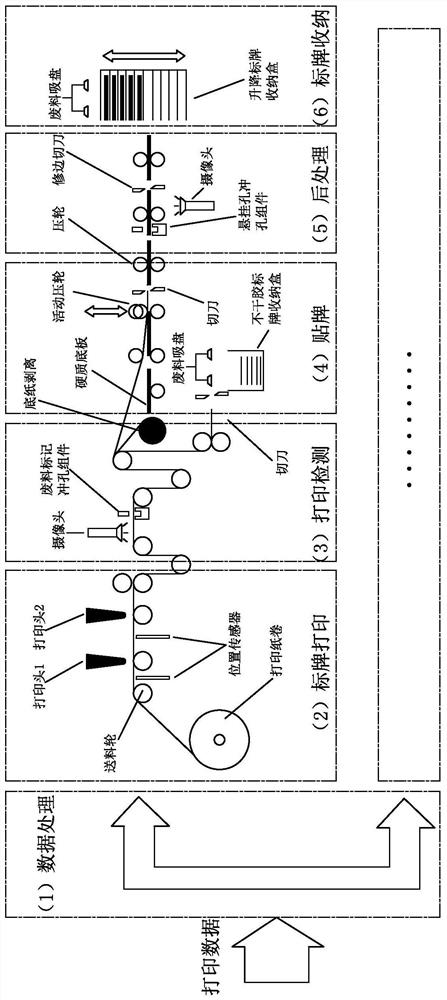

Automated label production method and assembly line production equipment

A production equipment and assembly line technology, applied in the field of signage, can solve problems such as low production efficiency, high production labor costs, and many process flows, and achieve the effects of high production efficiency, improved signage quality, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

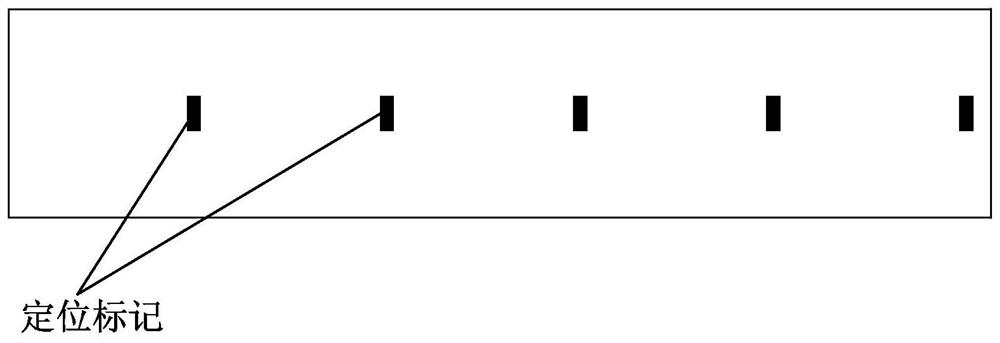

[0075] The production line equipment for automatic production of signs of the present invention is mainly used for printing signs for various warnings, reminders, reminders and marking purposes by using thermal transfer technology. The soft sign formed on the carrier can also be a hard sign formed by printing the printed content on a soft carrier affixed to a hard base.

[0076] The soft carrier is usually composed of a printing surface layer made of plastic film or paper, a self-adhesive layer and a release paper. The logo content is printed on the printing surface layer, and the self-adhesive layer is arranged on the back of the printing surface layer. The liner is used to protect the self-adhesive layer from environmental dust or moisture contamination. When using, peel off the release paper and stick the self-adhesive layer on the target.

[0077] Thermal transfer technology is embodied by thermal transfer printers, which use a special carbon ribbon with a single color to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com