Water-dispersible polymer crude oil viscosity reducer as well as preparation method and application thereof

A crude oil viscosity reducer and polymer technology, applied in the field of materials, can solve the problems of large application limitations, poor high temperature resistance, etc., and achieve good viscosity reduction effect, good emulsification and solubilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: the preparation of polymer viscosity reducer P1

[0029] In a beaker, weigh 12g acrylic acid, 1.8g styrene, 1.8g vinyl silicone oil (both ends are terminated with vinyl, 5wt% vinyl, viscosity is 1000cP, purchased from Jinan Xingfeilong Chemical Co., Ltd.), 14.4g Octadecyl methacrylate, 0.27g of 2,2'-azobisisobutyronitrile, and 15g of n-butanol as a solvent were stirred until completely dissolved and then transferred to the dropping funnel. Add 15g of n-butanol and 0.03g of 2,2'-azobisisobutyronitrile into the three-necked flask. At 90°C, add the mixed liquid dropwise into the flask, and control the dropwise addition of the liquid in the funnel within 1 hour. After the dropwise addition is completed, continue the constant temperature reaction for 2 hours. Raise the temperature to 100°C, add 0.15 g of initiator 2,2'-azobisisobutyronitrile, and continue the reaction at constant temperature for 1 h. Cool down to 60°C, add 14.83g of N,N-dimethylethanolamine, ...

Embodiment 2

[0030] Embodiment 2: the preparation of polymer viscosity reducer P2

[0031] In a beaker, weigh 12g acrylic acid, 1.8g styrene, 1.8g vinyl silicone oil (5% vinyl, viscosity is 1000cP, purchased from Jinan Xingfeilong Chemical Co., Ltd.), 28.8g octadecyl methacrylate, 0.27g 2,2'-azobisisobutyronitrile, 15g solvent n-butanol, stirred until completely dissolved, then transferred to the dropping funnel. Add 15g of n-butanol and 0.03g of 2,2'-azobisisobutyronitrile into the three-necked flask. At 90°C, add the mixed liquid dropwise into the flask, and control the liquid in the funnel to add dropwise for about 1 hour. After the dropwise addition is completed, continue heating at constant temperature for 2 hours. Raise the temperature to 100°C, add 0.15 g of initiator 2,2'-azobisisobutyronitrile, and continue the reaction at constant temperature for 1 hour. Cool down to 60°C, add 14.83g of N,N-dimethylethanolamine, and react for 1h. Cool to room temperature after the completion o...

Embodiment 3

[0032] Embodiment 3: the preparation of polymer viscosity reducer P3

[0033] In the three-necked flask, add 12g acrylic acid, 2.0g styrene, 1.8g vinyl silicone oil (5% vinyl, viscosity is 1000cP, purchased from Jinan Xingfeilong Chemical Co., Ltd.), 14.4g octadecyl methacrylate, 0.27g initiator azobisisobutyronitrile, 15g solvent n-butanol, stirred until completely dissolved and then transferred to the dropping funnel. Add 15 g of n-butanol and 0.03 g of initiator azobisisobutyronitrile into the three-necked flask. At 90°C, add the mixed liquid dropwise into the flask, and control the liquid in the funnel to add dropwise for about 1 hour. After the dropwise addition is completed, continue heating at constant temperature for 2 hours. Raise the temperature to 120°C, add 0.15 g of the initiator azobisisobutyronitrile again, and continue the reaction at constant temperature for 7 hours. Cool down to 60°C, add 14.83g of N,N-dimethylethanolamine, and react for 1h. Cool to room t...

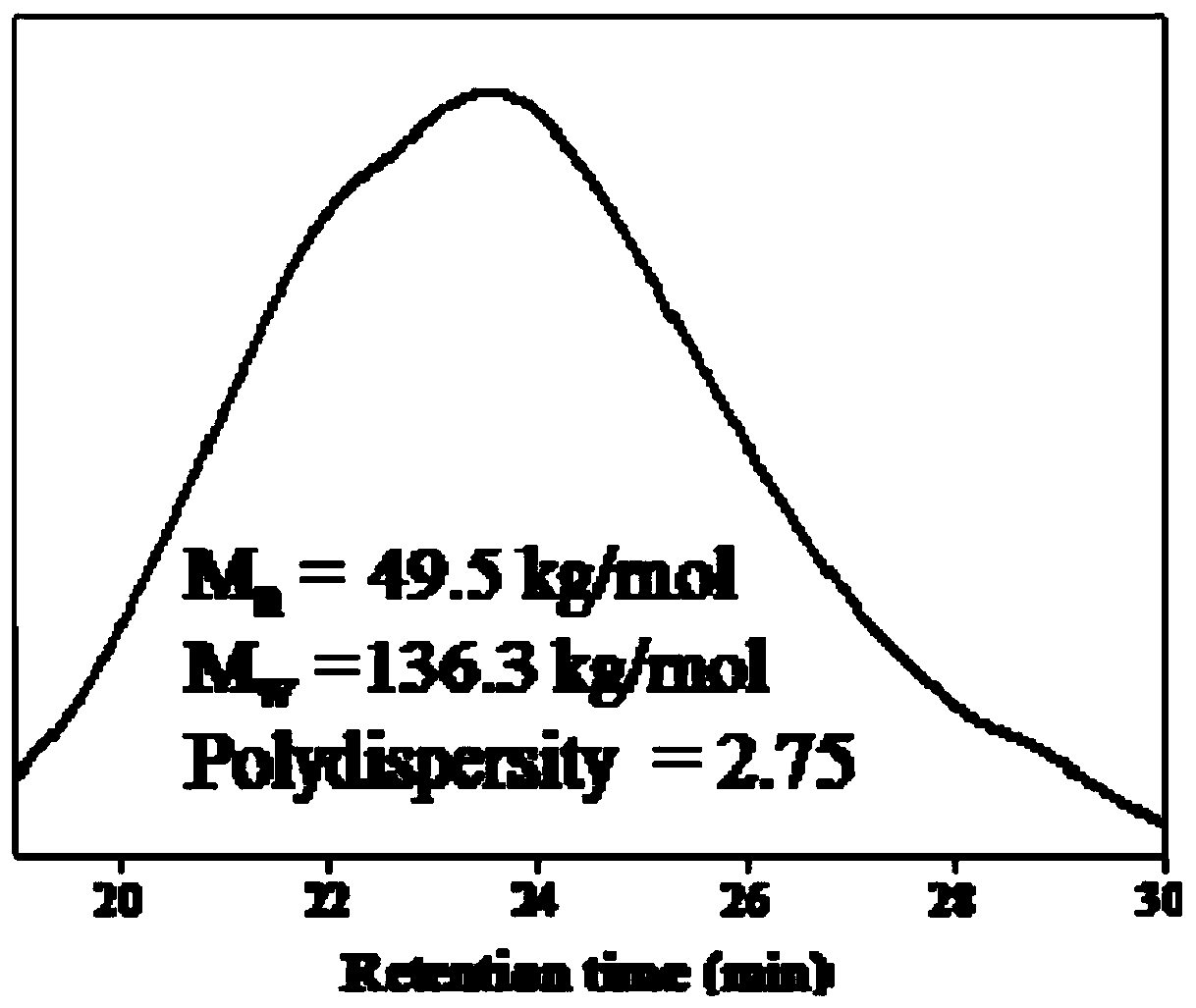

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com