Sewage treatment method

A sewage treatment method, plasma technology, applied in the sewage treatment field of plasma technology, can solve the problems of slow purification rate, electrode corrosion, unbalanced plasma discharge failure, etc., to improve the purification flow, increase the liquid flow, and improve the purification efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

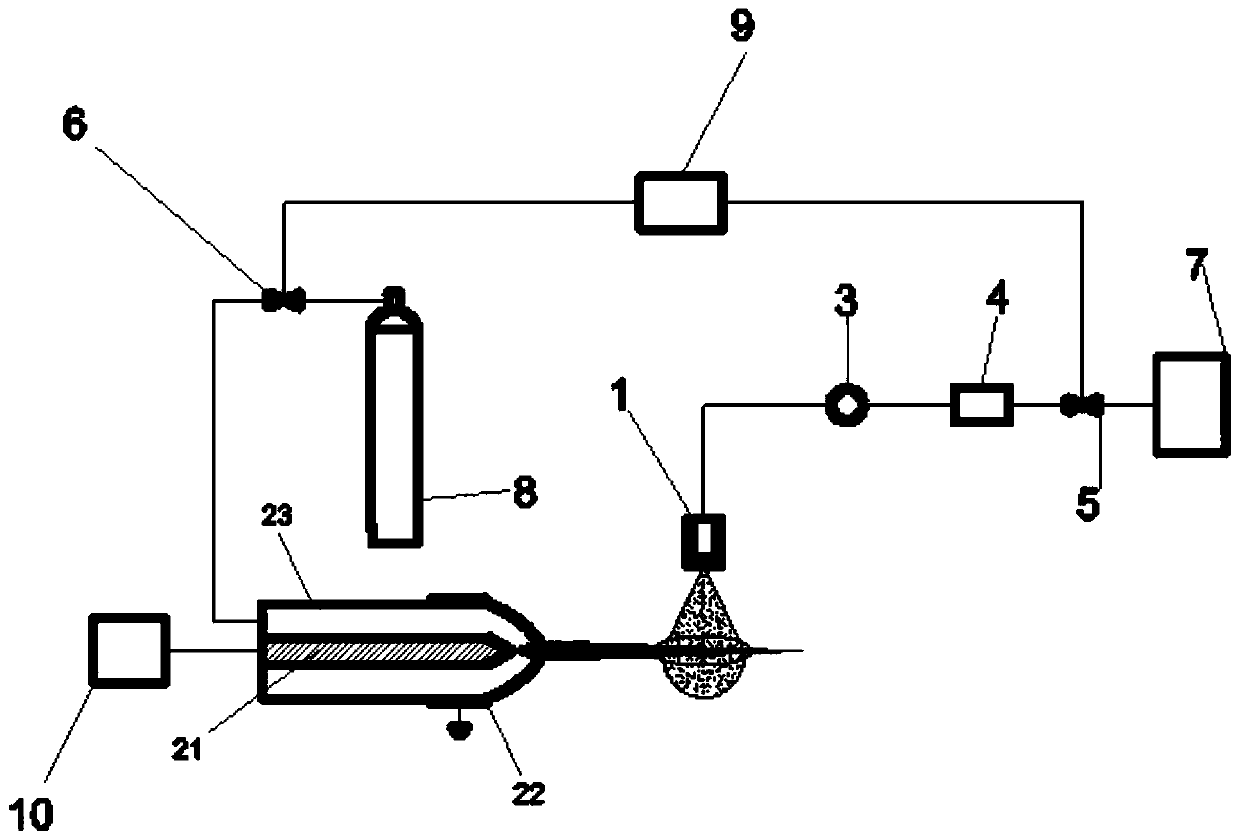

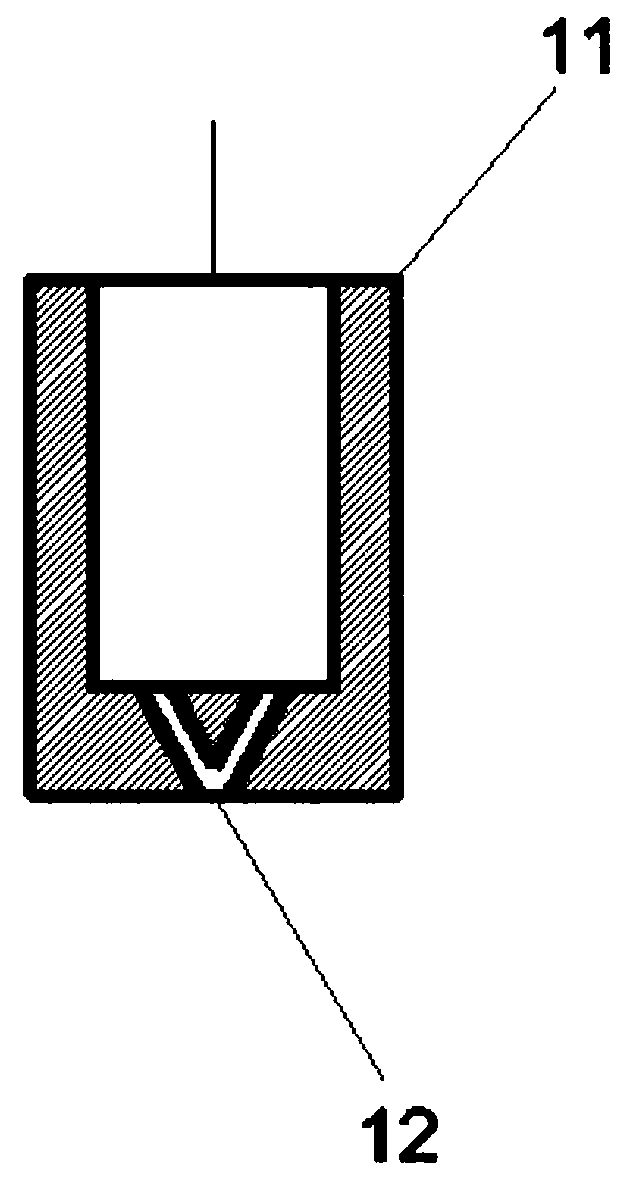

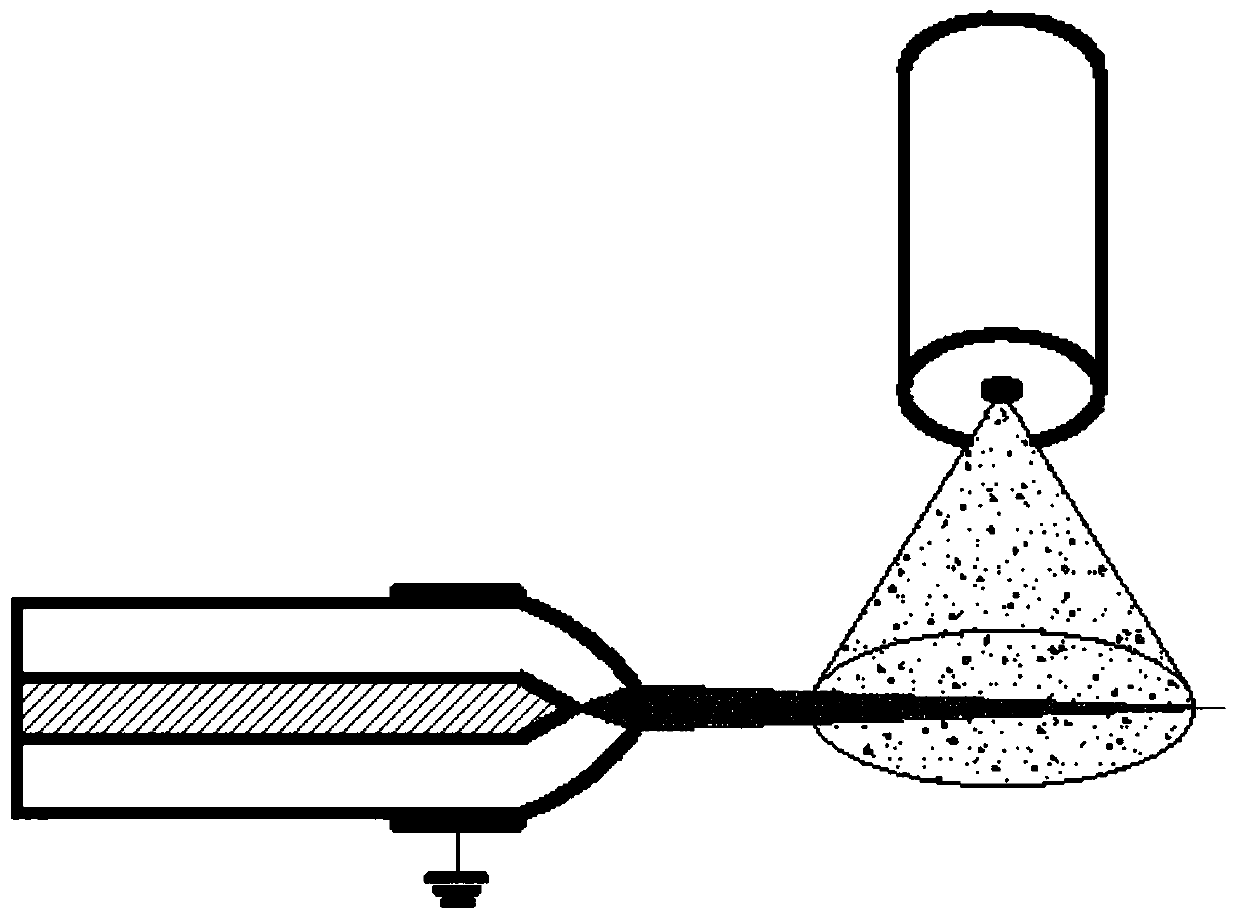

[0028] This embodiment provides a sewage treatment device, including: a liquid atomizer, an unbalanced plasma jet actuator, a flow meter, a filter, a liquid flow control valve, a gas flow control valve, a liquid storage tank, a high-pressure gas cylinder, and a valve Opening electronic controller, plasma power supply; the liquid atomizer is connected to the liquid storage tank through a flow meter, a filter, and a liquid flow control valve in sequence, and the liquid flow control valve is also connected to the valve opening electronic controller One end, the other end of the valve opening electronic controller is connected to the gas flow control valve, the gas flow control valve is located on the pipeline between the high-pressure gas cylinder and the unbalanced plasma jet actuator, the unbalanced plasma The jet exciter is connected with the plasma power supply, and the injection area at the bottom of the liquid atomizer overlaps with the jet area at one side of the unbalanced...

Embodiment 2

[0036] The present embodiment provides a sewage treatment method, comprising the steps of:

[0037] S1: The plasma power supply supplies power to the high-voltage electrode or the ground electrode with a certain voltage, and forms an electric field in the space between the high-voltage electrode and the ground electrode;

[0038] S2: The valve opening electronic controller controls the opening of the gas flow control valve, and the high-pressure gas in the high-pressure gas cylinder enters the electric field space through the gas flow control valve to form a plasma jet and eject it;

[0039] S3: The valve opening electronic controller controls the opening of the liquid flow control valve, and the liquid to be treated in the liquid reservoir passes through the liquid flow control valve, filter, and flow meter and is sprayed out in the form of a spray under the action of the liquid atomizer. And all spray fields pass through the non-equilibrium plasma jet region;

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap