Preparation method and application of BiVO4@carbon nanodot composite photocatalytic material

A composite material, carbon nano-dot technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve the effects of excellent degradation of oxytetracycline hydrochloride, simple and convenient preparation process, and great application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

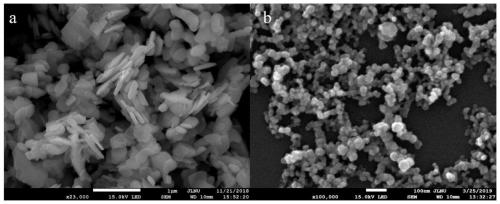

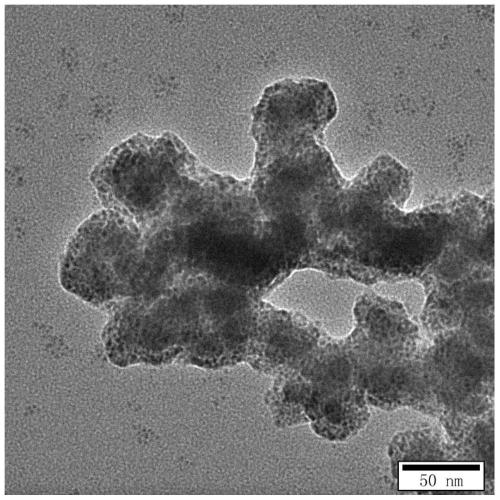

[0024] Dissolve 0.1170 g ammonium metavanadate in 10 mL 2 mol / L sodium hydroxide solution to make mixed solution A, and dissolve 0.4851 g bismuth nitrate pentahydrate and 0.25 g sodium dodecylbenzenesulfonate in 10 mL Prepare mixed solution B in 4 mol / L nitric acid solution, mix mixed solution A and mixed solution B evenly, adjust pH=6 with 2 mol / L sodium hydroxide solution, and obtain BiVO 4 Precursor; 0.01 g of sodium lignosulfonate was added to the prepared BiVO 4 In the precursor, stir to completely dissolve the sodium lignosulfonate, transfer the obtained mixed solution to a reaction kettle for calcination at 200 °C for 8 hours, then centrifugally wash the obtained solid, and dry it to obtain BiVO 4 @Carbon Nanodot Composites.

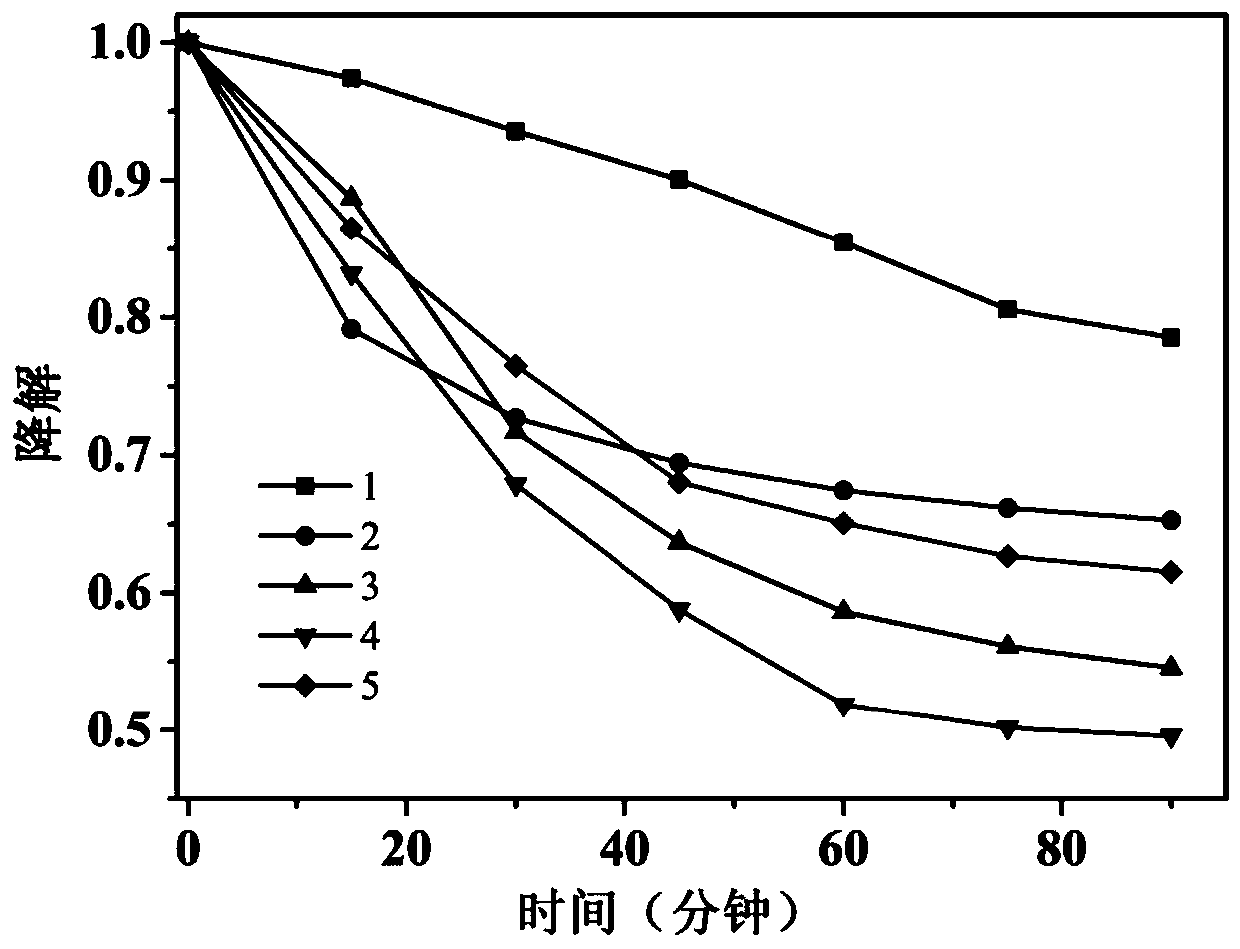

[0025] Photocatalytic degradation test: the obtained BiVO 4 @Carbon nano-dot composite material was tested for photocatalytic degradation in a photochemical reaction instrument, and the BiVO 4 The degradation rate of oxytetracycline hydrochlori...

Embodiment 2

[0027] Dissolve 0.1170 g ammonium metavanadate in 10 mL 2 mol / L sodium hydroxide solution to make mixed solution A, and dissolve 0.4851 g bismuth nitrate pentahydrate and 0.25 g sodium dodecylbenzenesulfonate in 10 mL Prepare mixed solution B in 4mol / L nitric acid solution, mix mixed solution A and mixed solution B evenly, adjust pH=8 with 2mol / L sodium hydroxide solution, and obtain BiVO 4 Precursor; 0.05 g of sodium lignosulfonate was added to the prepared BiVO 4 In the precursor, stir to completely dissolve the sodium lignosulfonate, transfer the obtained mixed solution to a reaction kettle for calcination at 160 °C for 16 hours, then centrifugally wash the obtained solid, and dry it to obtain BiVO 4 @Carbon Nanodot Composites.

[0028] Photocatalytic degradation test: the obtained BiVO 4 @Carbon nano-dot composite material is placed in a photochemical reaction instrument for photocatalytic degradation test, and the BiVO 4 The degradation rate of oxytetracycline hydrochl...

Embodiment 3

[0030] Dissolve 0.1170 g ammonium metavanadate in 10 mL 2 mol / L sodium hydroxide solution to make mixed solution A, and dissolve 0.4851 g bismuth nitrate pentahydrate and 0.25 g sodium dodecylbenzenesulfonate in 10 mL Prepare mixed solution B in 4 mol / L nitric acid solution, mix mixed solution A and mixed solution B evenly, adjust pH=7 with 2 mol / L sodium hydroxide solution, and obtain BiVO 4 Precursor; Add 0.10 g of sodium lignosulfonate to the prepared BiVO 4 In the precursor, stir to completely dissolve the sodium lignosulfonate, transfer the obtained mixed solution to a reaction kettle for calcination at 160 °C for 16 hours, then centrifugally wash the obtained solid, and dry it to obtain BiVO 4 @Carbon Nanodot Composites.

[0031] Photocatalytic degradation test: the prepared BiVO 4 @Carbon nano-dot composite material is placed in a photochemical reaction instrument for photocatalytic degradation test, and the BiVO 4 The degradation rate of oxytetracycline hydrochlorid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com