Preparation method and application of titanium dioxide nanorod array/silver nano composite material

A nanorod array, titanium dioxide technology, applied in the field of nanomaterials, can solve the problems of complex operation, high reaction temperature, large electric energy, etc., and achieve the effects of good repeatability, low reaction temperature and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The embodiment of the present invention provides a preparation method of a titanium dioxide nanorod array / silver nanocomposite material, the preparation method comprising:

[0028] Dissolving tetrabutyl titanate in a hydrochloric acid solution to obtain a hydrochloric acid solution of tetrabutyl titanate;

[0029] Put the substrate into the hydrochloric acid solution of tetrabutyl titanate, and conduct a hydrothermal reaction at 140-160°C for 3-10 hours to obtain a titanium dioxide nanorod array. The substrate is fluorine-doped tin dioxide transparent conductive glass (FTO conductive glass);

[0030] putting the titanium dioxide nanorod array into the silver ammonia solution, and standing at room temperature for 4-6 hours to obtain the mixture;

[0031] The ethanol solution of polyvinylpyrrolidone is added into the mixture, and reacted at 60-80° C. for 2-4 hours to obtain titanium dioxide nanorod array / silver nanocomposite material.

[0032] Specifically, the preparati...

Embodiment 1

[0042] The embodiment of the present invention provides a preparation method of a titanium dioxide nanorod array / silver nanocomposite material, the preparation method comprising:

[0043] Mix concentrated hydrochloric acid and deionized water at a volume ratio of 1:1 to obtain a hydrochloric acid solution. Measure 0.8 mL of tetrabutyl titanate with a pipette, and dissolve tetrabutyl titanate in 60 mL of hydrochloric acid solution, and stir for 20 minutes by magnetic force , making the tetrabutyl titanate rapidly dissolve in the hydrochloric acid solution to obtain the hydrochloric acid solution of the tetrabutyl titanate;

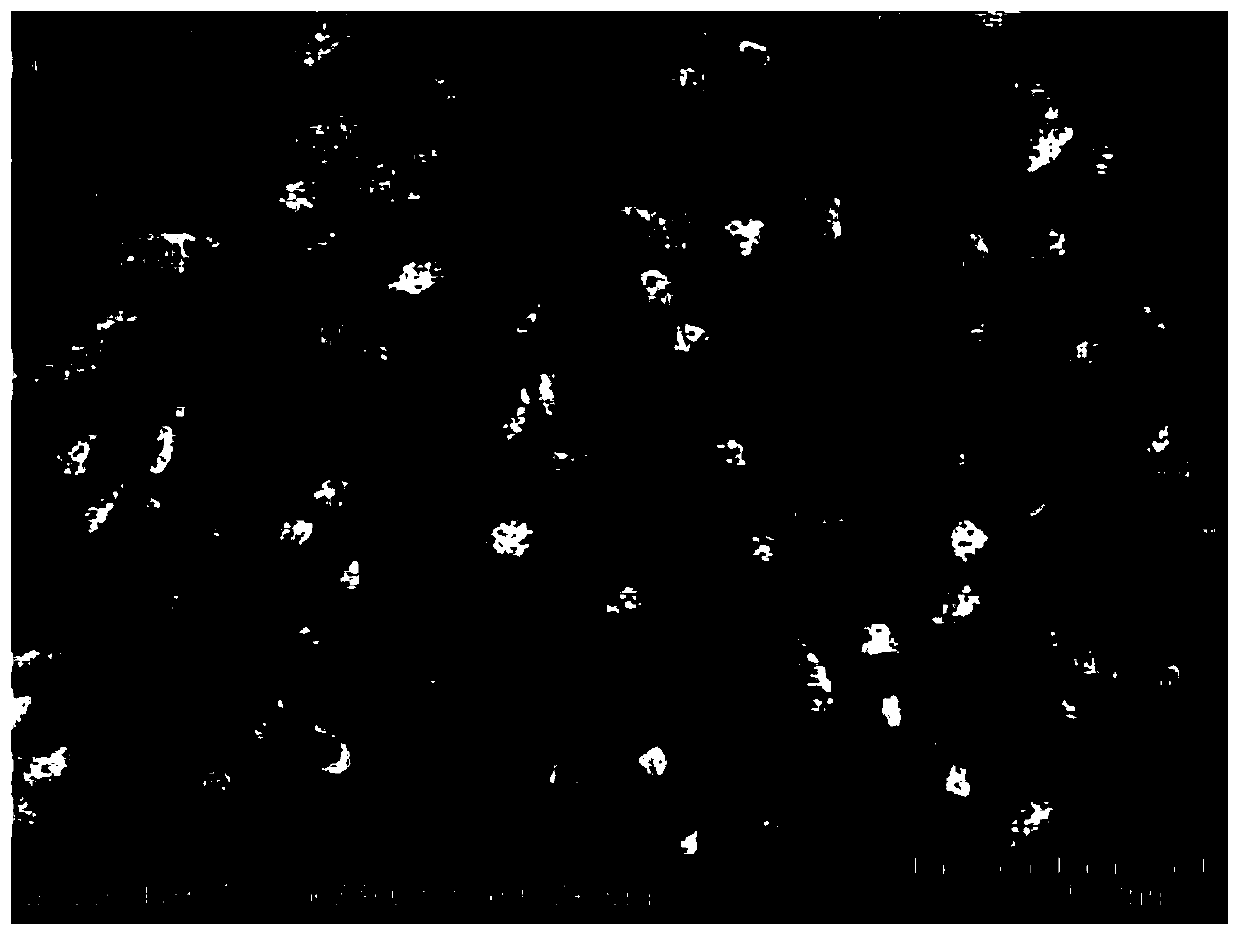

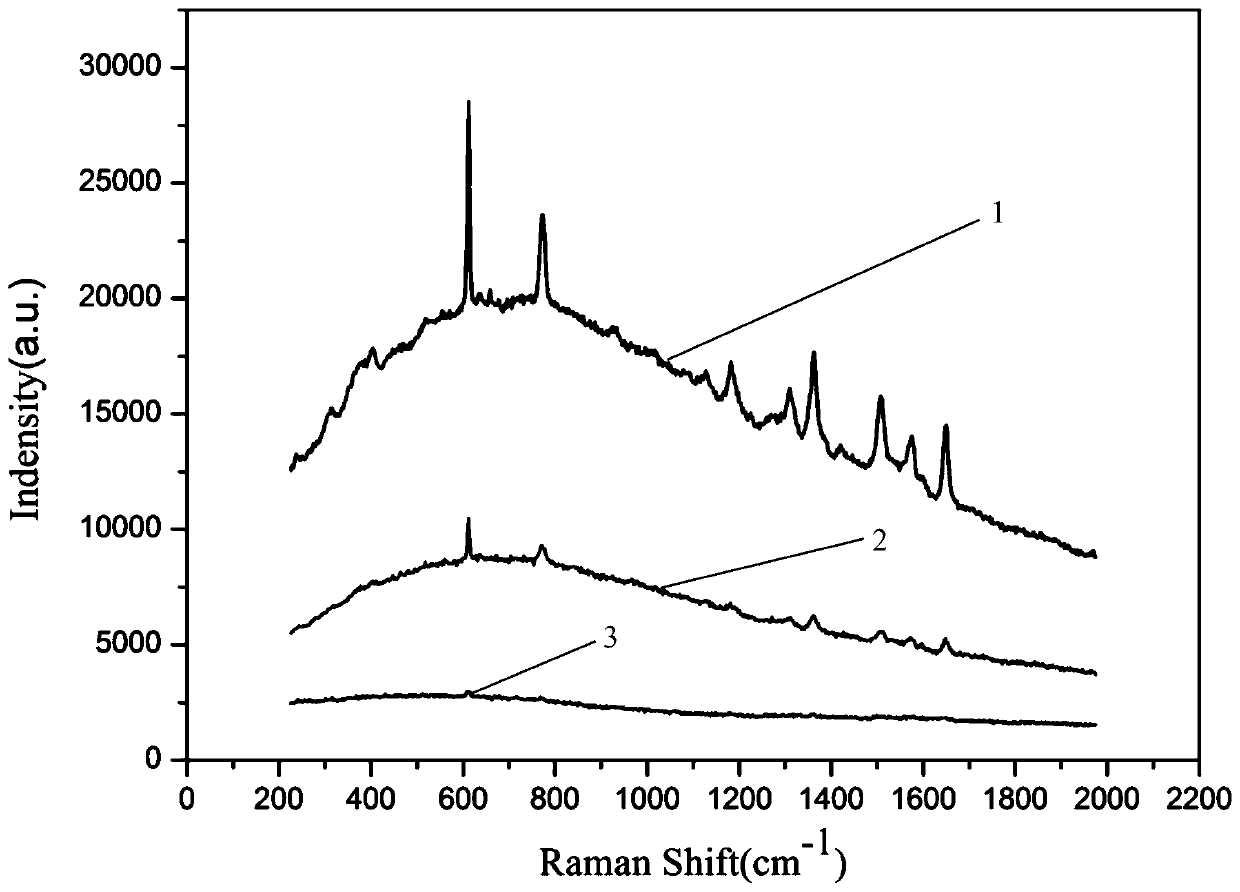

[0044] The substrate was put into the hydrochloric acid solution of tetrabutyl titanate, and hydrothermally reacted at 150°C for 5 hours to obtain a titanium dioxide nanorod array. The substrate was fluorine-doped tin dioxide transparent conductive glass; the prepared titanium dioxide nanorods Rod arrays were characterized as figure 1 Field emission SEM mi...

Embodiment 2

[0052] The embodiment of the present invention provides a preparation method of a titanium dioxide nanorod array / silver nanocomposite material, the preparation method comprising:

[0053] Mix concentrated hydrochloric acid and deionized water at a volume ratio of 1:1 to obtain a hydrochloric acid solution. Measure 0.8 mL of tetrabutyl titanate with a pipette and dissolve tetrabutyl titanate in 60 mL of hydrochloric acid solution. Stir for 15 minutes by magnetic force , making the tetrabutyl titanate rapidly dissolve in the hydrochloric acid solution to obtain the hydrochloric acid solution of the tetrabutyl titanate;

[0054] Put the substrate into the hydrochloric acid solution of tetrabutyl titanate, and conduct a hydrothermal reaction at 140°C for 3 hours to obtain a titanium dioxide nanorod array, and the substrate is tin dioxide-doped transparent conductive glass with fluorine;

[0055] Dissolve silver nitrate and ammonia water in absolute ethanol respectively, and obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com