with cylindrical body. The schematic diagram of the structure of the etched cylinder on the p-type GaN layer 7 is as follows figure 2 shown.

[0043] The ratio of the surface area of the cylinder to the surface area of the p-type GaN layer 7 was 30%.

[0044] The diameter of the cross-sectional circle of the cylinders is 3 μm, and the distance between adjacent cylinders is 3 μm.

[0045] The quantum well layer 5 is Al x Ga 1-x N / Al y Ga 1-y N multi-quantum well ac...

Embodiment 2

[0051] According to the UV LED chip described in Embodiment 1, the difference lies in that the p-type GaN layer 7 is uniformly etched with cones.

Embodiment 3

[0053] According to the UV LED chip described in Embodiment 1, the difference is that trapezoids are evenly etched on the p-type GaN layer 7 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com