Natural gas hydrate inhibitor, natural gas hydrate compounding inhibitor, and preparation methods of natural gas hydrate inhibitor and natural gas hydrate compounding inhibitor

A technology for hydrate inhibitor and natural gas, which is applied in drilling compositions, chemical instruments and methods, gas/liquid distribution and storage, etc., can solve problems such as insufficient inhibition ability, and achieve long-term inhibition and improved inhibition performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

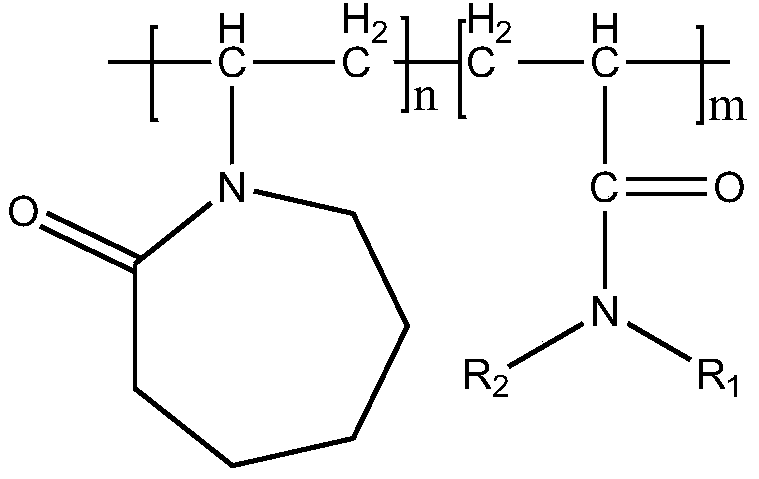

[0044] A kind of preparation method of natural gas hydrate inhibitor of the present invention specifically comprises the following steps,

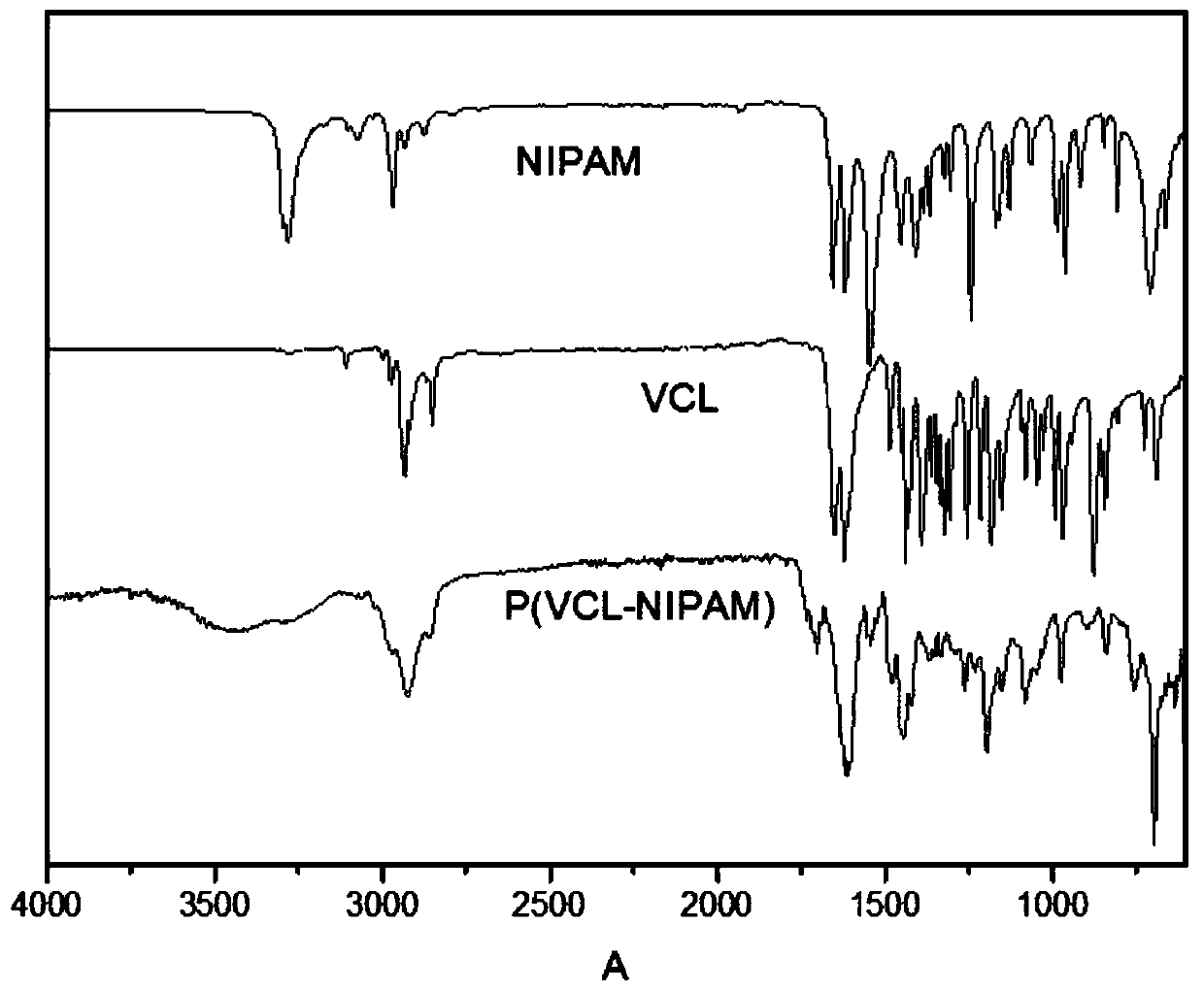

[0045] Step 1, add monomer N-vinylcaprolactam and N-isopropylacrylamide into deionized water, stir well and then add initiator azobisisobutyronitrile, these two monomers undergo free radical reaction in deionized water Polymerization;

[0046] Wherein, the mass ratio of the mass sum of two monomers to deionized water is 1:20, the mass ratio of monomer N-vinylcaprolactam and N-isopropylacrylamide is 3:1, and the mass ratio of initiator 1% of the sum of the mass of the two monomers, the reaction temperature of the radical polymerization reaction is 50°C, and the reaction time is 10h;

[0047] Step 2, after the reaction is completed, the reaction solution is filtered to obtain a solid product;

[0048] Step 3, put the obtained product into a beaker with a magnet, pour a certain amount of deionized water, wherein the mass ratio of deionized ...

Embodiment 2

[0055] A kind of preparation method of natural gas hydrate inhibitor of the present invention specifically comprises the following steps,

[0056] Step 1, add the monomers N-vinylcaprolactam and N-ethylacrylamide into deionized water, stir well and then add the initiator azobisisobutyronitrile, the two monomers undergo free radical polymerization in deionized water reaction;

[0057] Wherein, the mass ratio of the mass sum of the two monomers to deionized water is 1:22, the mass ratio of the monomer N-vinyl caprolactam and N-ethylacrylamide is 1:1, and the mass of the initiator is 3% of the mass sum of the two monomers, the reaction temperature of the radical polymerization reaction is 60°C, and the reaction time is 8h;

[0058] Step 2, after the reaction is completed, the reaction solution is filtered to obtain a solid product;

[0059] Step 3, put the obtained product into a beaker with a magnet, pour a certain amount of deionized water, wherein the mass ratio of deionized...

Embodiment 3

[0065] A kind of preparation method of natural gas hydrate inhibitor of the present invention specifically comprises the following steps,

[0066] Step 1, add monomer N-vinylcaprolactam and N,N dimethylacrylamide into deionized water, stir well and then add initiator azobisisobutyronitrile, these two monomers are free in deionized water radical polymerization;

[0067] Wherein, the mass ratio of the mass sum of the two monomers to deionized water is 1:25, the mass ratio of the monomer N-vinyl caprolactam and N,N dimethylacrylamide is 9:1, and the mass ratio of the initiator The mass is 4% of the sum of the masses of the two monomers, the reaction temperature of the radical polymerization reaction is 90°C, and the reaction time is 4h;

[0068] Step 2, after the reaction is completed, the reaction solution is filtered to obtain a solid product;

[0069] Step 3, put the obtained product into a beaker with a magnet, pour a certain amount of deionized water, wherein the mass rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com