Combined desulfurization and denitrification apparatus

A desulfurization, denitrification and denitrification technology, which is applied in the fields of combustion product treatment, combustion method, lighting and heating equipment, etc., can solve the problems of large floor area, high concentration of nitrogen oxide and sulfur dioxide emissions, and complex investment in equipment, so as to ensure Thorough effect of denitrification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

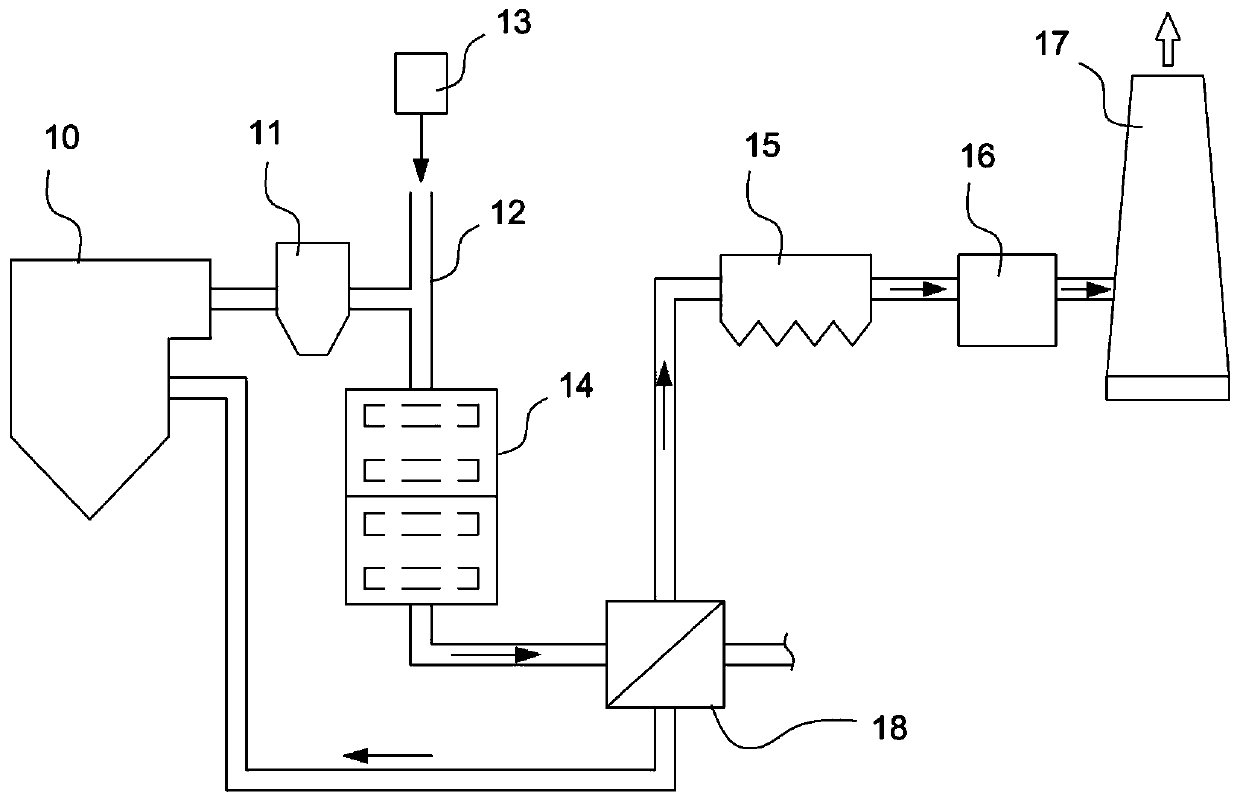

[0025] Such as figure 1 — Figure 4 As shown, the present invention provides a combined desulfurization and denitrification device, comprising:

[0026] A combustion boiler 10, the flue gas produced after coal combustion is discharged from the combustion boiler 10;

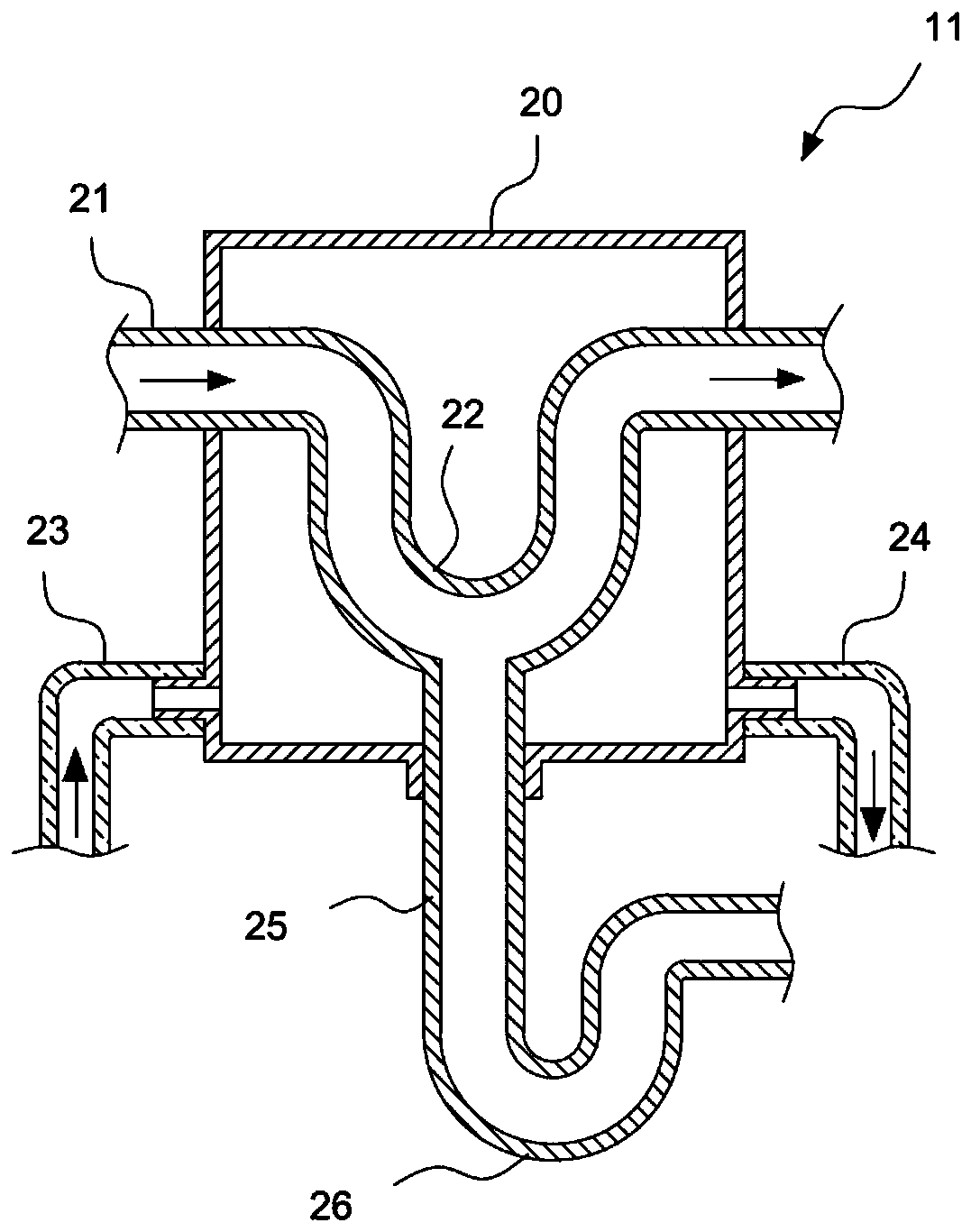

[0027] A flue gas cooling unit 11, which is connected to the combustion boiler 10 through a first pipeline (not shown in the figure) to cool the exhausted flue gas;

[0028] An ammonia gas supply source 13, which stores high-pressure ammonia gas inside;

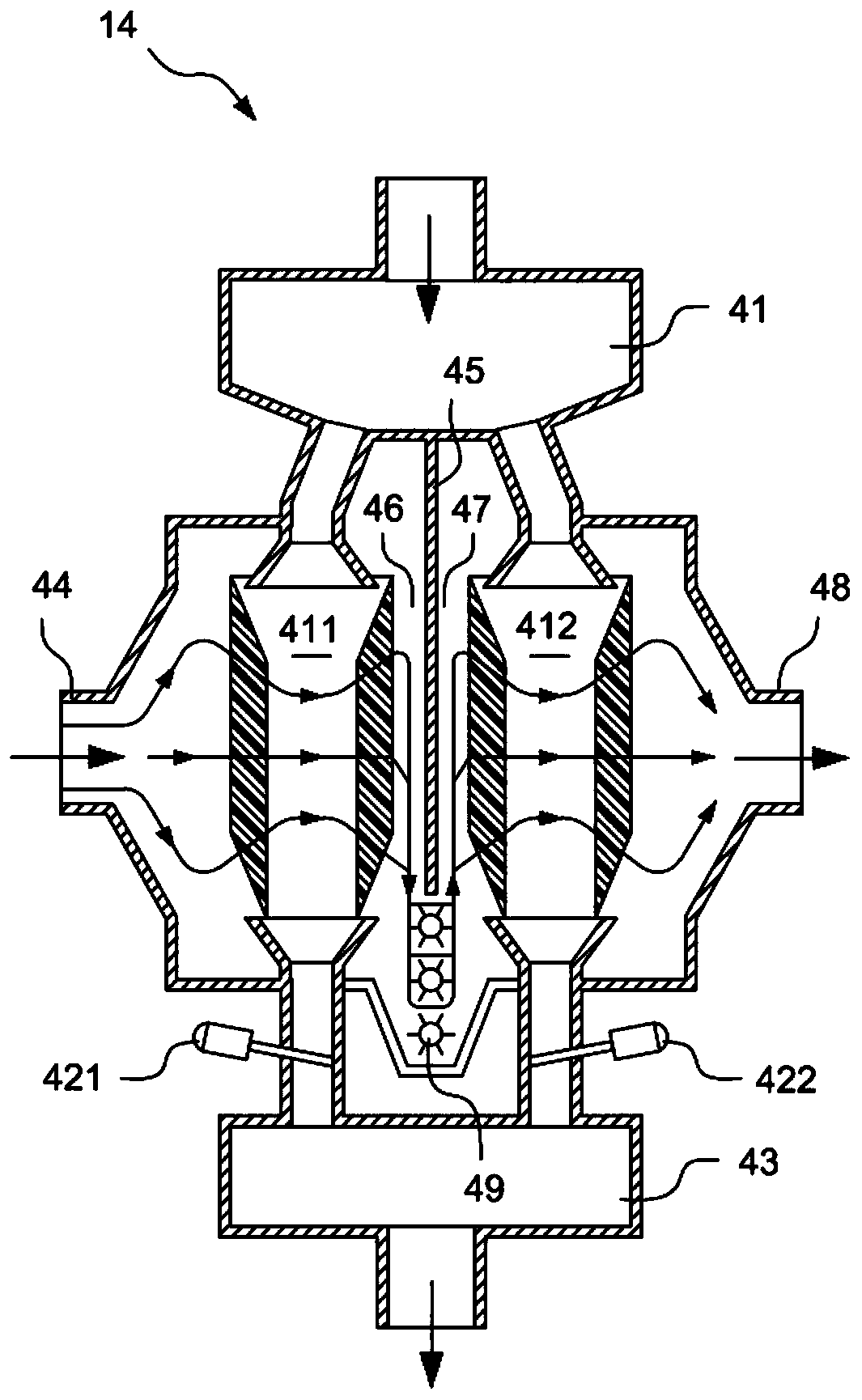

[0029] A denitrification unit 14, which is respectively connected to the flue gas cooling unit 11 and the ammonia gas supply source 13 through a three-way pipeline 12, and the cooled flue gas and ammonia gas are initially mixed in the three-way pipeline 12 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com