Licorice root residue graded porous carbon, preparation method and applications thereof

A licorice slag, graded porous technology, applied in the field of carbon materials, can solve the problems of inability to adapt to industrial production, low specific surface area of carbon materials, and cumbersome pretreatment of precursors, etc., and achieves good cycle stability, high specific surface area, and activation method. efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

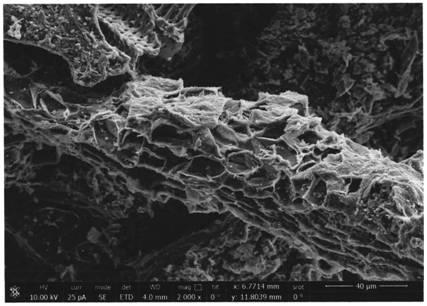

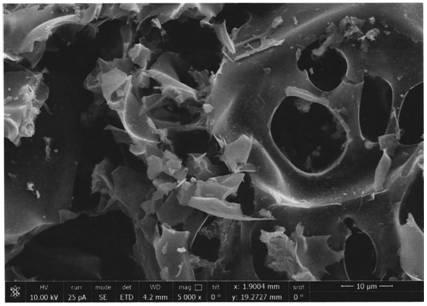

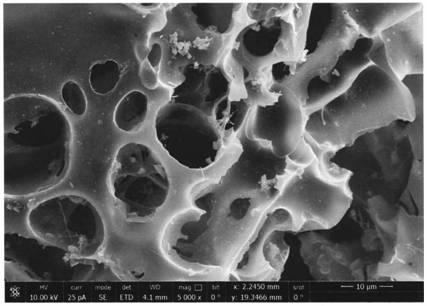

Image

Examples

preparation example Construction

[0030] The invention provides a preparation method of licorice residue-based classified porous carbon, which comprises the following steps:

[0031] Carrying out the first heat treatment on the licorice residue to obtain a pre-carbonized product;

[0032] The pre-carbonized product and lye are mixed, dried, and subjected to a second heat treatment to obtain licorice residue-based hierarchical porous carbon.

[0033] In the present invention, unless otherwise specified, all raw material components are commercially available products well known to those skilled in the art.

[0034] In the present invention, the licorice residue is subjected to the first heat treatment to obtain a pre-carbonized product; in the present invention, before the first heat treatment, the licorice residue is preferably pretreated, and the pretreatment preferably includes washing and drying; the present invention There is no special limitation on the washing and drying, and the washing and drying proce...

Embodiment 1

[0051] After washing and drying the licorice dregs, take 2 g of licorice dregs and cut them into pieces, put them into a porcelain boat, then place the porcelain boat in a tube furnace, and put N 2 Exhaust the air in the tube furnace (and maintain the nitrogen environment), heat it up to 350°C at a heating rate of 5°C / min, keep it warm for 60 minutes, stop heating, and cool to room temperature with the furnace to obtain a pre-carbonized product;

[0052] Put 1 g of the pre-carbonized product into 50 mL of KOH aqueous solution with a concentration of 0.7 mol / L (the mass ratio of the pre-carbonized product to KOH is 1:1), stir evenly, and put it in a blast drying oven at 80 ° C. Dry for 10 hours;

[0053] Grind the above-mentioned dried product, and put the ground product into a porcelain boat, then place the porcelain boat in a tube furnace, and pass N 2 Exhaust the air in the tube furnace (and maintain the nitrogen environment), heat it up to 750°C at a heating rate of 5°C / mi...

Embodiment 2

[0055] The preparation method of the licorice slag-based hierarchical porous carbon refers to Example 1, the only difference is that the mass ratio of the pre-carbonization product to KOH is 1:2, and the licorice slag-based hierarchical porous carbon is denoted as C-2- 750.

PUM

| Property | Measurement | Unit |

|---|---|---|

| micropore | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com