Six-freedom-degree welding robot line laser real-time seam tracking method

A robot line and degree of freedom technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of difficult visual image processing, excessive distance between laser stripes and welding pool, etc., and achieve simple system structure and enhanced real-time permanent, easy-to-maintain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

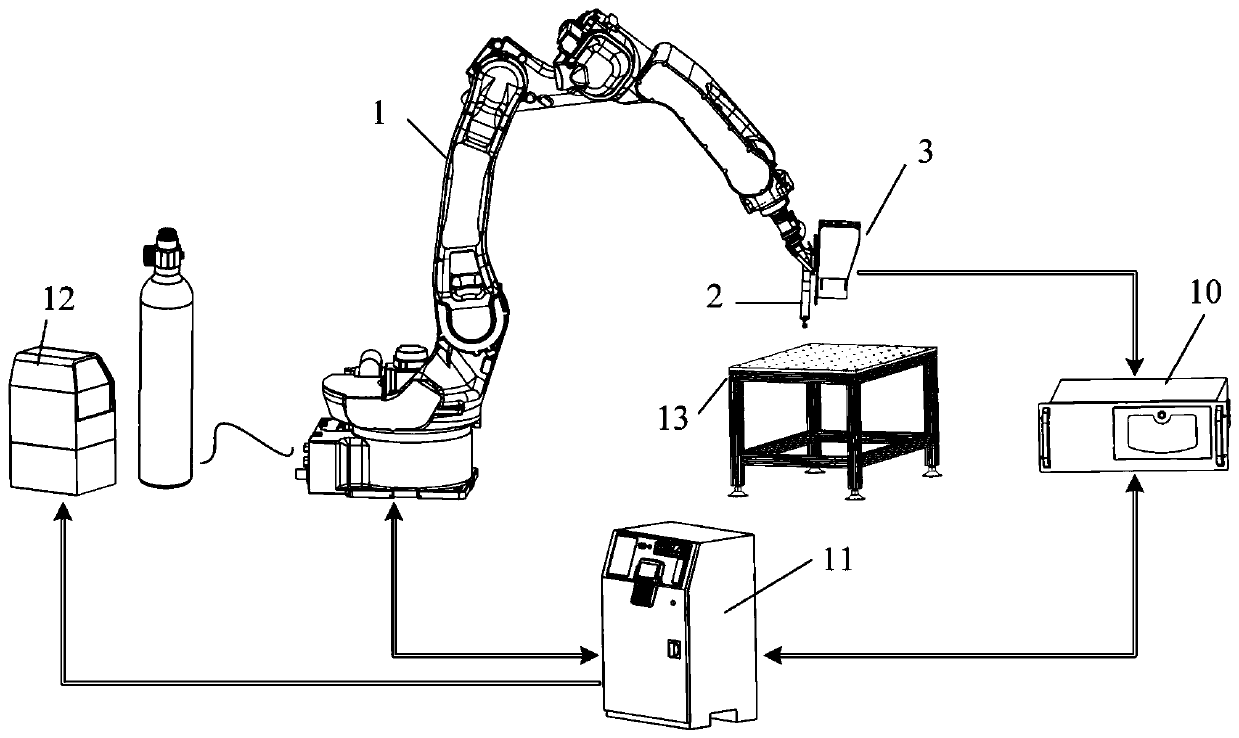

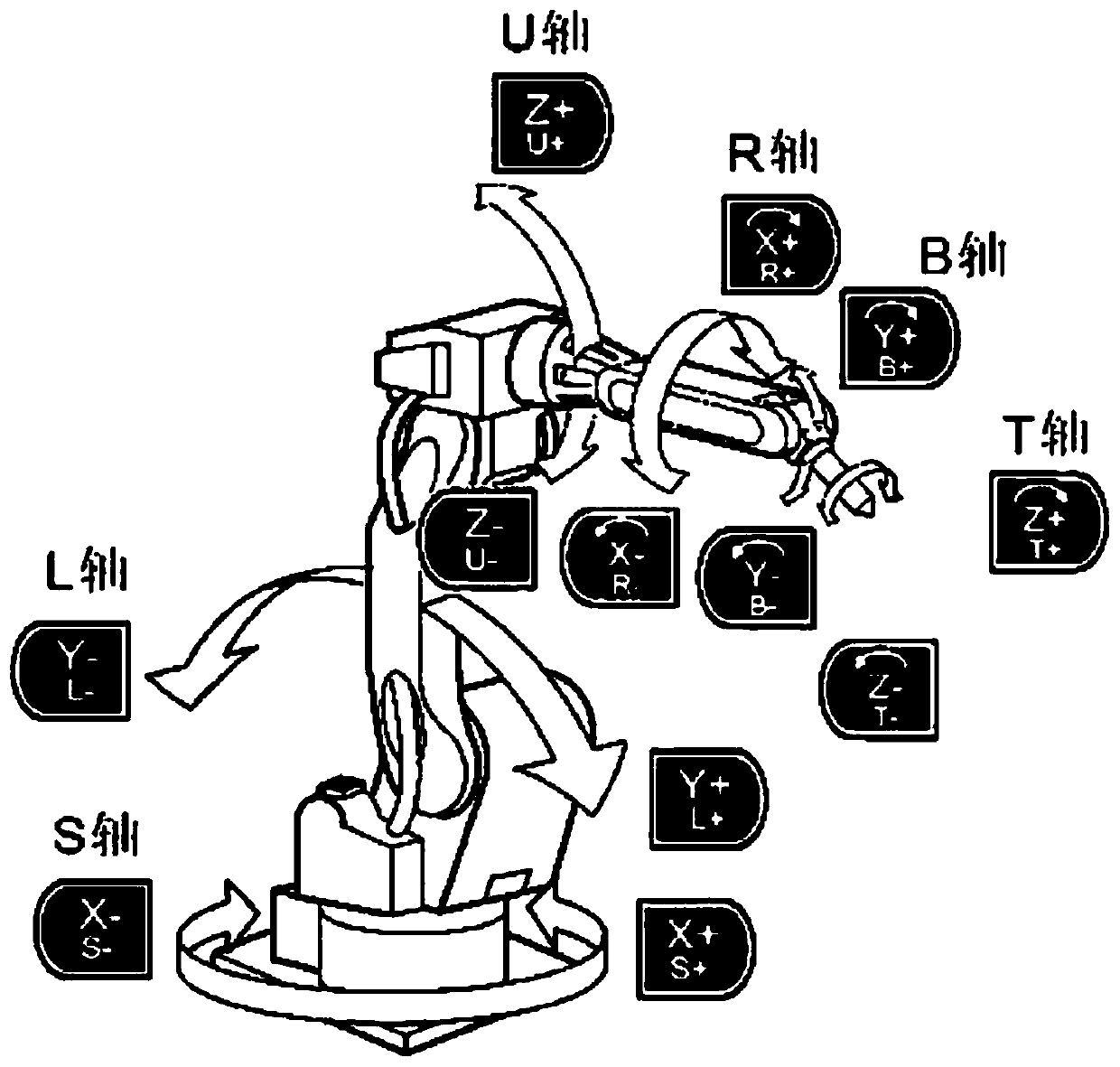

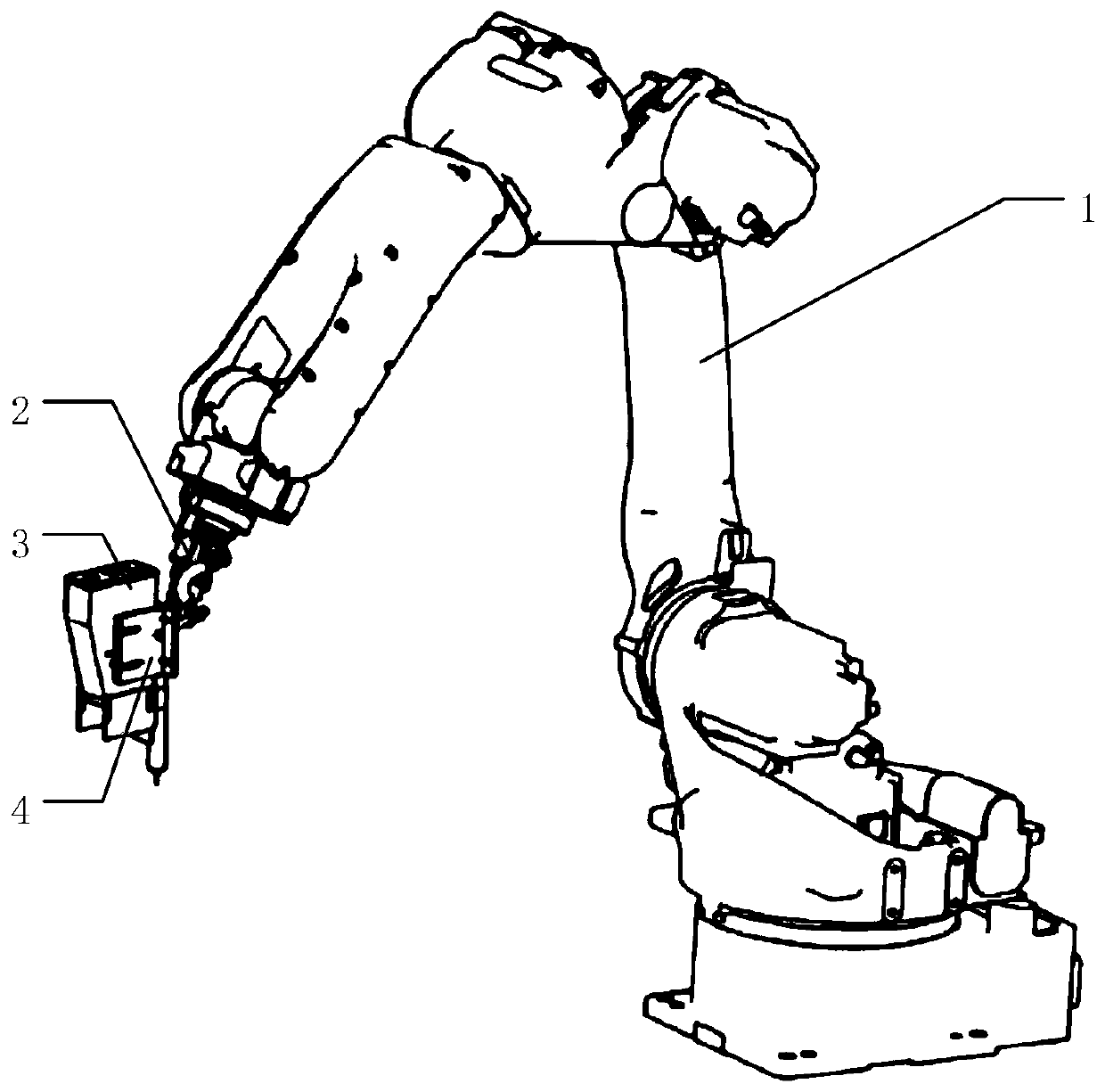

[0060] Such as figure 1 As shown, a six-degree-of-freedom welding robot line laser real-time seam tracking method, the tracking system based on the method includes a six-degree-of-freedom mechanical arm 1, a welding torch 2, a line laser vision sensor 3, a workbench 13, an automatic welding machine 12, The wire feeding mechanism, the embedded industrial controller 10, the control cabinet 11, the workpiece 9 is placed on the workbench 13, the line laser vision sensor 3 is installed on the welding torch 2 through the installation base 4, and the welding torch 2 is placed on the six-degree-of-freedom mechanical arm 1 At the end, the line laser vision sensor and the welding gun change their positions in space through the movement of the six-degree-of-freedom mechanical arm. The welding wire is stored in the container and sent to the welding torch through the conduit and the wire feeding device. The wire feeding device is fixed on the U-axis of the six-degree-of-freedom mechanical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com