Flexible piezoelectric transducer and system

A flexible piezoelectric and transducer technology, applied in the field of acoustics, can solve the problems of poor energy superposition, limitations of miniaturization and integration, and short distance maintained in the propagation direction, achieve focused acoustic vortex stabilization, and improve equipment integration. The effect of superposition and enhancement of power and energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

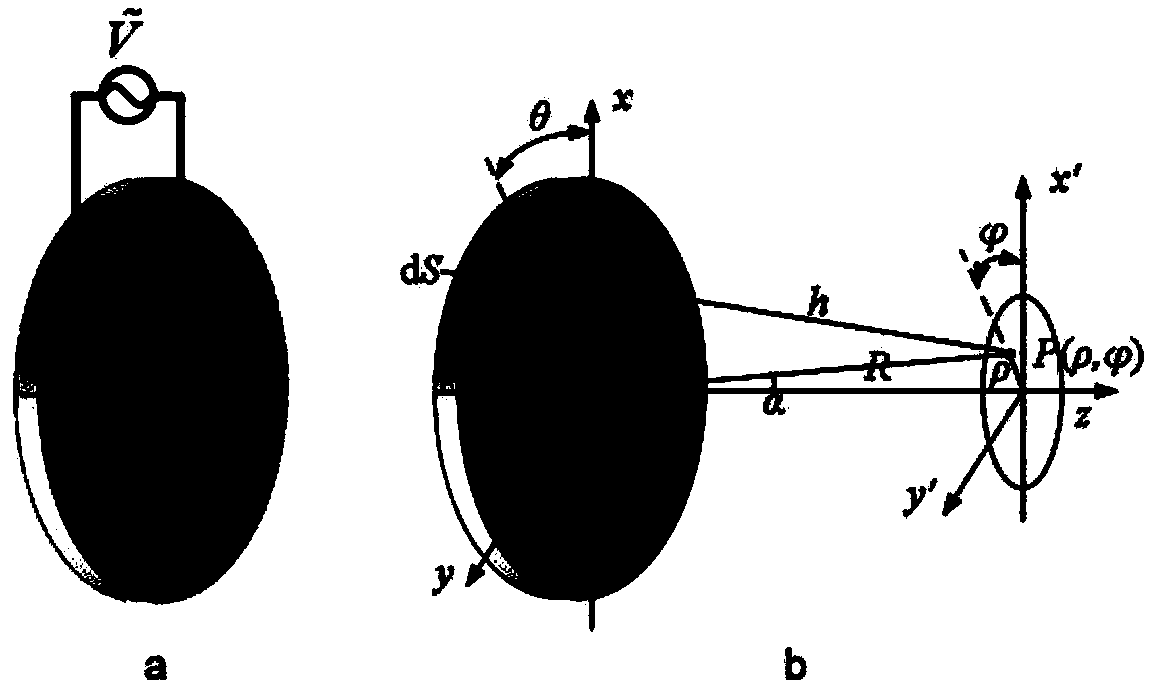

[0040] In order to break through the problem that the piezoelectric transducer array structure that generates the acoustic vortex wave velocity is complex and difficult to miniaturize, this embodiment abandons the array piezoelectric transducer structure, and creatively proposes a flexible piezoelectric transducer based on flexible substrates and flexible piezoelectric transducers. The thin-film non-array flexible piezoelectric transducer provides an effective way to solve the problem to be solved by the present invention.

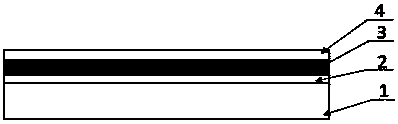

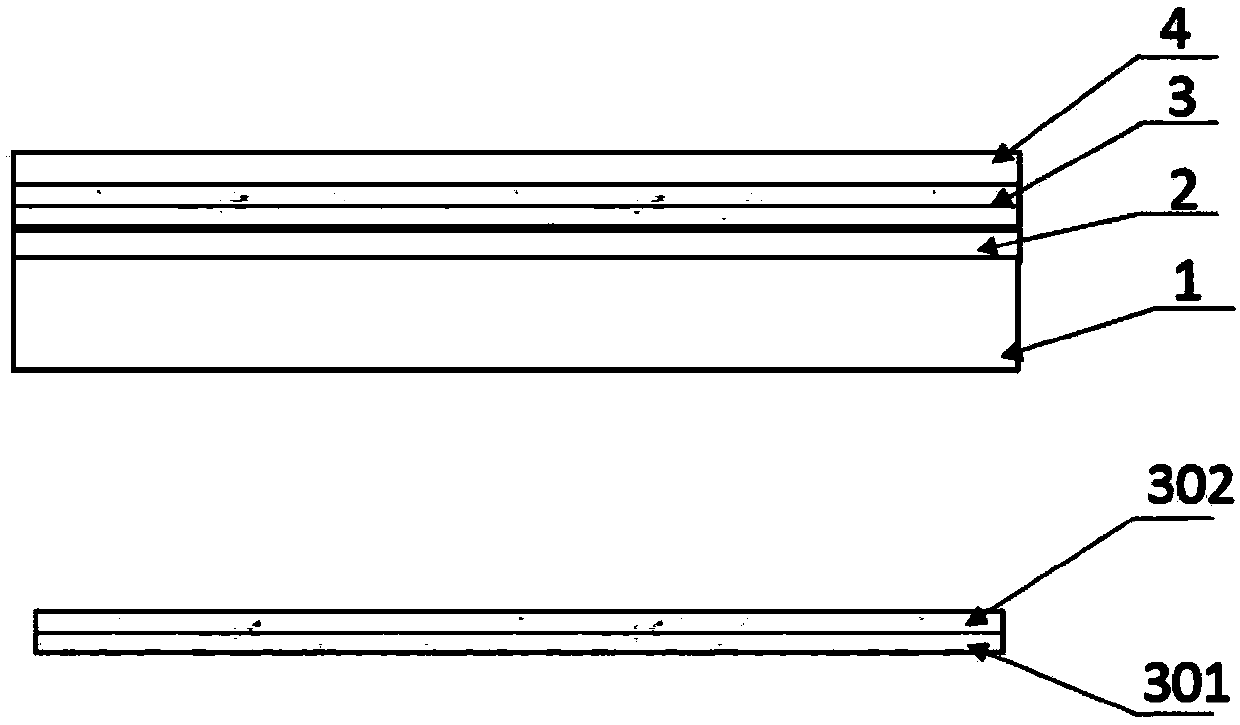

[0041] figure 2 is a schematic structural diagram of the flexible piezoelectric transducer provided in this embodiment. like figure 2 As shown, in this embodiment, the flexible PVDF piezoelectric film is covered on the flexible substrate, and the material of the flexible substrate is a material with strong deformation capacity and ductility, preferably: ethylene phthalate (PET) , polycarbonate (PC) or polyimide (PI). Specifically, the flexible piezoel...

example 1

[0057] When there are multiple equiangular spiral electrode strips, taking 4 spiral arms as an example, the initial inner diameter a 1 =13.8mm, initial outer diameter a 2 =14.85mm, the azimuth coefficients of the spiral electrodes corresponding to the topological charges l being 1, 2, 3 and 4 are respectively b 1 =0.0225,b 2 =0.0451,b 3 =0.0676,b 4 =0.0902, the end angles of the azimuth angles are θ 1 =12π, θ 2 =6π, θ 3 = 4π, θ 4 = 3π. At this time, the minimum width of the equiangular spiral electrode strip is d min = 1mm, the maximum width of the equiangular spiral electrode strip is d max =2.47mm, after applying the sinusoidal excitation signal of the same frequency and phase, it can generate 305kHz~750kHz vortex sound wave.

example 2

[0059] When the equiangular spiral electrode strip is a single strip, the initial inner diameter is 13.8mm, the initial outer diameter is 14.85mm, the azimuth angle coefficient b=0.0225, the azimuth angle θ rotates from 0 to 12π, and 425kHz can be generated after applying a sinusoidal excitation signal Vortex sound waves.

[0060] Both the flexible substrate and the PVDF piezoelectric film can be bent under different conditions. see Figure 4 , which shows a schematic diagram of the deformation of the flexible piezoelectric transducer under different force conditions. Figure 5 Shows the zoom spot depth of the flexible substrate and the PVDF piezoelectric film in the change of force bending and extension. The flexible substrate provided with the PVDF piezoelectric film is concave spherical in use. Change, the flexible substrate changes the radius of curvature through bending deformation, and then realizes the variable focal spot depth. Figure 5 R in SR is the curvature of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com