Purple corn procyanidin extracting process

A proanthocyanidin and extraction process technology, applied in the direction of organic chemistry, can solve the problems of proanthocyanidin resource waste, discarding, difficult extraction of corncob proanthocyanidin, etc., and achieve the effect of strong selectivity, short time and high extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] The difference between embodiments 10-13 and embodiment 1 is that the heating temperature in step 1 of S2 is as shown in the table below:

[0082] Example Example 10 Example 11 Example 12 Example 13 temperature / ℃ 50 53 57 60

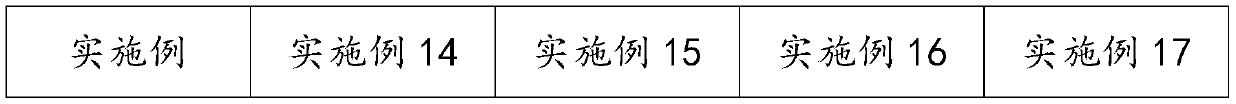

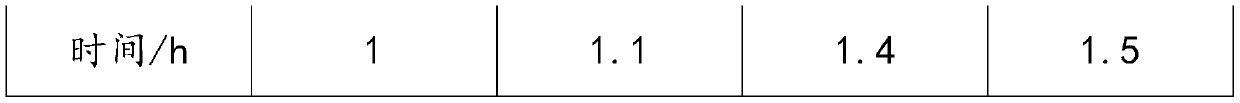

[0083] The difference between embodiment 14-17 and embodiment 1 is that the heat preservation reaction time is shown in the following table in the step 1 of S2:

[0084]

[0085]

[0086] The difference between embodiment 18-21 and embodiment 1 is that the weight ratio of enzyme auxiliary agent and purple corn cob powder is as shown in the following table:

[0087] Example Example 18 Example 19 Example 20 Example 21 weight ratio 0.2 0.3 0.5 0.6

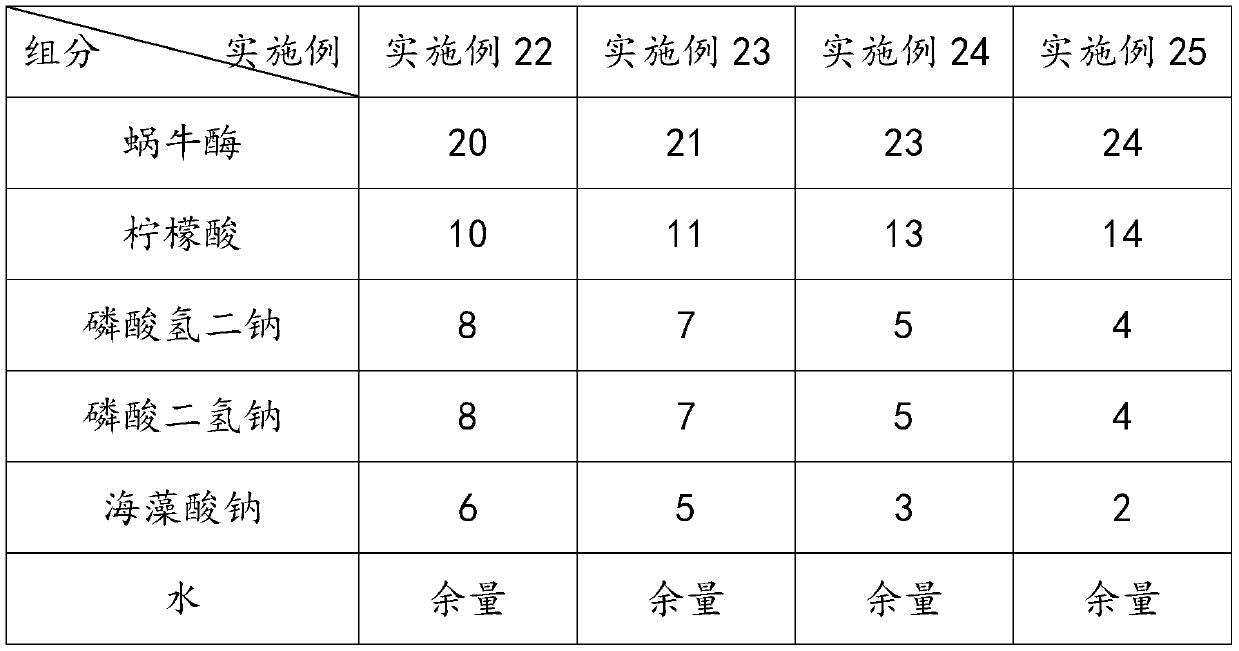

[0088] The difference between Examples 22-25 and Example 1 is that the enzyme auxiliary agent includes the following raw materials in weight percentage:

[0089]

[0090] The difference between Embodiment 26-29 and Embodiment 1 is that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com