A kind of manufacturing method of frosted disc for processing tellurium oxide crystal

A manufacturing method and a technology of grinding discs, which are applied in metal processing equipment, abrasive materials, grinding devices, etc., can solve problems such as low product qualification rate, high processing difficulty, and cracks, and achieve cost reduction, grinding efficiency, and processing efficiency. Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

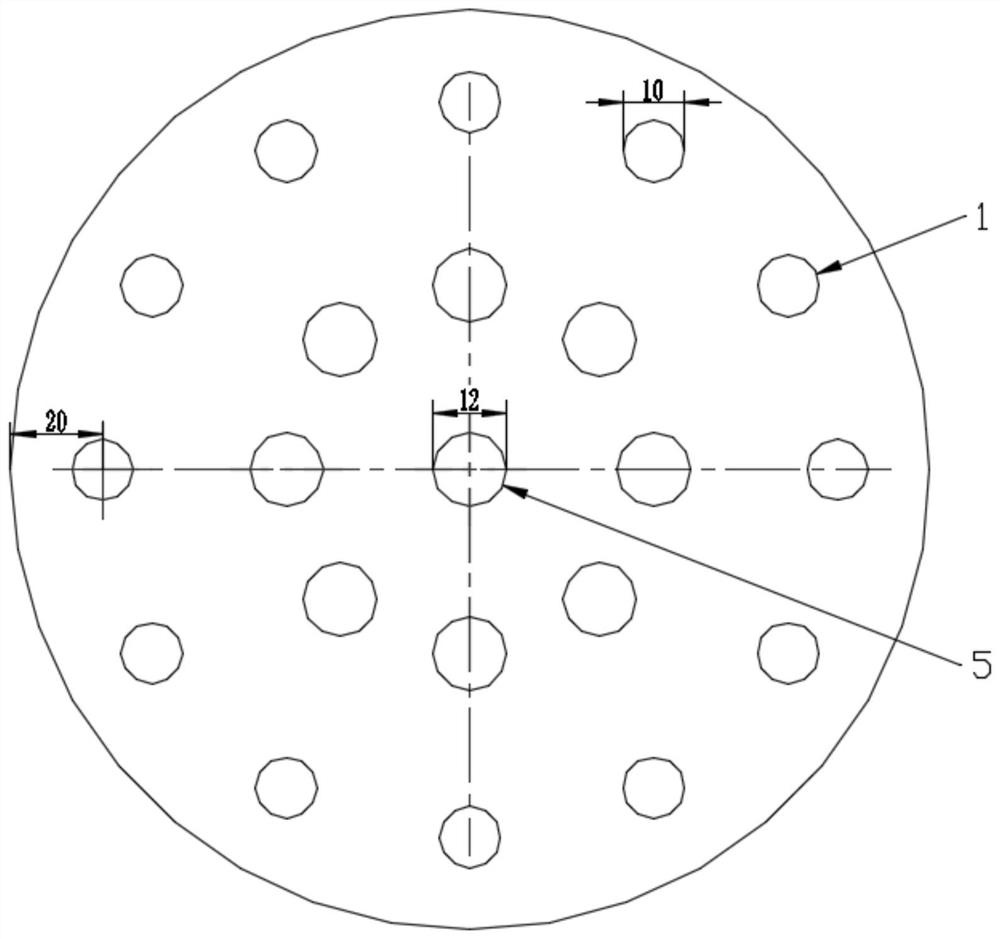

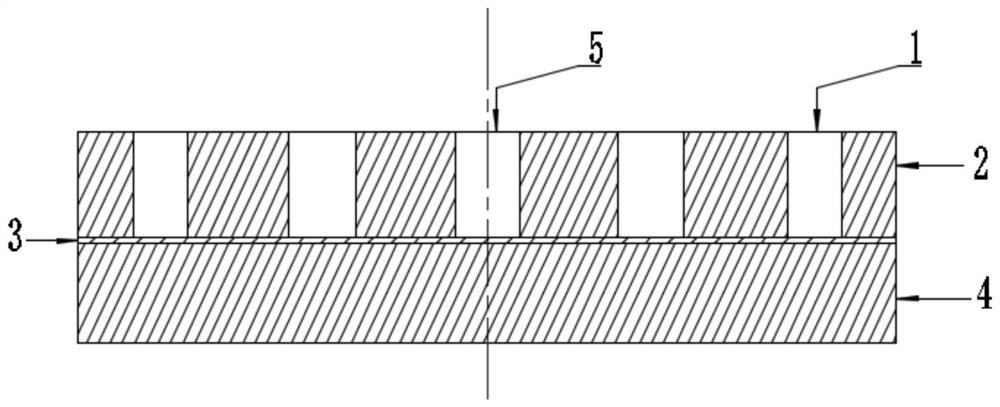

[0023] like Figure 1 to Figure 2 As shown, a grinding disc for processing tellurium oxide crystals includes a ceramic substrate 4 and a grinding sheet 2 fixed on the upper surface of the ceramic substrate 4. The ceramic substrate 4 is disc-shaped and its thickness is 20-25mm, so The thickness of the frosted sheet 2 is 12-15mm, the center of the frosted sheet 2 is provided with a center hole 5, the diameter of the center hole 5 is 12mm, and the frosted sheet 2 is also provided with a number of sets on the same circumference with the center of the center hole 5 as the benchmark. The diameter of the through hole 1 is 10mm. Preferably, the through hole 1 has at least two sets of inner and outer groups, and the distance between the center of the outermost through hole 1 and the edge of the frosted sheet 2 is 20mm.

[0024] The material of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com