Pixel structure of CMOS image sensor and forming method of pixel structure

An image sensor and pixel structure technology, applied in the field of image sensors, can solve problems such as the aperture ratio needs to be improved, and achieve the effect of improving the aperture ratio and quantum efficiency, and improving the signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] As mentioned in the background, the aperture ratio (Fill Factor, FF) of the existing CMOS image sensor pixels still needs to be improved.

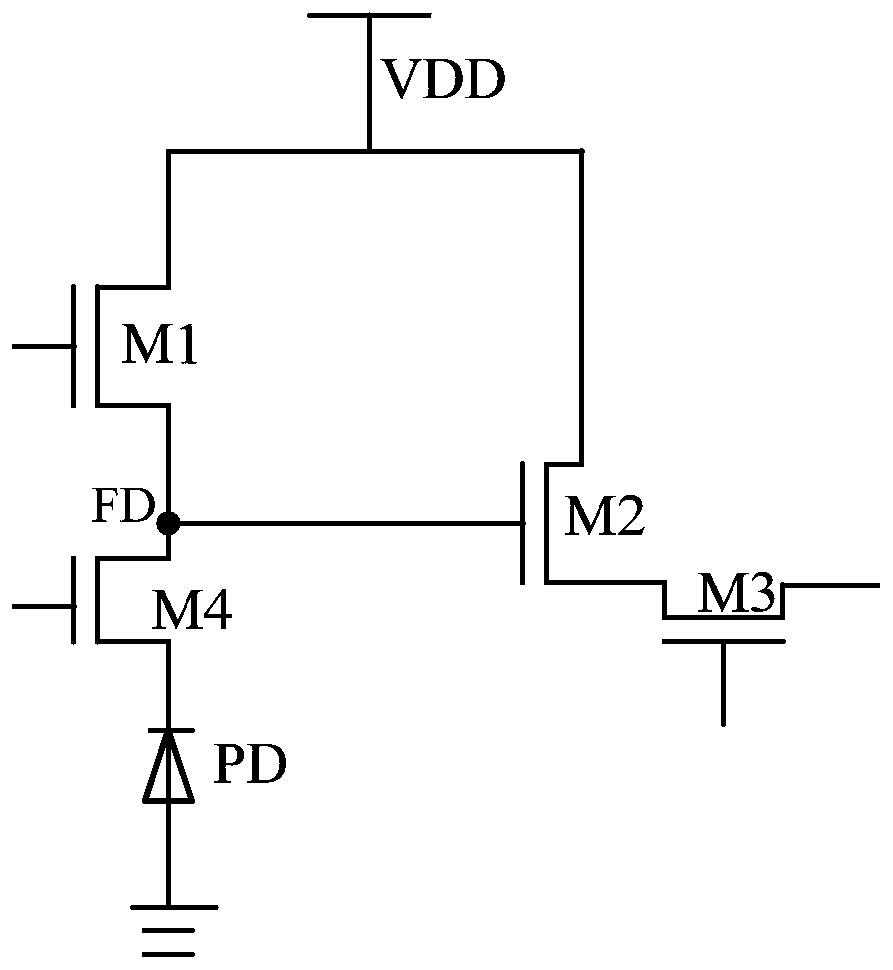

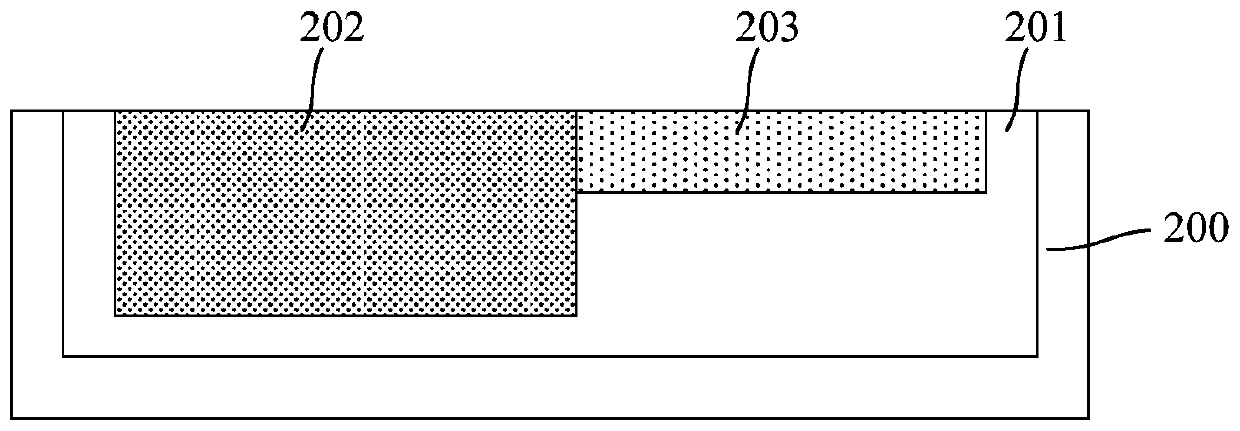

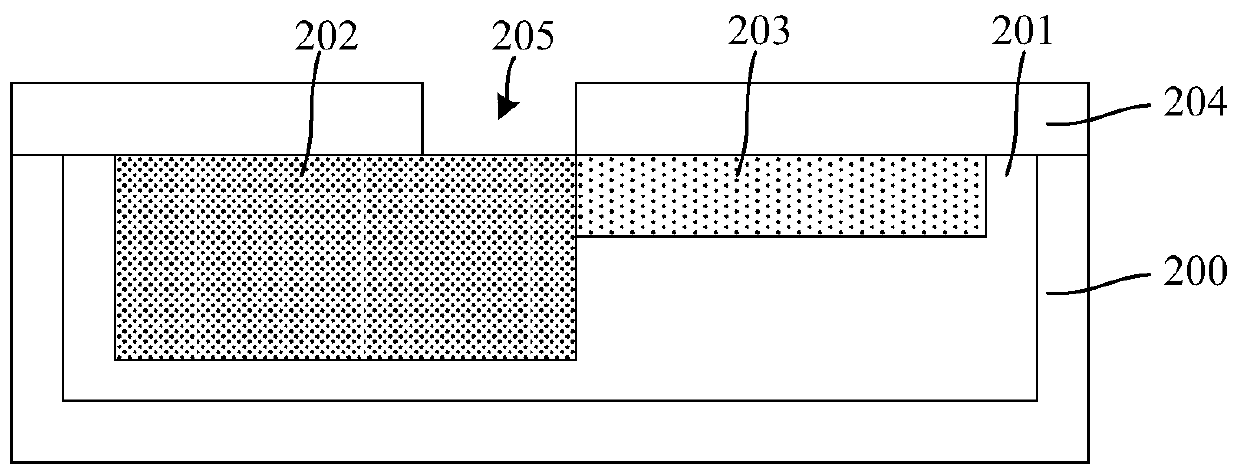

[0042]The study found that the pixel structure of the existing front-illuminated CMOS image sensor includes 1 photodiode and 4 transistors, and only the photodiode is used to sense light and generate photogenerated carriers. Therefore, the area of the photodiode in the pixel structure occupies the entire pixel The ratio of the area of the structure is directly related to the quantum efficiency and signal-to-noise ratio of the CMOS image sensor. The industry also refers to the ratio of the area of the photodiode in the pixel structure to the area of the entire pixel structure as the fill factor (FillFactor, FF) or aperture ratio. , the larger the fill factor (Fill Factor, FF) or aperture ratio, the higher the quantum efficiency and signal-to-noise ratio. The grid makes it difficult to further increase the fill factor (Fill Fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com