Method for rapidly etching and analyzing chemical state of material interface elements by using X-ray photoelectron spectrometer

A technology of photoelectron energy spectroscopy and interface elements, which is applied to the analysis of materials, material analysis using wave/particle radiation, instruments, etc., can solve the problems of inability to achieve rapid analysis and cannot truly reflect the chemical state of chemical elements in the film layer, and achieve reduction Analyze overall time, effect of increasing etch speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

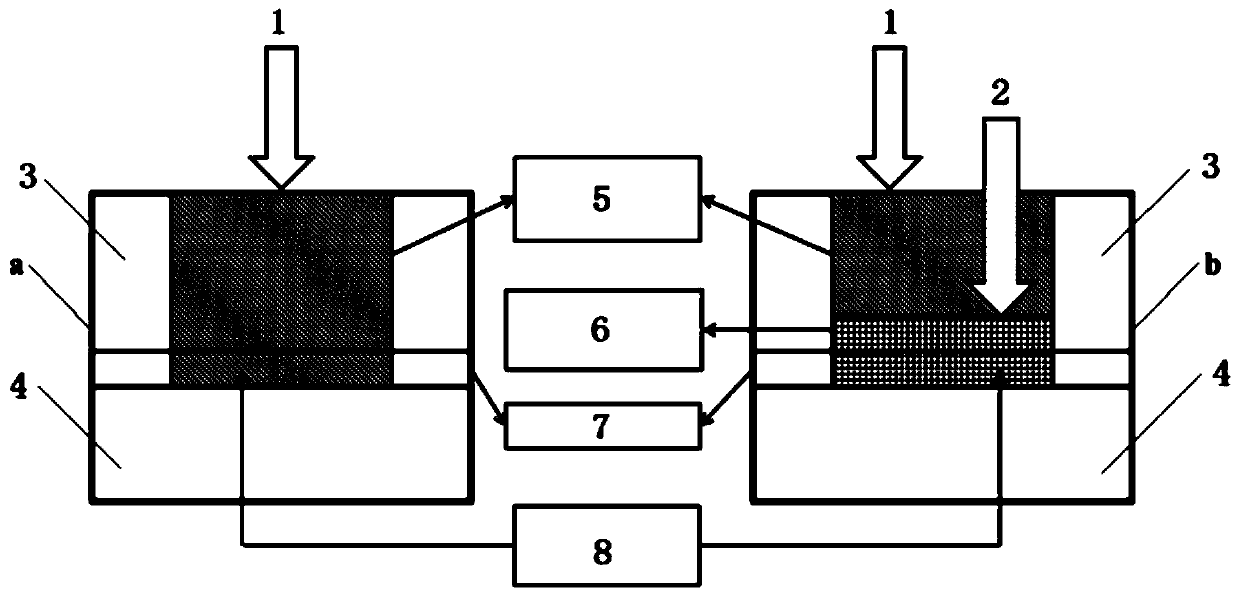

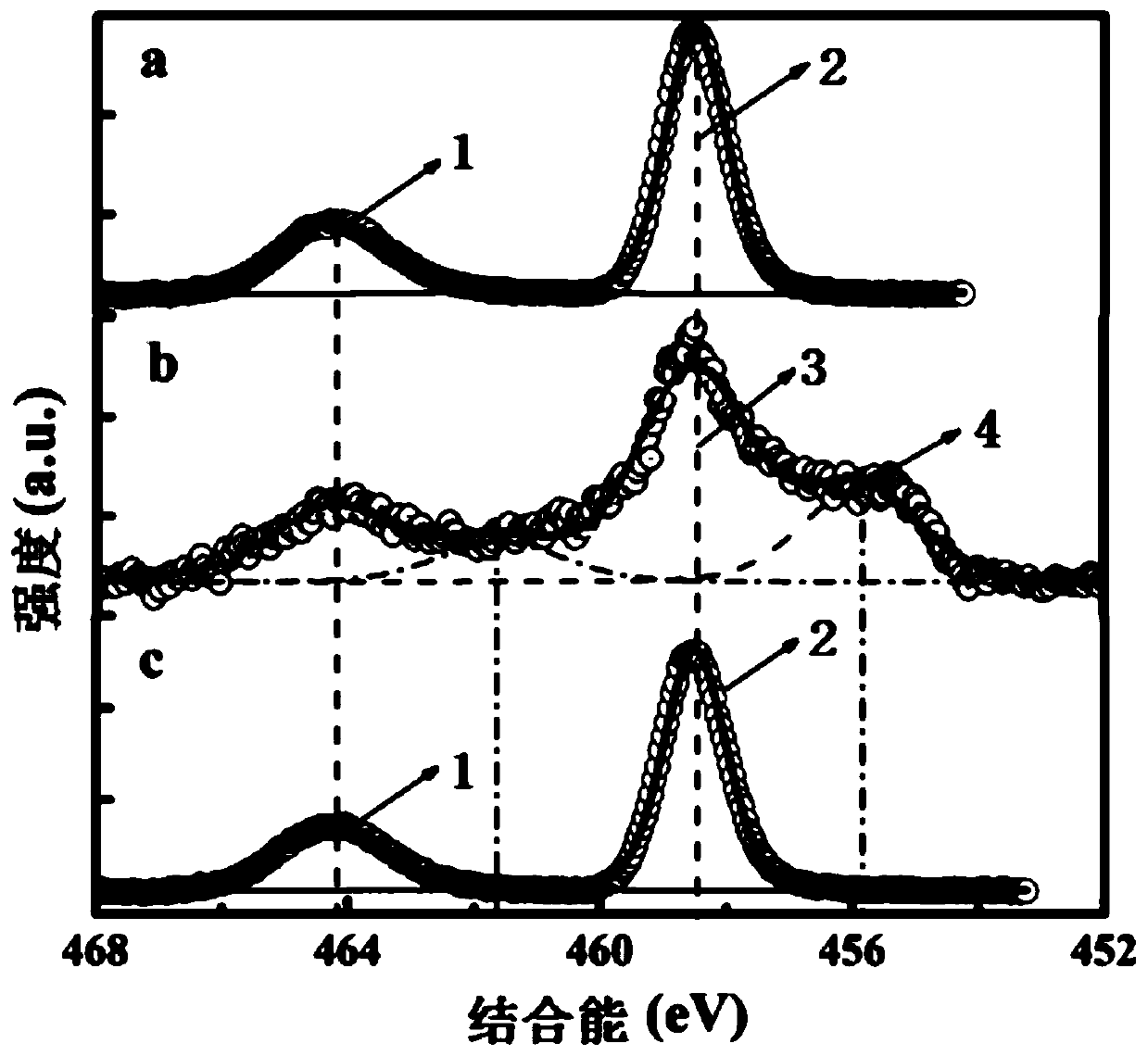

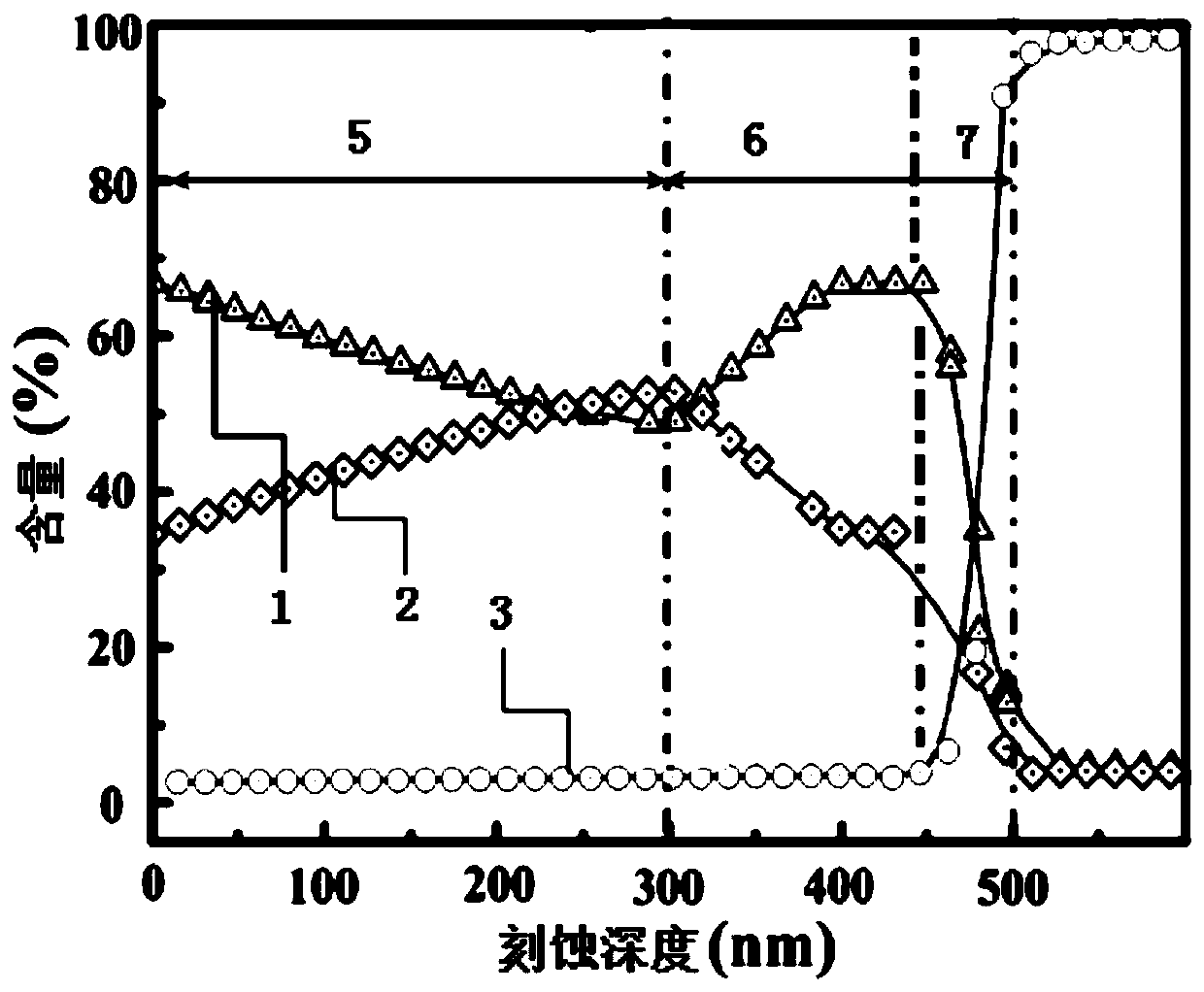

[0017] Specific Embodiment 1: This embodiment is a method for quickly etching and analyzing the chemical state of material interface elements using an X-ray photoelectron spectrometer. It is completed in the following steps:

[0018] 1. Remove the surface layer:

[0019] The material is placed in an X-ray photoelectron spectrometer, and the etching area is selected as 1mm 2 ~4mm 2 , under the condition that the etching rate is 0.05nm / s-0.2nm / s, use Ar ion etching in single-particle mode until the position is 100nm-200nm away from the interface layer;

[0020] The material is composed of n layers of films, n≥2, and n is a positive integer;

[0021] Or the material is a substrate with a film material on the surface, and the film material is composed of m layers of films, m≥1, and m is a positive integer;

[0022] Second, the interface layer analysis:

[0023] Under the condition of etching speed of 0.0005nm / s~0.001nm / s, use Ar ion in cluster mode to etch to the interface lay...

specific Embodiment approach 2

[0029] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the energy of the single particle mode described in Step 1 is 1000 eV-4000 eV. Others are the same as the first embodiment.

specific Embodiment approach 3

[0030] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the energy of the cluster mode described in step 2 is 500 eV-4000 eV. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com