Injection molding process for ultrahigh-flatness liquid crystal screen supporting panel

An injection molding process and a technology for supporting panels, which are applied to flat products, household appliances, and other household appliances, can solve problems that cannot be completely eliminated, and achieve high pass rate, guaranteed sealing, and low cost and energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

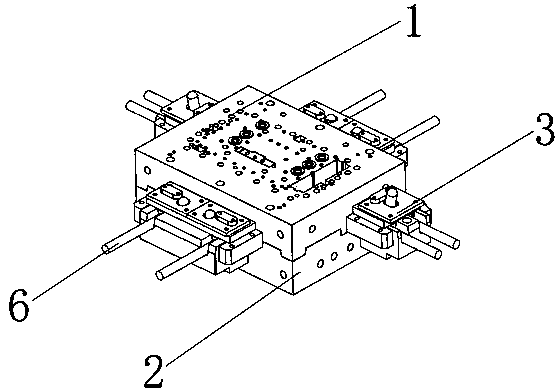

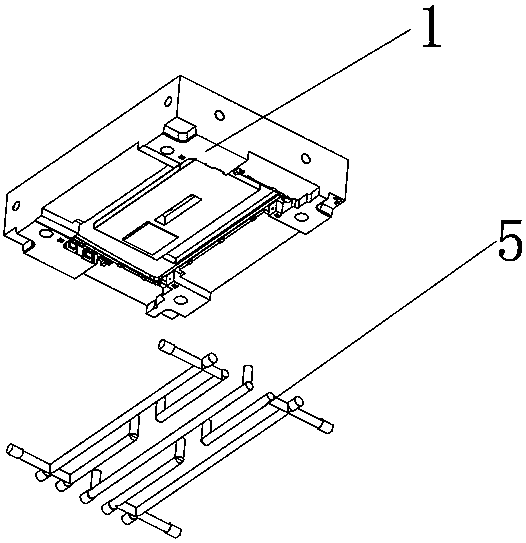

[0037] see Figure 1-12 , the present invention provides a technical solution: an ultra-high flatness liquid crystal screen support panel injection molding process, including an ultra-high flatness liquid crystal screen support panel injection molding process, the process includes the following steps:

[0038] The first step: in the composite material drying stage, the PC and ABS composite materials are dried;

[0039] The second step: in the melting stage, the dried composite material is fed into the injection molding machine;

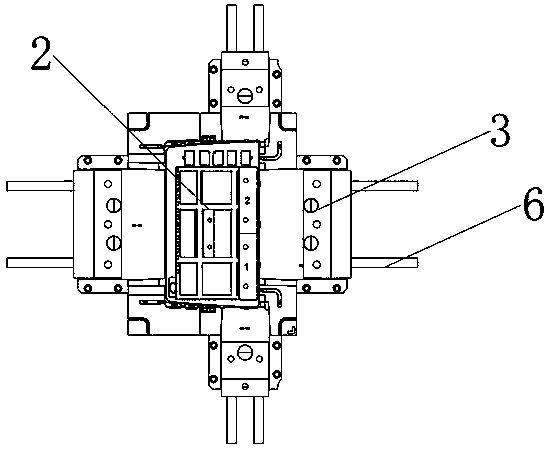

[0040] Step 3: In the temperature control stage of mold processing, the fixed mold 1 of the mold is connected to the refrigerator 2, the movable mold 2 of the mold is connected to the oil temperature controller, and the sliders 3 on both sides of the fixed mold 1 and the movable mold 2 are connected to the water temperature controller;

[0041] Step 4: In the injection molding stage, inject the molten liquid flow from the barrel nozzle of the injecti...

Embodiment 2

[0050] The pipeline connection assembly 7 includes a first connecting pipe 8, a second connecting pipe 9 and a shrinking mechanism 10, and the first connecting pipe 8 and the second connecting pipe 9 are fixedly connected by the shrinking mechanism 10, so The ends of the first connecting pipe 8 and the second connecting pipe 9 far away from the contracting mechanism 10 are provided with a clamping mechanism 11, the first connecting pipe 8 is clamped with the water temperature pipe 6 through the clamping mechanism 11, The end of the second connecting pipe 9 away from the retracting mechanism 10 is engaged with the output end of the water cooler through the engaging mechanism 11 .

[0051] The retraction mechanism 10 includes a retraction rod 12 and a ring spring 13, the ring spring 13 is sleeved on the retraction rod 12, and the two ends of the retraction rod 12 and the ring spring 13 are respectively connected with the first connecting pipe 8 and the One end of the second conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com