Copper-based material surface icing-delaying structure and preparation method thereof

A copper-based, copper-based technology, applied in the field of copper-based material surface delayed icing structure and its preparation, can solve the problems of work efficiency impact, reduced practical rate, copper-based material surface performance can not meet the requirements of specific working conditions, etc., to achieve Effect of increased roughness, increased contact area, and good icing delay performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Step 1: Prepare the copper-based material into a size of 20mm×10mm×2mm by wire cutting; then polish the cut copper substrate on 600-mesh, 1000-mesh, 1500-mesh, and 2000-mesh sandpaper to make the surface smooth;

[0019] Step 2: Polish the copper substrate on a polishing machine to make the surface of the substrate smooth; then place the copper substrate in alcohol for ultrasonic cleaning for 5 minutes; dry the cleaned copper substrate briefly, and observe the surface whether it is cleaned;

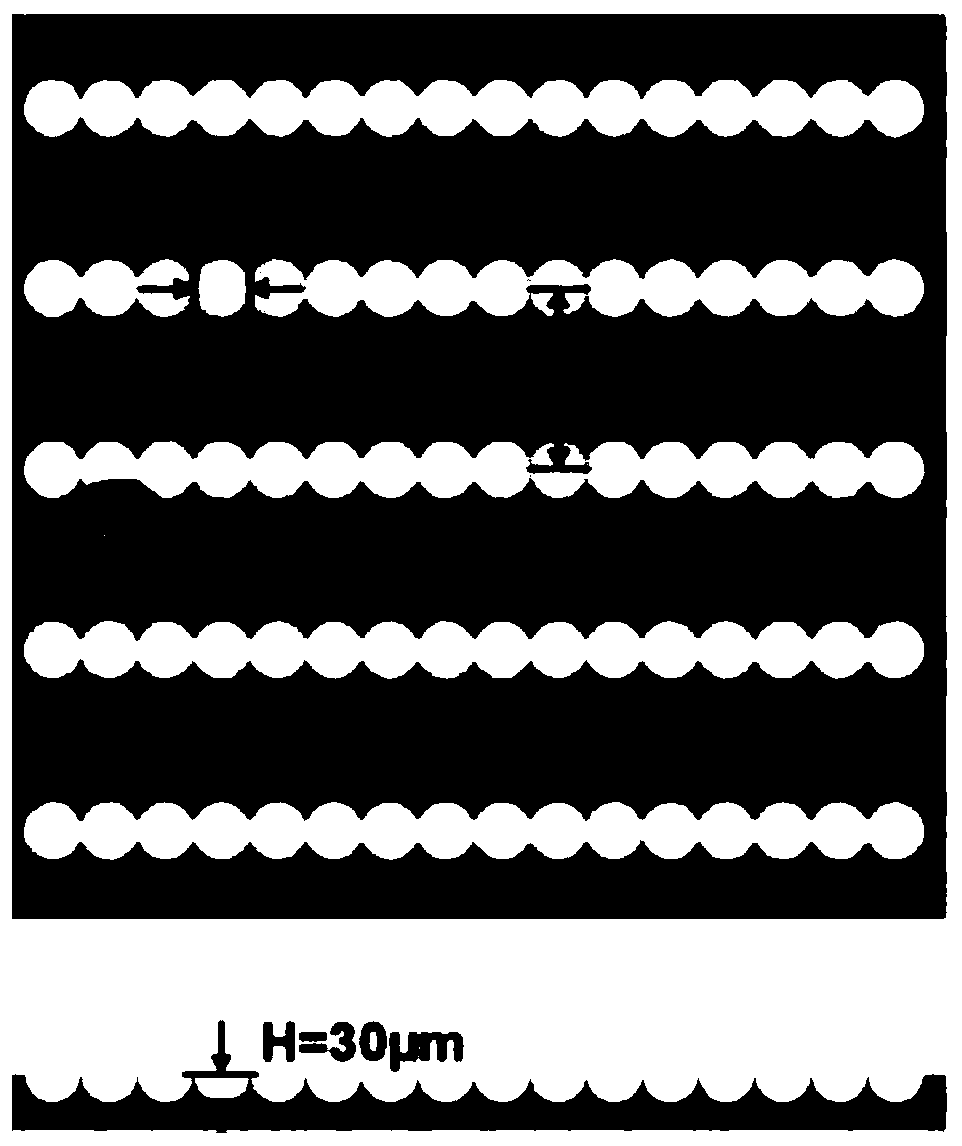

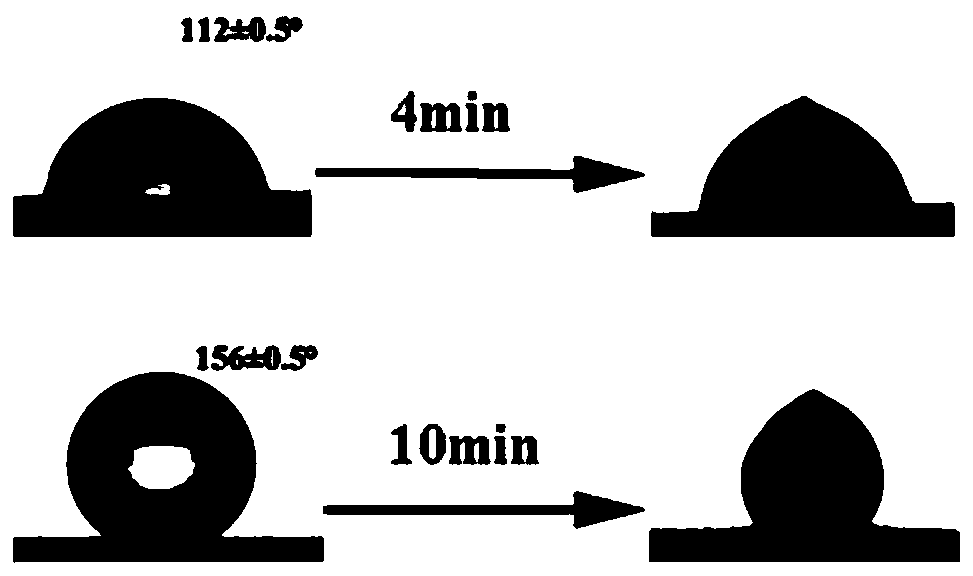

[0020] Step 3: Prepare a concave matrix structure on the surface of the dried copper substrate by laser, such as figure 1 shown, where the diameter of each concave structure Depth (H) 30μm, row spacing (L) 50μm, column spacing 100μm, laser processing parameters: frequency 20HKz, power 16w, scanning speed 1800mm / s, processing times 2 times;

[0021] Step 4: Place the laser-processed copper substrate in ionized water, acetone, and deionized water for ultrasonic cleaning for 5 minu...

Embodiment 2

[0024] Step 1: Prepare the copper-based material into a size of 20mm×10mm×2mm by wire cutting; then polish the cut copper substrate on 600-mesh, 1000-mesh, 1500-mesh, and 2000-mesh sandpaper to make the surface smooth;

[0025] Step 2: Polish the copper substrate on a polishing machine to make the surface of the substrate smooth; then place the copper substrate in alcohol for ultrasonic cleaning for 5 minutes; dry the cleaned copper substrate briefly, and observe the surface whether it is cleaned;

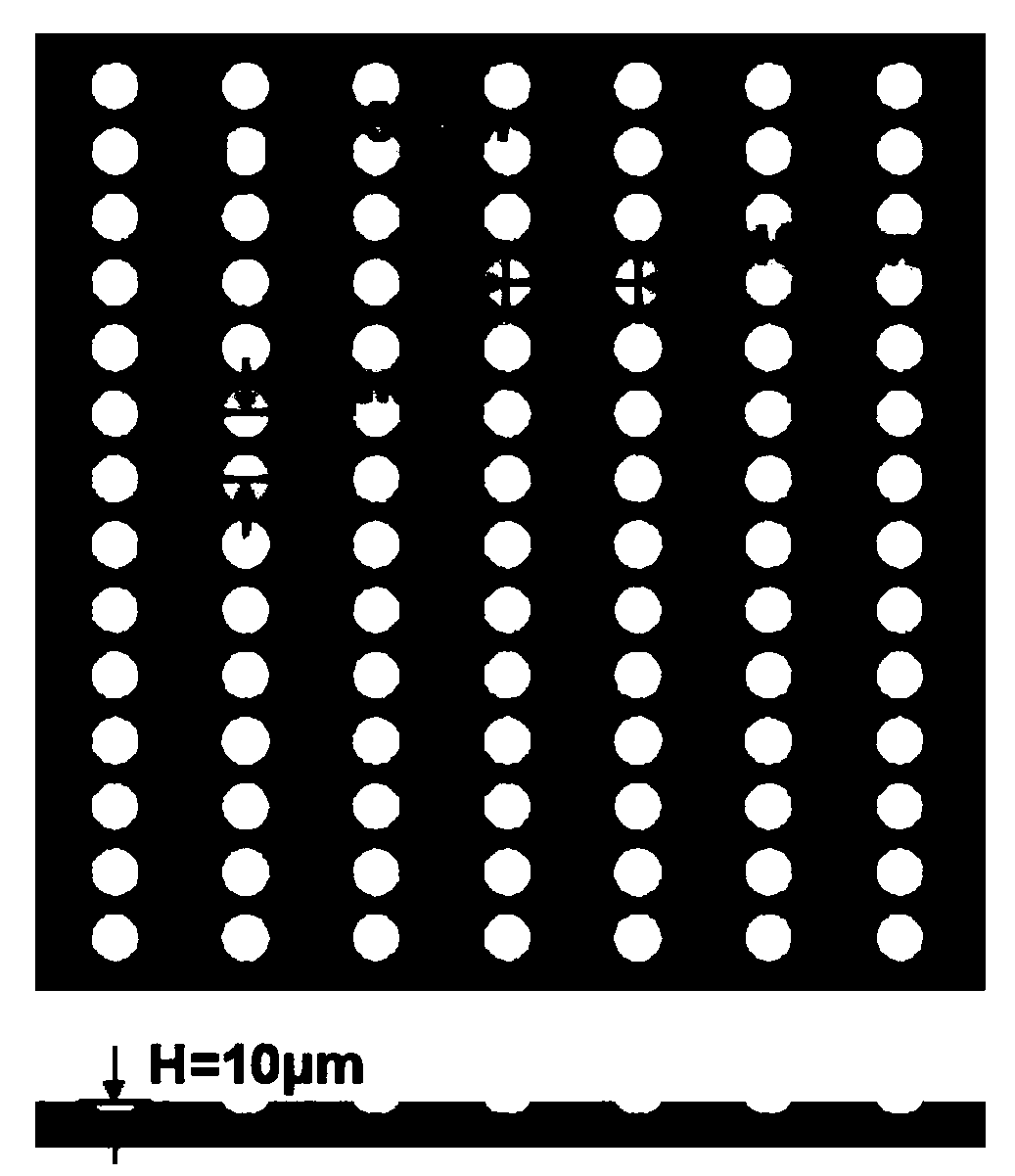

[0026] Step 3: Using a laser to prepare a concave matrix structure on the surface of the dried copper substrate, wherein the diameter of each concave structure is Depth (H) 10μm, row spacing (L) 100μm, column spacing 50μm, laser processing parameters: frequency 20HKz, power 16w, scanning speed 1800mm / s, processing times 2 times;

[0027] Step 4: Place the laser-processed copper substrate in ionized water, acetone, and deionized water for ultrasonic cleaning for 5 minutes; then dr...

Embodiment 3

[0030] Step 1: Prepare the copper-based material into a size of 20mm×10mm×2mm by wire cutting; then polish the cut copper substrate on 600-mesh, 1000-mesh, 1500-mesh, and 2000-mesh sandpaper to make the surface smooth;

[0031] Step 2: Polish the copper substrate on a polishing machine to make the surface of the substrate smooth; then place the copper substrate in alcohol for ultrasonic cleaning for 5 minutes; dry the cleaned copper substrate briefly, and observe the surface whether it is cleaned;

[0032] Step 3: Using a laser to prepare a concave matrix structure on the surface of the dried copper substrate, wherein the diameter of each concave structure is Depth (H) 30μm, row spacing (L) 50μm, column spacing 50μm, laser processing parameters: frequency 20HKz, power 16w, scanning speed 1800mm / s, processing times 2 times;

[0033] Step 4: Place the laser-processed copper substrate in ionized water, acetone, and deionized water for ultrasonic cleaning for 5 minutes; then dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com