Resin material for filling teeth and preparation method thereof

A technology of resin material and tooth filling, applied in dental preparations, dentistry, dental prosthesis, etc., can solve the problems of not easy to shrink in volume, caries, easy to wear, etc., achieve good bactericidal effect, not easy in volume, and wide in sterilizing range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

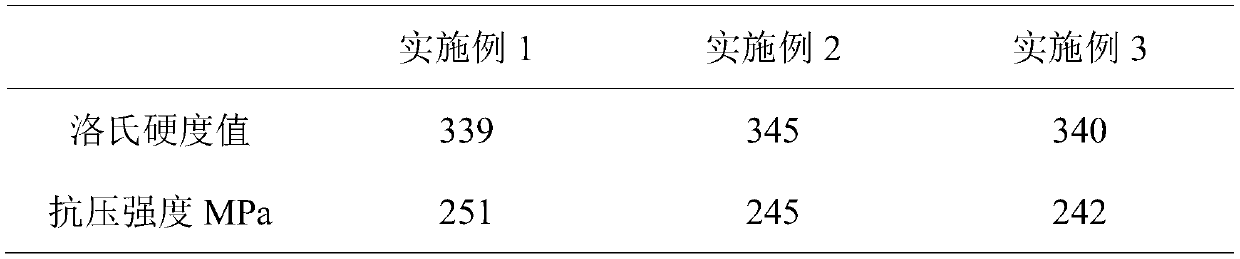

Examples

preparation example Construction

[0029] A kind of preparation method of the resin material for dental filling of the present invention is implemented according to the following specific steps:

[0030] Step 1. Weigh 20-30% of calcium hydroxyphosphate, 10-15% of polymethyl acrylate, 5-10% of triethyl citrate, and 5-10% of diethyl dodecyl phosphonate according to weight , calcium alginate 10-15%, antibacterial agent 2-8%, antioxidant 5-10%, stabilizer 1-3%, double distilled water 20-25%, the sum of the mass percentages of the above components is 100% .

[0031] Step 2. Add calcium hydroxyphosphate, polymethyl acrylate, triethyl citrate, diethyl dodecyl phosphonate and calcium alginate weighed in step 1 into a planetary high-energy ball mill tank, and Ball milling at a speed of 650rmp for 1 to 2 hours, and then ultrasonic vibration for 0.5 to 1 hour to obtain a mixture.

[0032] Step 3. Add the antibacterial agent, stabilizer and antioxidant weighed in step 1 to the mixture obtained in step 2, mix and stir eve...

Embodiment 1

[0039] A kind of preparation method of resin for tooth filling of the present invention, concrete implementation according to the following steps:

[0040] Step 1. Weigh 24% calcium hydroxyphosphate, 10% polymethyl acrylate, 10% triethyl citrate, 5% diethyl dodecyl phosphonate, 11% calcium alginate, nano 3% silver powder, 3% total alkaloid powder of Sophora flavescens, 8% o-cresol, 1% p-methoxyphenol, 25% double distilled water, the sum of the mass percentages of the above components is 100%.

[0041] Step 2. Add calcium hydroxyphosphate, polymethylacrylate, triethyl citrate, diethyl dodecyl phosphonate, calcium alginate and double distilled water weighed in step 1 into the planetary high-energy ball mill tank , ball milled at a speed of 550rmp for 1h, and then ultrasonically oscillated for 0.5h to obtain a mixture.

[0042] Step 3. Add nano-silver powder, total alkaloids of matrine, o-cresol and p-methoxyphenol to the mixture obtained in step 2, and mix and stir evenly at 60...

Embodiment 2

[0044] A kind of preparation method of resin for tooth filling of the present invention, concrete implementation according to the following steps:

[0045] Step 1. Weigh 20% calcium hydroxyphosphate, 15% polymethyl acrylate, 5% triethyl citrate, 5% diethyl dodecyl phosphonate, 15% calcium alginate, and nano 2% silver powder, 6% total alkaloid powder of Sophora flavescens, 10% o-cresol, 2% p-methoxyphenol, 20% double distilled water, the sum of the mass percentages of the above components is 100%.

[0046] Step 2, adding calcium hydroxyphosphate, polymethyl acrylate, triethyl citrate, diethyl dodecyl phosphonate and calcium alginate taken in step 1 in the planetary high-energy ball mill tank, at 650rmp Ball milling at high speed for 1.5 h, and then ultrasonic vibration for 1 h to obtain the mixture.

[0047] Step 3. Add the antibacterial agent, stabilizer and antioxidant weighed in step 1 to the mixture obtained in step 2, mix and stir evenly at 65°C at a stirring rate of 650r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com