Manual sample injector for sample pretreatment, manual sample injection method and application of manual sample injector

A sample pretreatment and manual sample injection technology, which is applied in the preparation of test samples, instruments, and analytical materials, etc., can solve the problems of complex and time-consuming pretreatment operations, reduce volume and complexity, expand application range, and reduce usage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] This example is used to illustrate a manual sampler for filtration pretreatment.

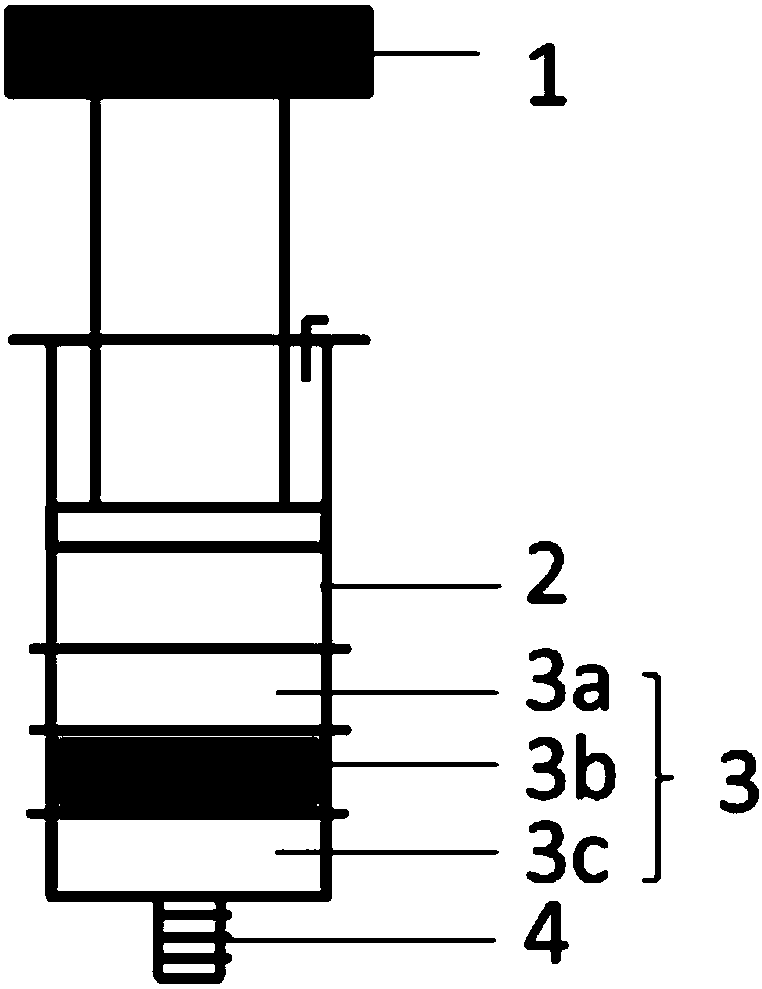

[0055] The manual sample injector used comprises a piston 1, a sample pool 2, a pretreatment part 3 and a sample outlet part 4, and the piston 1, the sample pool 2 and the pretreatment part 3 are all cylindrical and transparent glass materials.

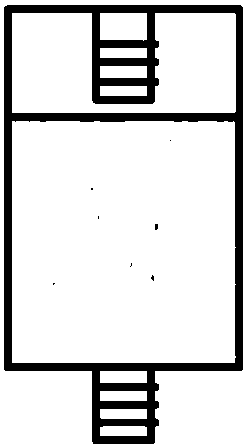

[0056] The preprocessing unit 3 is a filter module. The filter module is structured as figure 2 As shown, a polypropylene fiber filter disc is arranged inside; a sample inlet is arranged on the top, and an internal thread is arranged on the side wall of the sample inlet. A sample outlet is set at the bottom of the sample pool 2, an external thread is provided on the side wall of the sample outlet, the sample inlet of the pretreatment part 3 is screwed with the sample outlet of the sample pool 2, and the pretreatment part 3 and the sample pool 2 are screwed together. Removably sealed connection.

[0057] The sample outlet of the pretreatment p...

Embodiment 2

[0061] This example is used to illustrate the manual sampler for enrichment pretreatment.

[0062] The same manual injector as in Example 1 was used, except that the pretreatment part 3 was an enrichment module, and functional silica gel for enriching organic matter in the sample was provided inside.

[0063] Before starting the sample injection, open the piston 1, inject 1mL of turbid water sample into the sampler, close the piston 1, screw the sampler with the inlet of the micro-analysis chip, and then push the piston 1 to make the volume of the sample chamber Shrinking, the sample enters the micro total analysis chip for parameter analysis after being enriched with functional silica gel in the pretreatment part 3.

[0064] Remove the sampler from the micro-analysis chip and install it on another micro-analysis chip, open the piston 1, inject a certain amount of organic solvent such as methanol into the sample pool, cover the piston again and rotate it downwards. Pushing fo...

Embodiment 3

[0066] This example is used to illustrate a manual injector for pretreatment reactions.

[0067] The same manual injector as in Example 1 is used, the difference is that the pretreatment part 3 is a reaction reagent module, which is provided with mercury sulfate reagent for removing chloride in the water sample, and the reagent is sealed by a sieve plate.

[0068] Before starting the sample injection, open the piston 1 and inject 1mL of turbid water sample into the injector. The water sample contains the oxygen-consuming organic matter to be detected (the detection index is COD). The sample inlet of the chip is screwed, and then the piston 1 is pushed to reduce the volume of the sample chamber. The sample to be tested enters the pretreatment part under pressure, and the solid impurities in the water are removed through the filter module, and the chlorine in the water sample is removed through the reaction module. After compounding, enter the micro total analysis chip for analy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com