Preparation method of novel dextrin and application of the novel dextrin in dialysate

A technology of peritoneal dialysis fluid and dextrin, applied in the field of peritoneal dialysis, can solve the problems of large osmotic pressure range, large dextrin molecular number range, etc., and achieve the effects of narrow osmotic pressure range, concentrated range and broad market application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

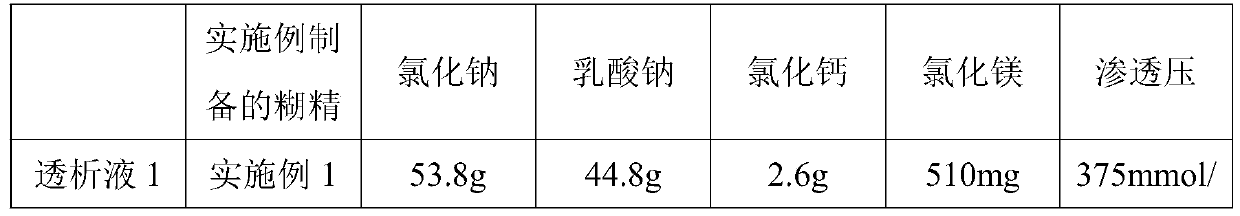

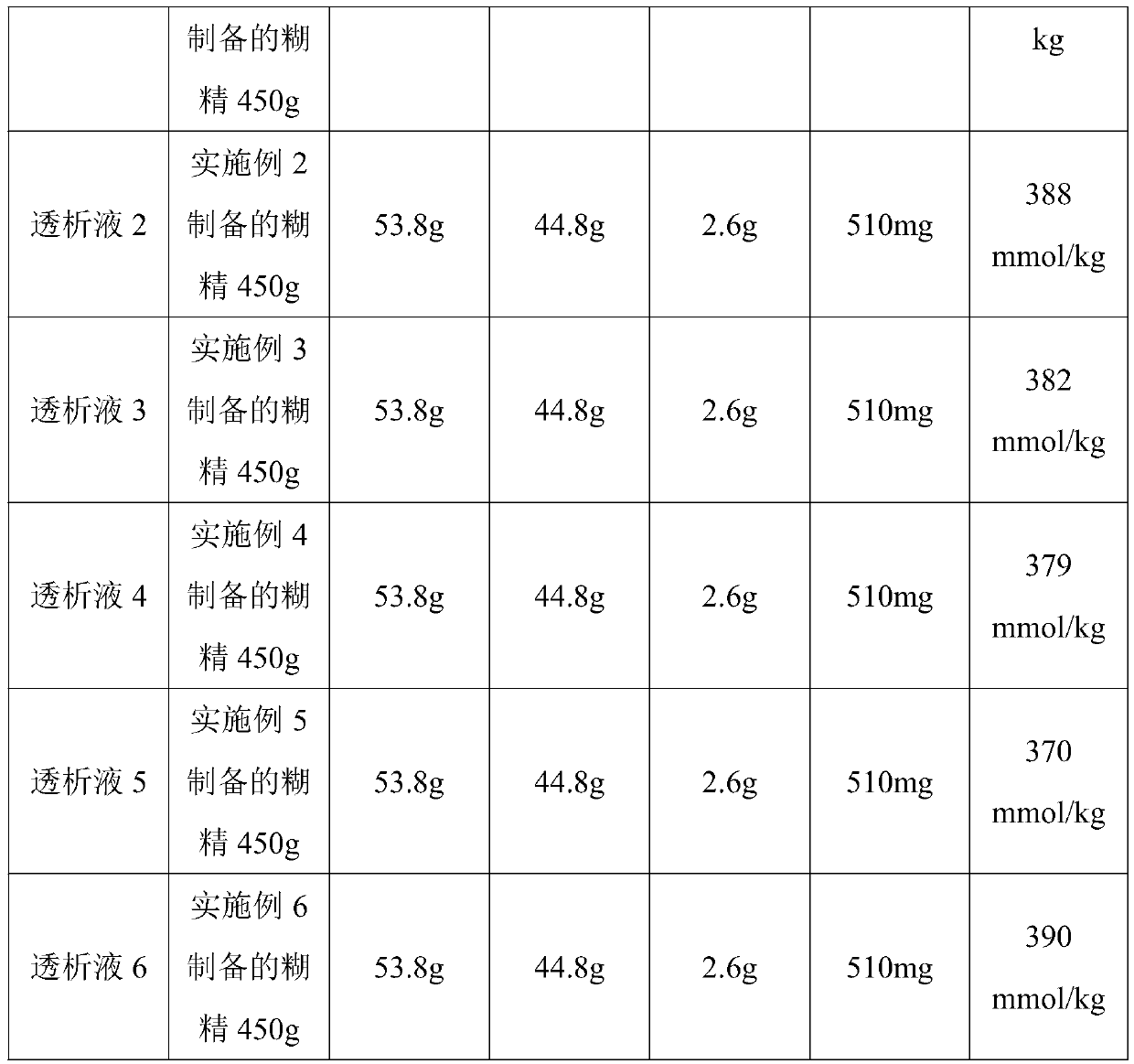

[0027] In order to solve the problem of large osmotic pressure range caused by the large range of existing dextrin molecules, the present invention provides a preparation method of novel dextrin and its application in dialysate, specifically the dextrin prepared by the method of the present invention is used as Application of osmotic agents in dialysate. The acid described in the method of the present invention is hydrochloric acid, glacial acetic acid or sulfuric acid, wherein said hydrochloric acid can be concentrated hydrochloric acid, also can be the dilute hydrochloric acid of mass percent concentration ≥ 10%, and described sulfuric acid can be concentrated sulfuric acid, also can be mass percent Dilute sulfuric acid with a percentage concentration ≥ 10%. The membrane bag used in the present invention is GK1812 model and PT1812 model of SUEZ company, also can be replaced by other products with the same effect. The model of the spray dryer used is Yacheng YC-019, and it c...

Embodiment 1

[0031] Add 10,000ml of water to the reaction kettle, start stirring, then add 10,000g of cornstarch, and after stirring evenly, make a starch slurry with a mass percentage concentration of 50%, add 10% dilute hydrochloric acid to make the mass percentage concentration of the acid in the entire system 3%, keep it warm at 65°C, carry out the hydrolysis reaction for 6 hours, add 5 times the amount of cooling water to cool the reaction solution to room temperature, first filter it with a Suez GK1812 3000 membrane, remove the substances with a molecular weight less than 3000, and retain the large molecular weight Parts, and then filter with PT1812 5000 membrane to remove substances with molecular weight greater than 5000, retain the part with molecular weight less than 5000, collect the molecular weight of substances in the liquid with a molecular weight of 3000-5000, and then use Yacheng YC-019 spray dryer to spray Drying at a drying temperature of 150° C., a drying time of 8 hours...

Embodiment 2

[0033] Add 10,000ml of water to the reaction kettle, start stirring, then add 6666.7g of potato starch, and after stirring evenly, make a starch slurry with a mass percentage concentration of 40%, add 37% concentrated hydrochloric acid to make the mass percentage of the acid in the whole system The concentration is 5%, the temperature is kept at 70°C, the hydrolysis reaction is carried out for 5 hours, 8 times the amount of cooling water is added to cool the reaction solution to room temperature, and the membrane filter with Suez GK1812 3000 is used to remove the substances with a molecular weight less than 3000, and the molecular weight The larger part is then filtered with a PT1812 5000 membrane to remove substances with a molecular weight greater than 5000, and retain the part with a molecular weight less than 5000. The molecular weight of the substances in the collected liquid is 3000-5000, and then use Yacheng YC-019 spray dryer for Spray drying, drying temperature 120 ° C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com