Method for recovering copper in waste circuit board

A waste circuit board and recycling method technology, which is applied in the field of copper recycling in waste circuit boards, can solve a large amount of waste water and waste gas, environmental pollution, sewage and other problems, and achieve the effect of ingenious design and avoid waste gas and waste water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings, so that those skilled in the art can implement it with reference to the description.

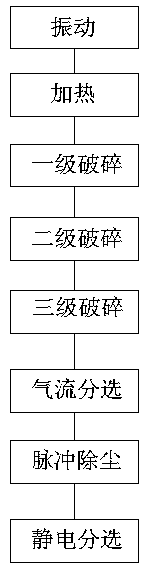

[0026] The embodiment of the invention discloses a method for recovering copper in waste circuit boards, comprising the following steps:

[0027] Step 1): The waste circuit board is sent into the vibrating device for vibration, and the dust generated in the vibrating device is sucked by the dust suction device connected with the vibrating device; the dirt on the waste circuit board can be removed from the waste through the vibration mode. The circuit board is shaken off, and the dust generated by the vibration can be sucked out by the vacuum equipment, which can reduce the dirt in the waste circuit board and prepare for the following process;

[0028] Step 2): Send the waste circuit boards in step 1) to the primary crusher for crushing. The primary crusher cru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com