Preparation methods of mixture, powder nano synergist, and nitro-compounded fertilizer

A nitro compound fertilizer and nano synergistic technology, which is applied in the direction of fertilizer mixture, ammonium nitrate fertilizer, nitrogen fertilizer, etc., can solve the problems of single function and single structure of nano synergist, and achieve the effect of simple preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A kind of preparation method of the mixture of modified calcium chloride and attapulgite powder provided by the embodiment of the present invention comprises the following steps:

[0032] S1, you can take 15-23 parts of calcium chloride powder (by mass, the same below), 70-90 parts of attapulgite powder, 0.2-0.7 parts of octadecylamine and 0.2-0.7 parts of ammonium dodecylsulfonate are mixed and added Pour into a container to form a powdery mixture. When preparing in small quantities, the container can be a beaker; when producing in large quantities, the container can be a large stainless steel reaction vessel.

[0033] S2. The powdery mixture can be acid-treated, and then the powdery mixture can be neutralized.

[0034] S3. The powdery mixture can be dried to obtain a modified calcium chloride and attapulgite powder mixture with a nanoporous (microporous) structure. The prepared mixture can be sealed for future use.

[0035] Understandably, calcium chloride can be u...

Embodiment 1

[0060] Experimental parameters:

[0061] Case 1:

[0062] ①Choose 65 parts of modified calcium chloride and attapulgite powder, 15 parts of calcium propionate, 15 parts of chitosan, and 5 parts of dimethylpyrazole phosphate to prepare powdery nano synergist; Add 0.2 parts of the prepared powdery nano synergist (N, P and K content ratio is 18:8:18, the following cases are the same) to the fertilizer to make a new nitro compound fertilizer finished product.

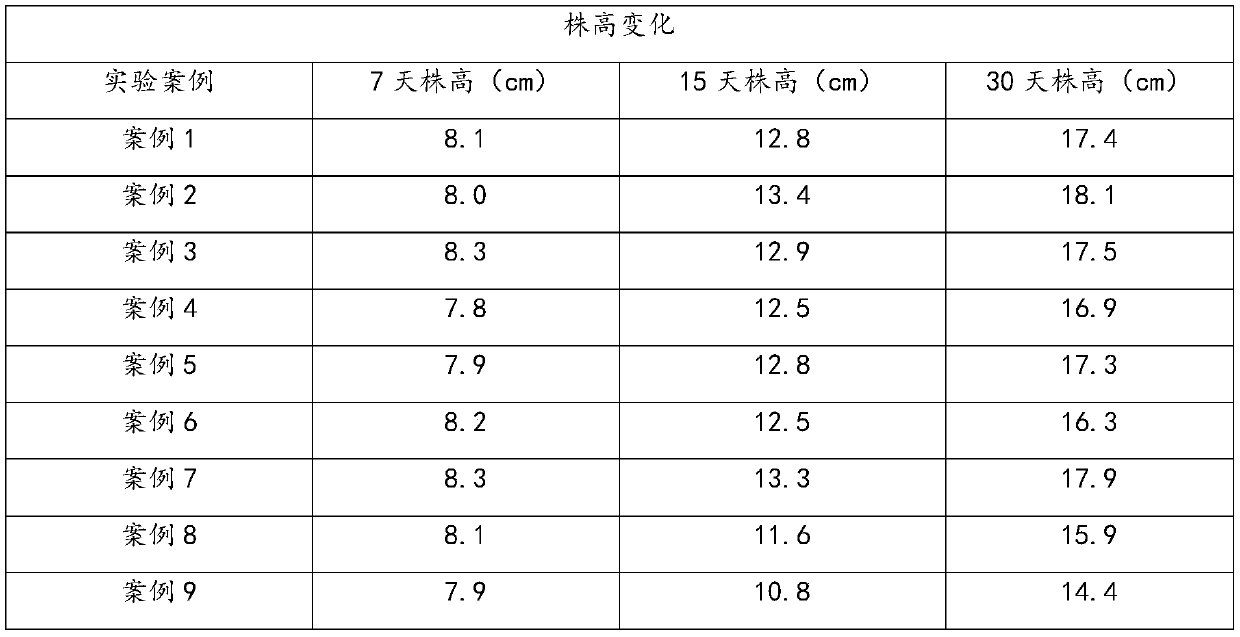

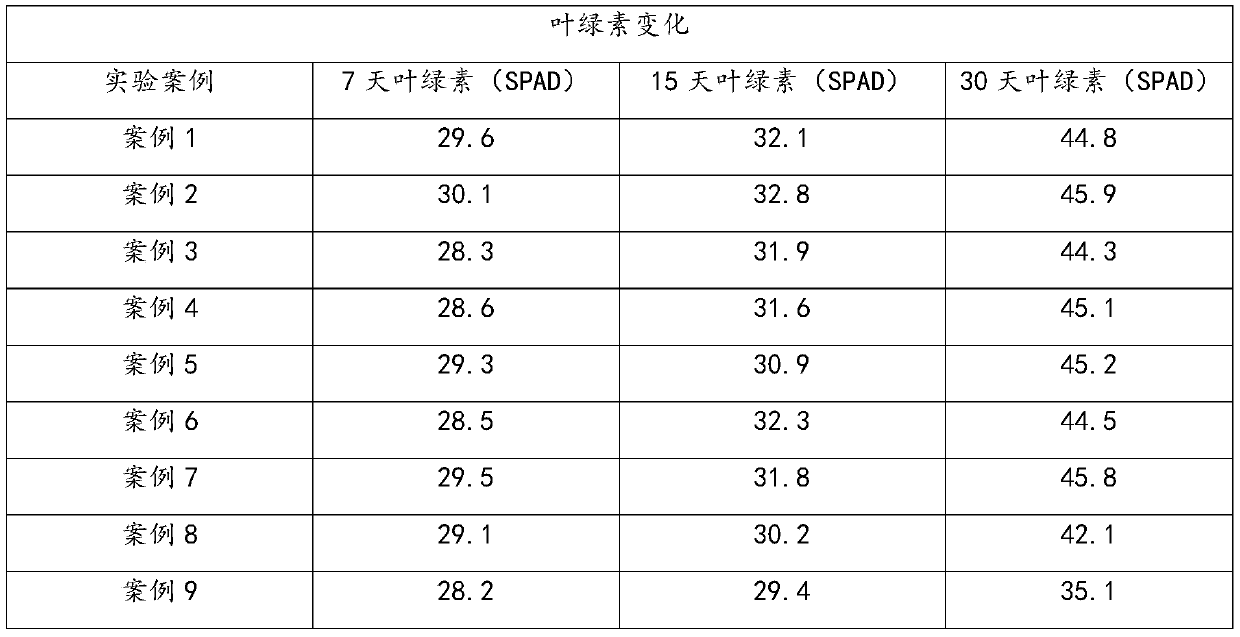

[0063] ②Apply the finished product to the land at one time with 80kg / mu as the base fertilizer, plant Shanghai Qingming, measure the plant height and chlorophyll content of Shanghai Qingming at 7, 15, and 30 days respectively, and measure the leaf width and vitamin C content of Shanghai Qingming on the 30th day.

[0064] Case 2:

[0065] ①Choose 70 parts of modified calcium chloride and attapulgite powder, 15 parts of calcium propionate, 10 parts of chitosan, and 5 parts of dimethylpyrazole phosphate to prepare powdery na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com